Machine vision based automatic defect detection method for train tunnel cable clamp

A machine vision, tunnel cable technology, applied in the field of image processing, can solve the problems of insecurity, many tunnel sections, slow speed, etc., and achieve the effect of rapid opening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

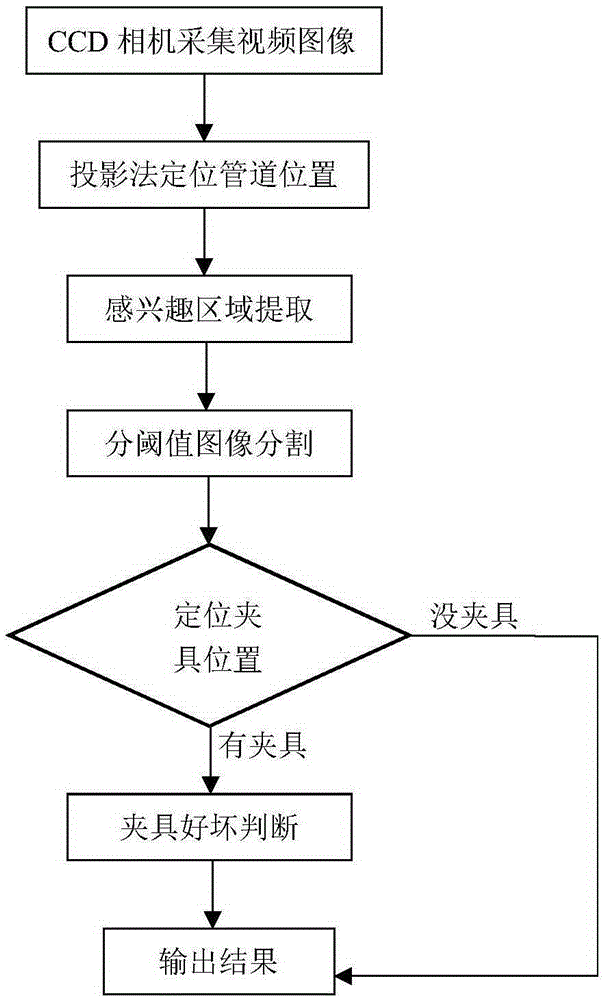

[0028] figure 1 Implement the flowchart for the system algorithm, including the algorithm flow of video image acquisition and subsequent image processing.

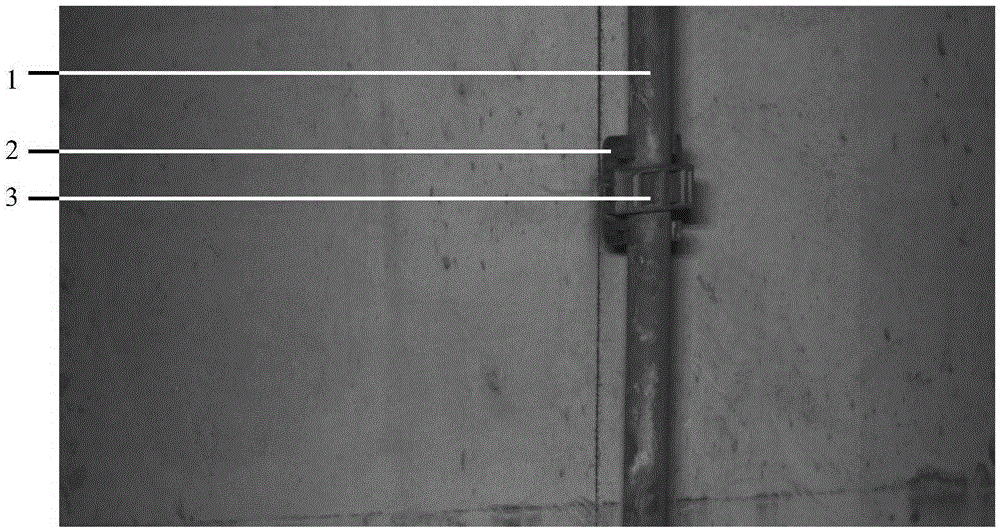

[0029] figure 2 Here is an example image of a good fixture, with pipes (1), fixtures (2), and fixture cards (3).

[0030] First, the video image is collected by the CCD camera (acquired through the above step 1), and then the collected video image is decomposed into a single frame image, and input into the algorithm by frame, and then X-axis projection is performed on the image, and the projection curve is as follows: image 3 shown. (Since the camera is placed in this example, in order to make the image of the cable in the image as long as possible, the camera is placed horizontally, that is, the vertical direction on the image is the actual horizontal direction, and the horizontal direction in the image is the actual horizontal direction. Vertically).

[0031] Next, determine the pipeline position according to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com