Ceramic cleaning agent and preparation method thereof

A cleaning agent and ceramic technology, applied in the field of cleaning, can solve the problem that it cannot be used to remove the coarse ceramics, and achieve the effect of unique penetration, moderate cost, and reduction of surface color differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A cleaning agent for ceramics, especially suitable for cleaning zirconia ceramics, its raw materials include the following components in parts by weight: 10 parts of inorganic base, 10 parts of chelating agent, 10 parts of solubilizer, 1 part of anionic surfactant, nonionic 7 parts of surfactant; 62 parts of deionized water.

[0047] The inorganic base is potassium hydroxide with a purity greater than 85%. The electrolytic potassium hydroxide is more difficult to dehydrate than sodium hydroxide after being dissolved in water, and is soluble in ethanol and slightly soluble in ether.

[0048] The chelating agent is hydroxyethylidene diphosphonic acid, a white crystalline, non-toxic, water-soluble important chelating agent with stable structure.

[0049] The solubilizer is diethylene glycol monobutyl ether, which has little odor and is soluble in water and alcohol.

[0050] The anionic surfactant is sodium lauryl sulfate, a white needle-shaped, non-toxic anionic surfactan...

Embodiment 2

[0064] The only difference between this embodiment and Example 1 is: during the preparation method of ceramic cleaning agent: uniformly mix inorganic base, chelating agent, solubilizer, anionic surfactant, nonionic surfactant and deionized water to obtain Ceramic cleaner. The stirring speed is 30 rpm.

[0065] Apply the ceramic cleaning agent obtained in this embodiment to clean the zirconia ceramics according to the same method in Example 1, the effect is:

[0066] The pass rate is above 96%.

[0067] The service life of the cleaning solution is twice that of ordinary ceramic cleaning agents, about 48 hours.

