High-density polyethylene composition and preparation method thereof

A technology of high-density polyethylene and composition is applied in the field of high-density polyethylene composition and its preparation, and achieves the effects of improving flame retardant performance, simple preparation process and easy operation of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of high-density polyethylene composition, comprises the steps:

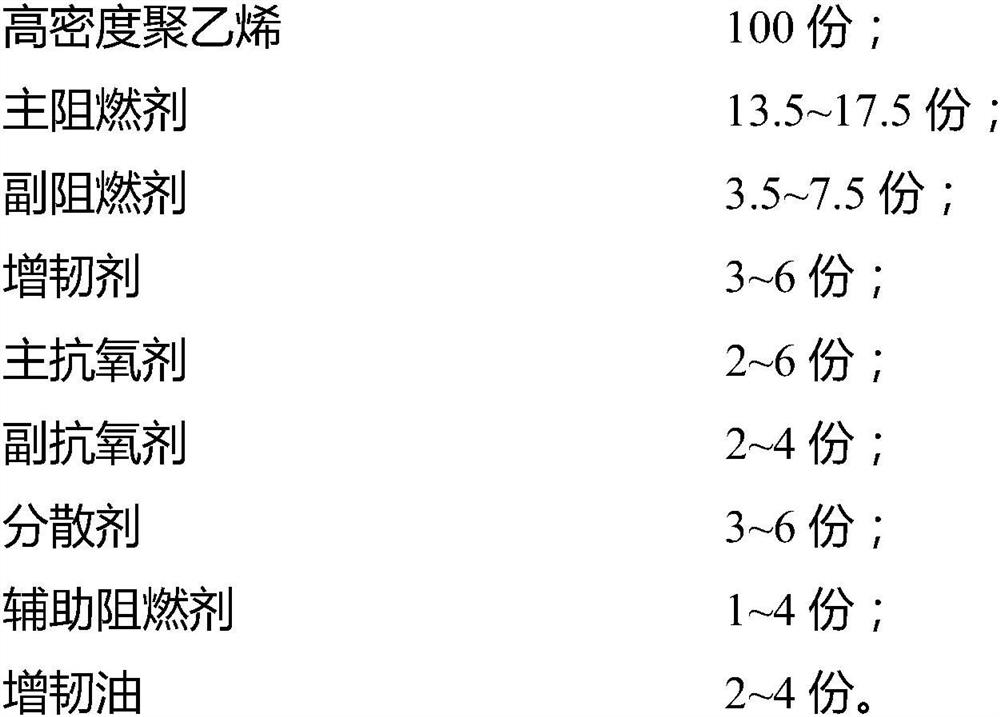

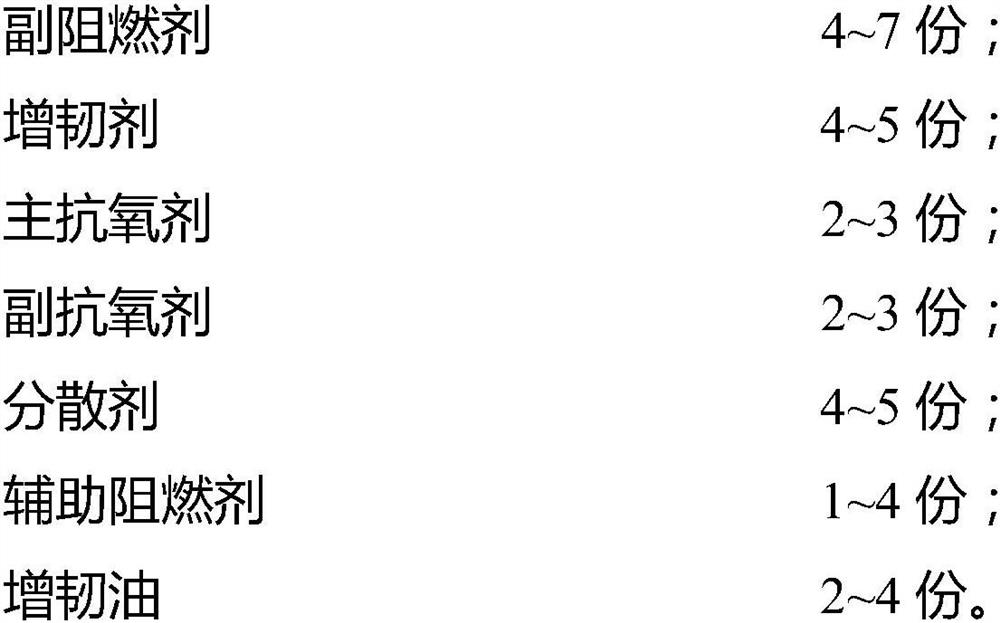

[0039] (1) According to the formulation amount shown in Table 1, take the raw material high-density polyethylene (B5703 of Beijing Yanshan Petrochemical), primary flame retardant, secondary flame retardant, toughening agent, primary antioxidant, secondary antioxidant , dispersant, auxiliary flame retardant and toughening oil; the main flame retardant is decabromodiphenylethane; the secondary flame retardant is antimony trioxide; the toughening agent is thermoplastic elastomer POE ( 8150 of Dow Dupont); The main antioxidant is 1010; The secondary antioxidant is 168; The dispersant is EBS; The auxiliary flame retardant is zinc borate and anti-dripping agent mixture; The toughening oil is A-608; add the above raw materials into the mixer in turn, and stir at high speed for 5-8 minutes to obtain the mixed material;

[0040] (2) Add the mixed material in step (1) to a twin-screw ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com