EVA composite material applied to high jump mat and preparation method thereof

A composite material and high jump technology, which is applied in the field of sports materials, can solve problems such as poor elasticity, tear resistance and peel resistance, unfavorable health of athletes, and a large number of bacteria breeding, etc., to achieve good elasticity, uniform foaming, and bubble cells fine and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

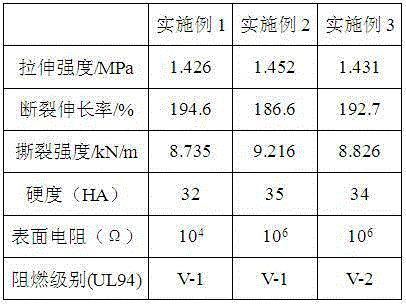

Examples

Embodiment 1

[0031] A preparation method for high jump pad EVA composite material, comprising the following steps:

[0032] Step 1. Put the foaming agent powder in a kneader preheated to 50°C, and add an auxiliary agent whose weight is 1.5% of the weight of the foaming agent powder into the kneader, and continue heating until the temperature in the kneader reaches 100°C. After heating at this temperature for 25 minutes, discharge and granulate to obtain foaming agent masterbatches for later use; wherein, the auxiliary agent is composed of calcium carbonate, zinc oxide and carrier EVA in a weight ratio of 13:1:5;

[0033] Step 2: Take the silver-loaded zirconium phosphate powder and bake it at 80°C for 2 hours, then add it to a high-speed mixer pre-heated to 90°C, control the stirring speed at 270r / min, stir for 10min, and follow the aluminate coupling agent : silver-loaded zirconium phosphate powder = 1.5: 100 weight ratio to weigh the aluminate coupling agent, and take the aluminate coupl...

Embodiment 2

[0039] A preparation method for high jump pad EVA composite material, comprising the following steps:

[0040] Step 1. Put the blowing agent powder in a kneader preheated to 50°C, and add an auxiliary agent whose weight is 2% of the blowing agent powder weight into the kneader, and continue heating until the temperature in the kneader reaches 100°C. After heating at this temperature for 23 minutes, discharge and granulate to obtain foaming agent masterbatch, wherein the auxiliary agent is composed of calcium carbonate, zinc oxide and carrier EVA in a weight ratio of 12:1:5, and is ready for use;

[0041] Step 2: Take the silver-loaded zirconium phosphate powder and bake it at 80°C for 2 hours, then add it to a high-speed mixer pre-heated to 86°C, control the stirring speed at 250r / min, stir for 10 minutes, and follow the aluminate coupling agent : silver-loaded zirconium phosphate powder=3:100 weight ratio to weigh the aluminate coupling agent, and take the aluminate coupling ...

Embodiment 3

[0047] A preparation method of EVA composite material for a high jump mat, comprising the following steps: Step 1, placing foaming agent powder in a kneader preheated to 50°C, and adding 0.2 % additives, continue to heat until the temperature in the kneader reaches 100°C, and after heating at this temperature for 20 minutes, discharge and granulate to obtain foaming agent masterbatches for later use; wherein, the weight ratio of additives is 14: 1:5 composition of calcium carbonate, zinc oxide and carrier EVA.

[0048] Step 2: Take the silver-loaded zirconium phosphate powder and bake it at 80°C for 2 hours, then add it to a high-speed mixer pre-heated to 80°C, control the stirring speed at 300r / min, stir for 10 minutes, and follow the aluminate coupling agent : silver-loaded zirconium phosphate powder = 1.3: 100 weight ratio to weigh the aluminate coupling agent, and take the aluminate coupling agent and ethanol in sequence according to the ratio of 1g: 3.2mL, mix them into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com