Modified PET plastic and preparation method thereof

A plastics and modification technology, applied in the field of modified PET plastics and its preparation, can solve the problems of adverse effects on the quality of PET products, poor impact strength and fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

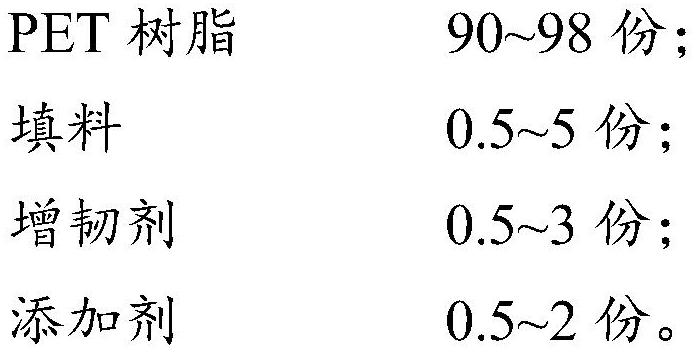

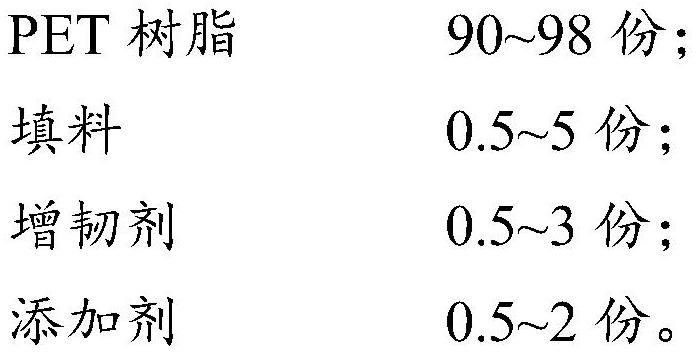

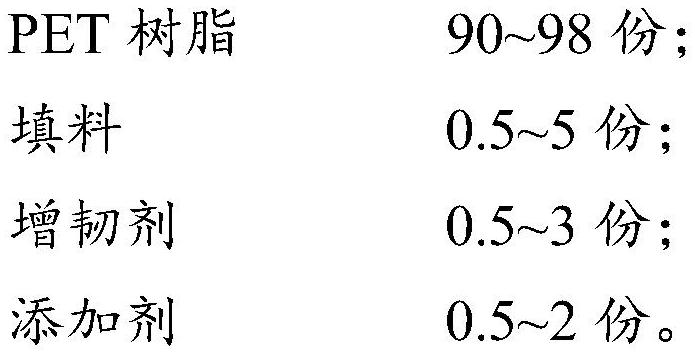

Method used

Image

Examples

preparation example Construction

[0025] In a specific embodiment of the present invention, the preparation method of the NCO-terminated polyurethane prepolymer includes: under the protection of a nitrogen atmosphere, mixing polyols and polyisocyanates, and performing a polymerization reaction to obtain an NCO-terminated polyurethane prepolymer. In the present invention, the polyol is preferably polyester polyol, specifically neopentyl glycol (NPG). In the present invention, the molar ratio of the hydroxyl group of the polyol to the NCO of the polyisocyanate is preferably 1:1.5˜4.5. In the present invention, the temperature of the polymerization reaction is preferably 80-100°C.

[0026] In the present invention, based on the parts by weight of the PET resin, the raw materials for preparing the modified PET plastic include 0.5-2 parts of additives, preferably 0.6-1.1 parts. In the present invention, the additives preferably include compatibilizers, release agents and / or stabilizers. In the present invention, ...

Embodiment 1

[0034] The preparation method of terminal NCO polyurethane prepolymer:

[0035] Remove a small amount of water from NPG, under the protection of nitrogen atmosphere, add NPG to excess MDI, stir and disperse the product, and take away a lot of heat at the same time, stop adding when the NCO content of the isocyanate is 1.5 to 4.5 times the OH content of the added polyol Polyol, the reaction temperature is 80-100 DEG C, and the terminal NCO polyurethane prepolymer is obtained.

[0036] In parts by weight, 94.9 parts of PET resin, 1 part of nano-silica, 3 parts of terminal NCO polyurethane prepolymer, 0.5 part of calcium stearate, 0.3 part of PETS and 0.3 part of antioxidant BASF 1076 are mixed, all Add a high-speed mixer and stir for 5 minutes at a speed of 150r / min to obtain a premix; put the premix into a twin-screw extruder through the main feeding port for co-extrusion, and the barrel temperature of the twin-screw extruder is 130 ~ 180°C, the screw speed is 300-400r / min, th...

Embodiment 2

[0038] In parts by weight, 94.9 parts of PET resin, 1 part of nano-silica, 0.5 part of nano-sodium bicarbonate, 3 parts of terminal NCO polyurethane prepolymer prepared in Example 1, 0.3 part of PETS and 0.3 part of antioxidant BASF 1076 for mixing, all added to a high-speed mixer, and stirred at 150r / min for 5 minutes to obtain a premix; the premix was added to a twin-screw extruder through the main feeding port for co-extrusion, and the twin-screw extruder material The barrel temperature is 130-180°C, the screw speed is 300-400r / min, the vacuum degree is 0.5-0.8MPa, and the screw length-to-diameter ratio is 40 to obtain the modified PET plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com