Embodiment 3-5

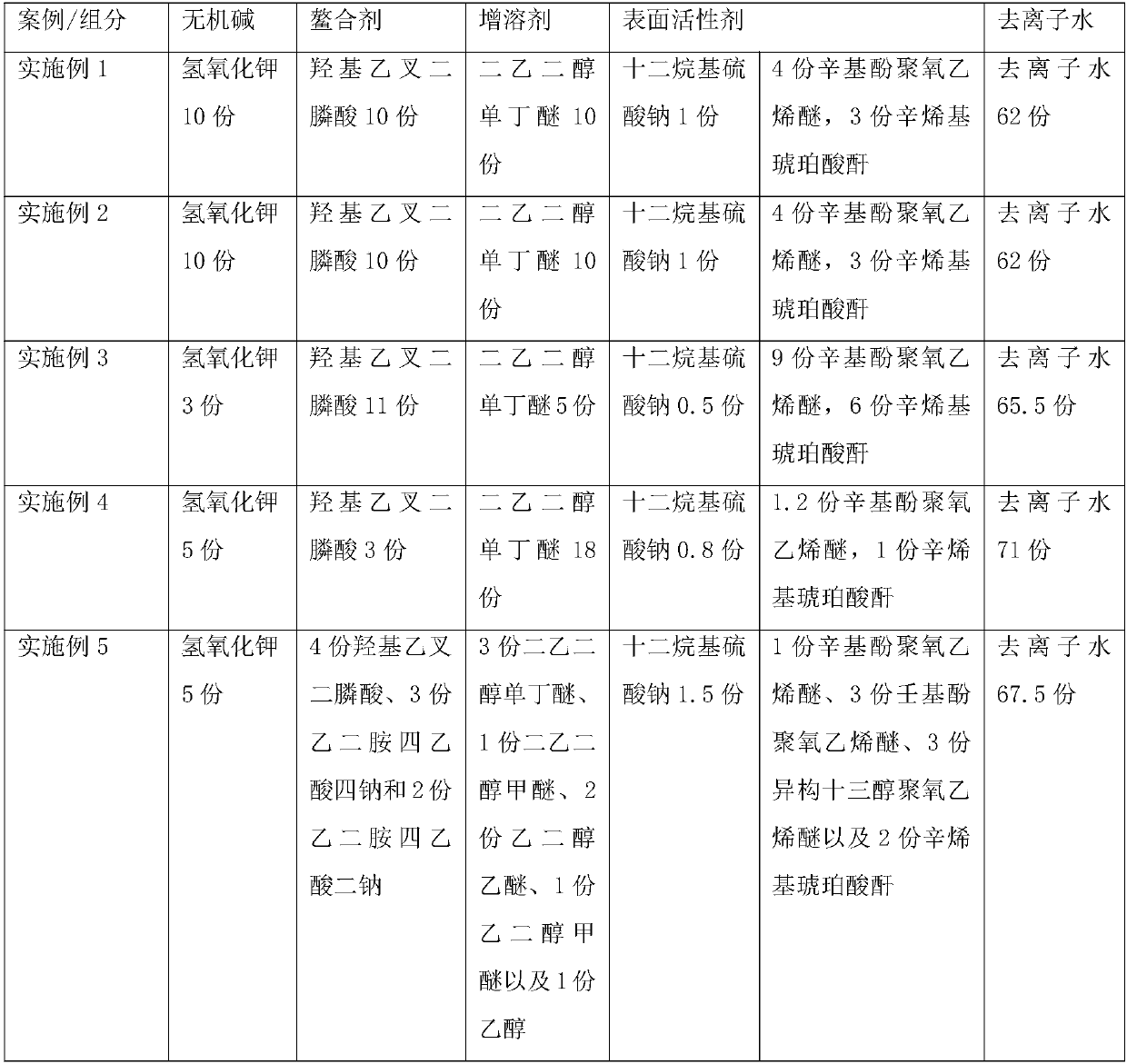

[0069] Embodiment 3-5 differs from embodiment 1 in table 1:

[0070] The component distribution ratio of the ceramic cleaning agent of table 1 embodiment 1-5

[0071]

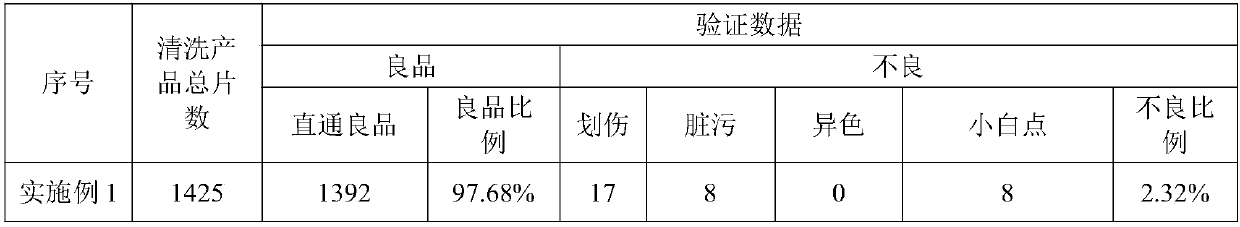

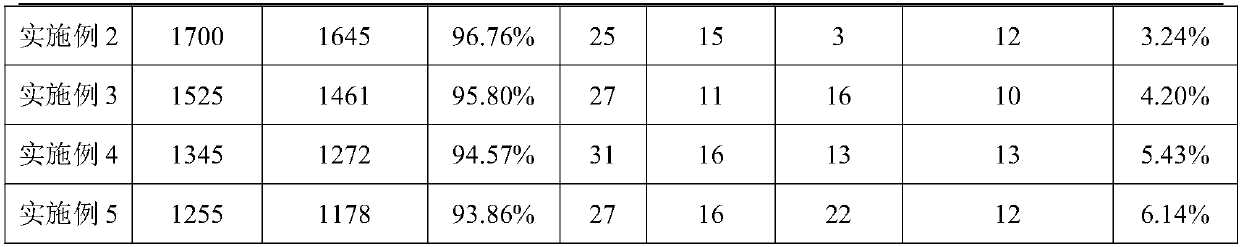

[0072] Table 2 implements the component distribution ratio debugging comparison effect of the ceramic cleaning agent of 1-5:

[0073]

[0074]

[0075] It can be seen from Table 2 that the technical solutions of Examples 3-5 are applied, and the cleaning effect on ceramics is relatively good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com