An aluminium-alloy pipe descaling treating fluid

A technology of aluminum alloy tube and treatment liquid, which is applied in the field of chemical cleaning, can solve the problems of waste acid water polluting water resources, air pollution, human hazards, etc., and achieves the effects of good cleaning effect, simple operation and cost saving

Inactive Publication Date: 2014-10-22

苏州华创特材股份有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in order to remove the dirt on aluminum alloy pipes, the traditional cleaning agent formula is to mix nitric acid, hydrofluoric acid, hydrochloric acid and water at a mass percentage of 5:4:3:8 and then heat it to 90°C-95°C. The aluminum alloy can be cleaned after soaking for 4-4.5 hours, and only 40-45 tons of aluminum alloy pipes can be cleaned in 8 hours, which is not efficient, and because nitric acid, hydrofluoric acid and hydrochloric acid are heated to produce acid mist, it has great harm to the human body. Harmful, seriously pollutes the air, and the discharge of waste acid water also seriously pollutes water resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

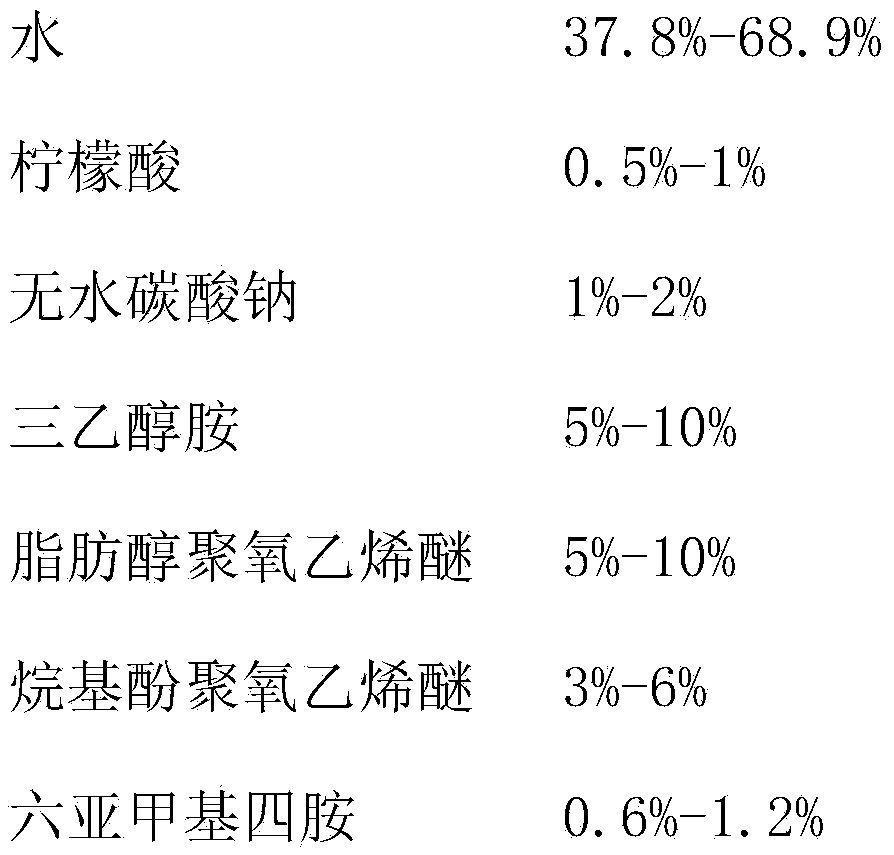

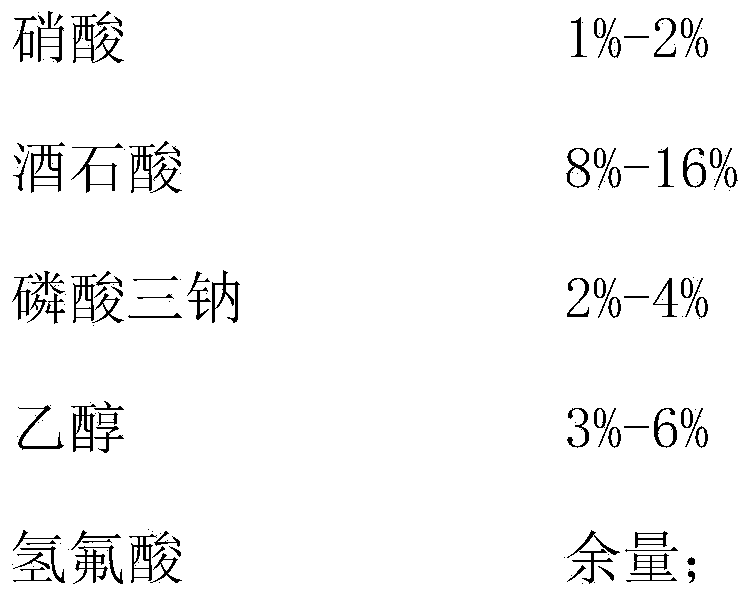

[0018] A descaling treatment liquid for aluminum alloy pipes, the raw materials per ton are:

[0019]

[0020]

