Silicone coating capable of resisting low temperature of -40DEG C, and preparation method thereof

A production method and silicone technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as difficult to meet the use requirements and deficiencies, and achieve the effects of non-toxic skin, strong hydrophobicity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a silicone coating resistant to low temperatures of -40°C, the composition of which is as follows in terms of mass percentage:

[0038] Grafted silicone resin 44%

[0039] 50μm aluminum powder 42%

[0040] Styrene 3%

[0041] Aluminum powder alignment agent LY-610 7.5%

[0042] KH570 silane coupling agent 3.5%

[0043] This embodiment also provides a method for preparing a silicone coating resistant to low temperatures of -40°C. The steps of the method are as follows:

[0044] Step (1): Put the grafted silicone resin and additives into the dispersion tank filled with solvent, start the agitator to stir slowly, the stirring speed is 300 rpm, after stirring for 20 minutes, wait until it is uniform;

[0045] Step (2): Add aluminum powder to the homogeneous mixture in step (1) by adding it in the state of stirring, adjust the rotation speed to 600 rpm, and stir for 50 minutes, and wait until it is uniform;

[0046] Step (3): Control the tempera...

Embodiment 2

[0050] This embodiment provides a silicone coating resistant to low temperatures of -40°C, the composition of which is as follows in terms of mass percentage:

[0051] Grafted silicone resin 40%

[0052] 50μm aluminum powder 45%

[0053] Styrene 5%

[0054] SP-1004 aluminum powder alignment agent 7%

[0055] KH580 silane coupling agent 3%

[0056] This embodiment also provides a method for preparing a silicone coating resistant to low temperatures of -40°C. The steps of the method are as follows:

[0057]Step (1): Put the grafted silicone resin and additives into the dispersion tank filled with solvent, start the agitator to stir slowly, the stirring speed is 300 rpm, after stirring for 30 minutes, wait until it is uniform;

[0058] Step (2): Add aluminum powder to the homogeneous mixture in step (1) by adding it in the state of stirring, adjust the rotation speed to 600 rpm, and stir for 30 minutes, and wait until it is uniform;

[0059] Step (3): Control the temperature...

Embodiment 3

[0063] This embodiment provides a silicone coating resistant to low temperatures of -40°C, the composition of which is as follows in terms of mass percentage:

[0064] Grafted silicone resin 50%

[0065] 50μm aluminum powder 40%

[0066] Trichlorostyrene 5%

[0067] SP-1004 aluminum powder alignment agent 3.5%

[0068] KH580 silane coupling agent 1.5%

[0069] The present invention also provides a method for preparing a silicone coating resistant to low temperatures of -40°C. The steps of the method are as follows:

[0070] Step (1): Put the grafted silicone resin and additives into the dispersion tank filled with solvent, start the agitator to stir slowly, the stirring speed is 300 rpm, after stirring for 50 minutes, wait until it is uniform;

[0071] Step (2): Add aluminum powder to the homogeneous mixture in step (1), the way is to add it under stirring, adjust the rotation speed to 600 rpm, stir for 20 minutes, and wait until it is uniform;

[0072] Step (3): Control ...

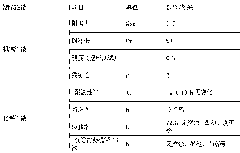

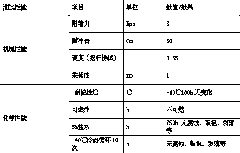

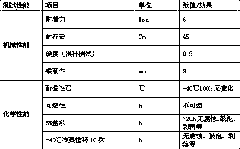

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com