Cleaning agent for stainless steel hot-rolled member and preparation method thereof

A stainless steel and cleaning agent technology, applied in the field of chemical cleaning, can solve the problems of waste acid water pollution of water resources, air pollution, human hazards, etc., to achieve the effect of ensuring personal safety, no harm to skin contact, and strong cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

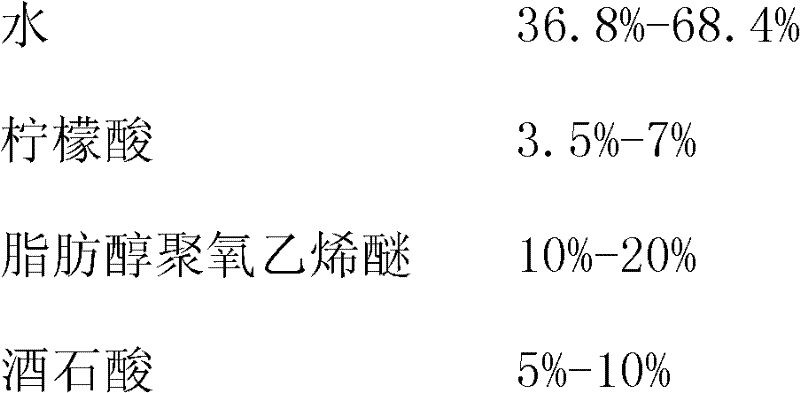

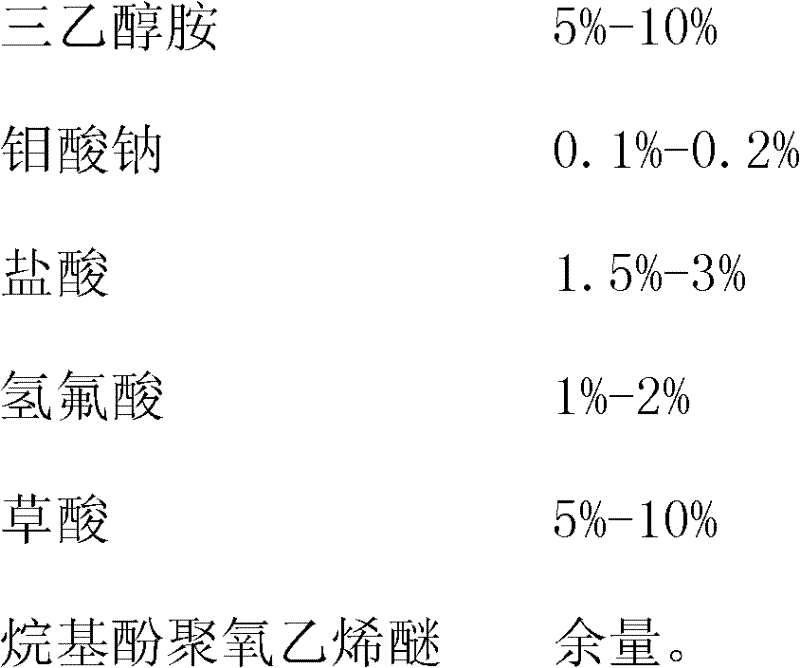

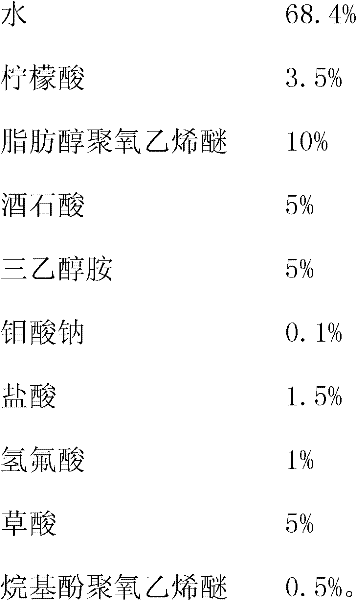

[0028] A preparation method of a cleaning agent for stainless steel hot-rolled parts, which has the following steps: (1), at normal temperature, add 684 kilograms of water in a mixer; (2), add 35 kilograms of citric acid with a content of 99.3% while stirring; 3), throw in 100 kilograms of JFC penetrants while stirring; (4), throw in 50 kilograms of tartaric acid while stirring; (5), throw in content while stirring and be 50 kilograms of 85% triethanolamine; (6), throw in while stirring Content is 1 kilogram of 99% sodium molybdate; (7), adding content while stirring is 15 kilograms of 31% hydrochloric acid; (8), adding content while stirring is 10 kilograms of 90% hydrofluoric acid; (9), stirring Add 50 kilograms of 0.5% oxalic acid while stirring; (10), add 5 kilograms of emulsifier OP-10 while stirring; (11), stir for 20-30 minutes after all the additions are finished to be the finished product.

Embodiment 2

[0030] A preparation method of a cleaning agent for stainless steel hot-rolled parts, which has the following steps: (1), at normal temperature, add 521.5 kilograms of water in a mixer; (2), add 50 kilograms of citric acid with a content of 99.3% while stirring; 3), throw in 150 kilograms of JFC penetrants while stirring; (4), throw in 75 kilograms of tartaric acid while stirring; (5), throw in content while stirring and be 85 kilograms of 85% triethanolamine; (6), throw in while stirring Content is 1.5 kilograms of 99% sodium molybdate; (7), adding content while stirring is 20 kilograms of 31% hydrochloric acid; (8), adding content while stirring is 15 kilograms of 90% hydrofluoric acid; (9), stirring Adding 75 kilograms of 0.5% oxalic acid while stirring; (10), adding 7 kilograms of emulsifier OP-10 while stirring; (11), stirring for 20-30 minutes after all the feeding is finished to be the finished product.

Embodiment 3

[0032] A preparation method of a cleaning agent for stainless steel hot-rolled parts, which has the following steps: (1), at normal temperature, add 431 kilograms of water in the mixer; (2), add 60 kilograms of citric acid with a content of 99.3% while stirring; 3), throw in 180 kilograms of JFC penetrants while stirring; (4), throw in 90 kilograms of tartaric acid while stirring; (5), throw in content while stirring and be 90 kilograms of 85% triethanolamine; (6), throw in while stirring Content is 2 kilograms of 99% sodium molybdate; (7), stirring while putting in content is 25 kilograms of 31% hydrochloric acid; (8), stirring while putting in content is 18 kilograms of 90% hydrofluoric acid; (9), stirring Add 95 kilograms of 0.5% oxalic acid while stirring; (10), add 9 kilograms of emulsifier OP-10 while stirring; (11), stir for 20-30 minutes after all the materials are added to be the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com