Embodiment 2

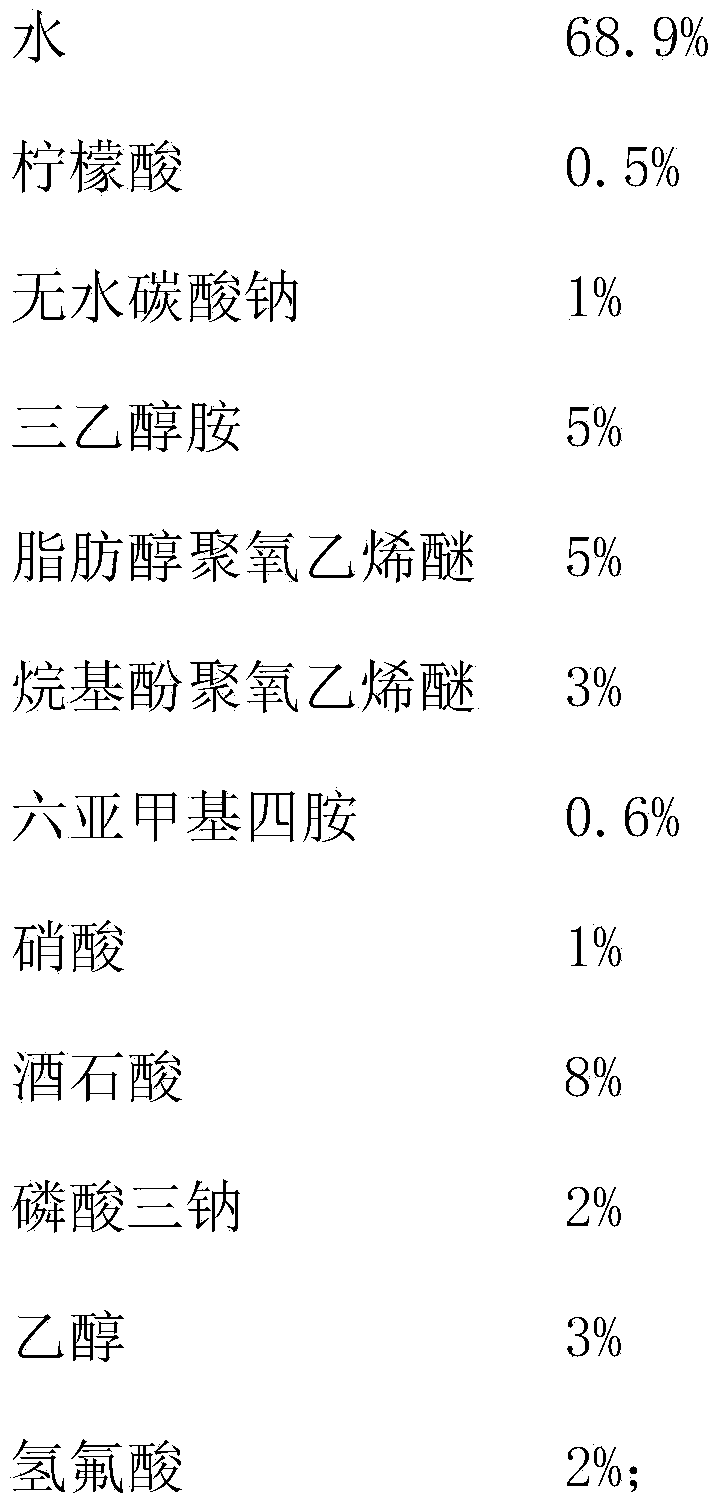

[0022] A descaling treatment liquid for aluminum alloy pipes, the raw materials per ton are:

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

An aluminium-alloy pipe descaling treating fluid is disclosed. The descaling treating fluid is prepared by mixing raw materials by weight at room temperature as follows: 37.8-68.9% of water, 0.5-1% of citric acid, 1-2% of anhydrous sodium carbonate, 5-10% of triethanolamine, 5-10% of polyoxyethylene alkyl ether, 3-6% of alkylphenol polyoxyethylene, 0.6-1.2% of hexamine, 1-2% of nitric acid, 8-16% of tartaric acid, 2-4% of trisodium phosphate and 3-6% of ethanol, with the balance being hydrofluoric acid. The descaling treating fluid has characteristics of simple operation, no need of heating, good cleaning effects, no corrosion to surfaces of aluminium-alloy pipes, capability of maintaining glossiness, capability of being repeatedly used, no harm to skin when contacting skin, low carbon, and capability of protecting the environment and saving the cost.

Description

Technical field [0001] The invention relates to the technical field of chemical cleaning, in particular to a descaling treatment liquid suitable for aluminum alloy tubes. Background technique [0002] At present, in order to remove the dirt of aluminum alloy pipes, the traditional cleaning agent formula is to mix nitric acid, hydrofluoric acid, hydrochloric acid and water at a mass percentage of 5:4:3:8 and then heat to 90℃-95℃. The aluminum alloy can be cleaned by soaking for 4-4.5 hours, and only 40-45 tons of aluminum alloy tubes can be cleaned in 8 hours. The efficiency is not high, and the acid mist generated by nitric acid, hydrofluoric acid and hydrochloric acid after heating has great effects on the human body. Harm, seriously pollute the air, and the discharge of waste acid water also seriously pollutes water resources. Summary of the invention [0003] The technical problem to be solved by the present invention is to overcome the shortcomings of the prior art and provid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23G5/036

Inventor 韩波李根为

Owner 苏州华创特材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com