Rolling type grinding equipment for chemical raw material processing

A chemical raw material, roller press technology, applied in the direction of grain processing, etc., can solve the problems of increased equipment load, slow grinding, and no control of the size of the ground particles, so as to ensure the grinding effect, reduce the load, and grind evenly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

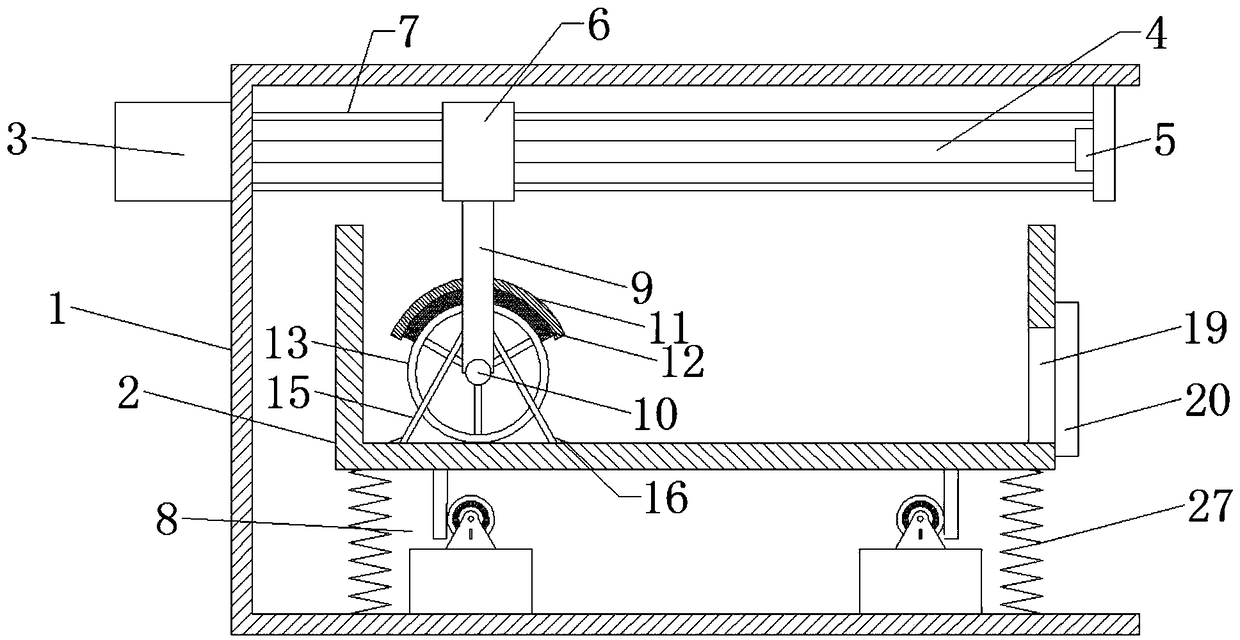

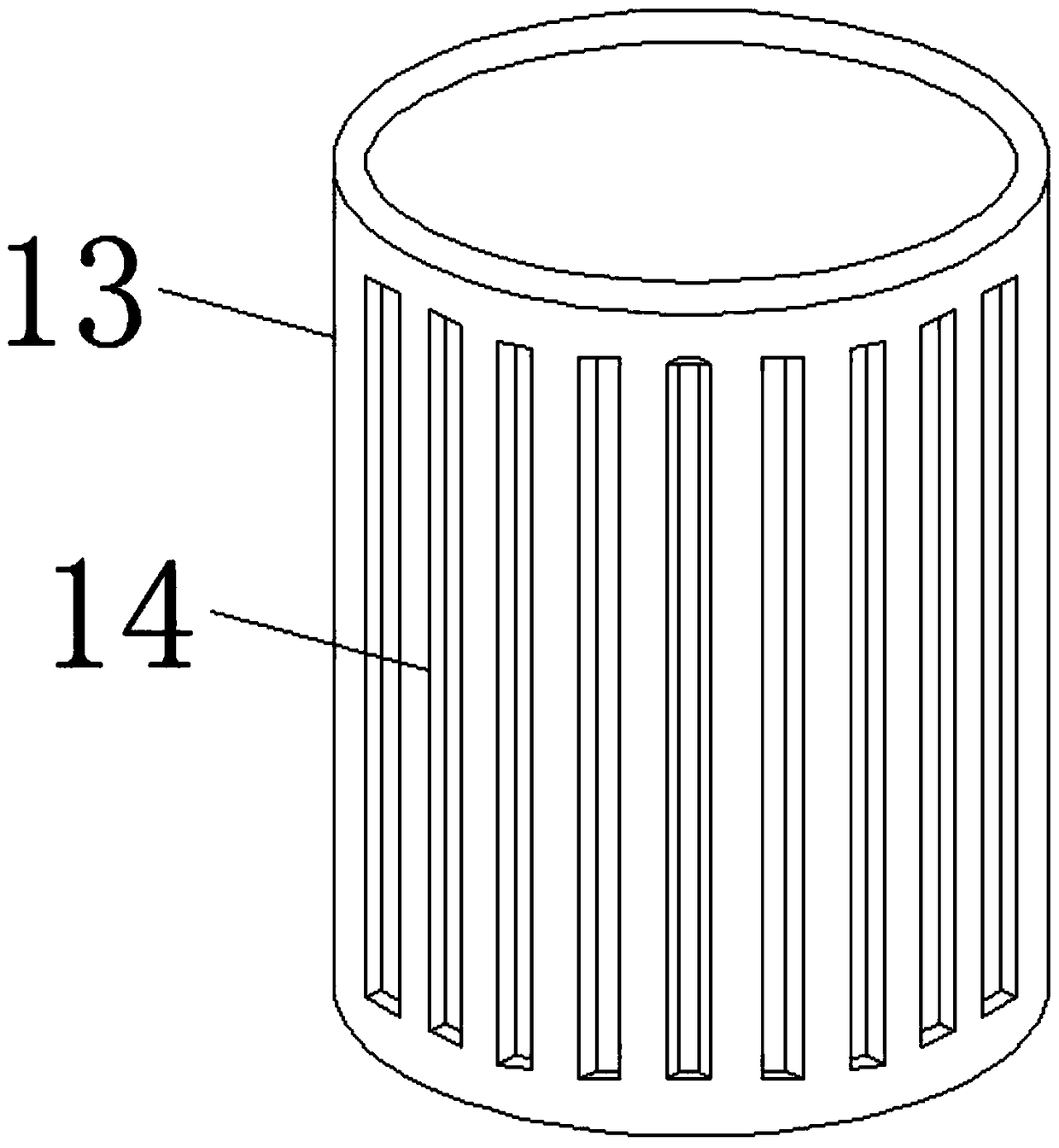

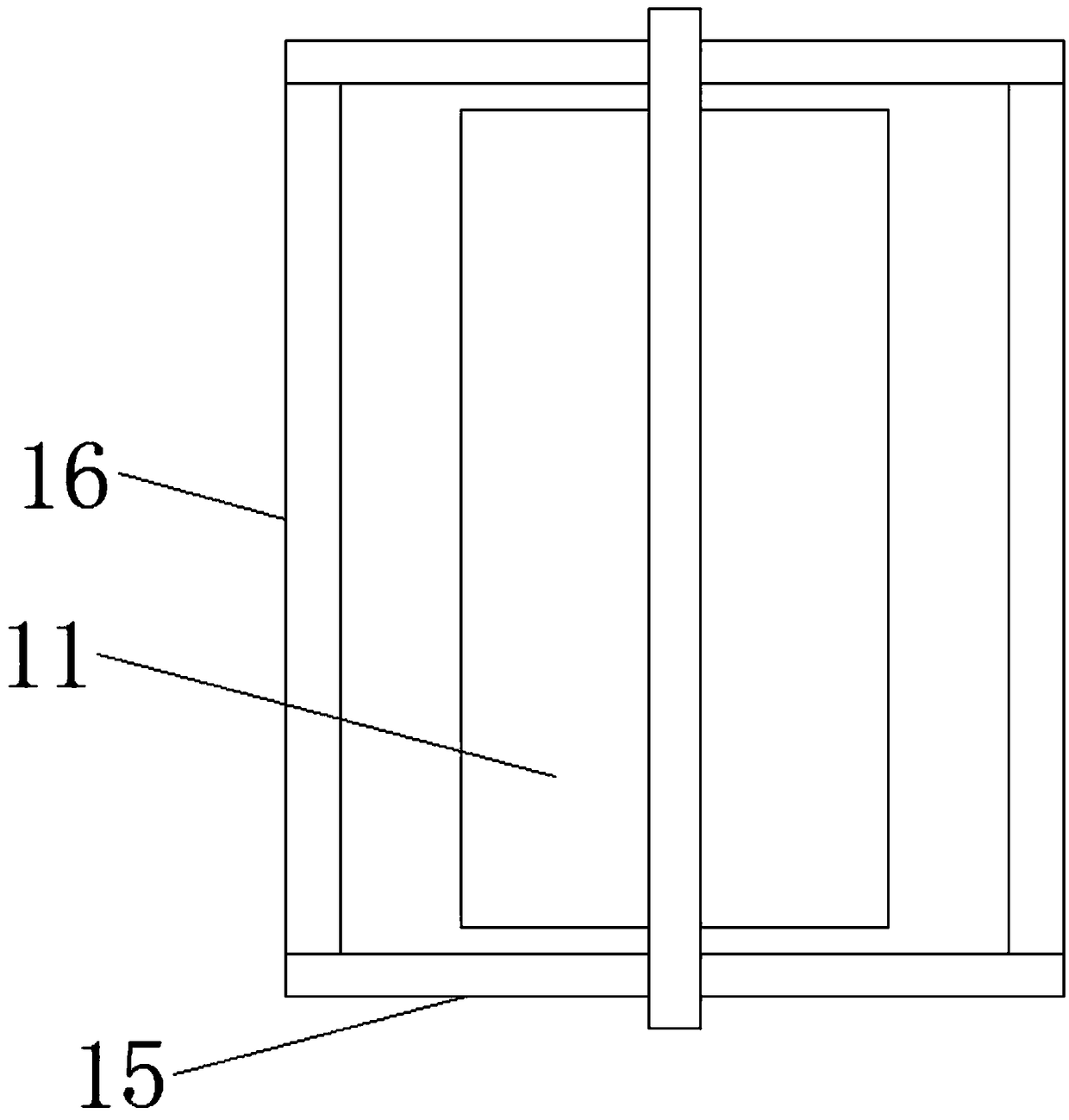

[0017] Please refer to the figure, in the embodiment of the present invention, a kind of rolling grinding equipment for processing chemical raw materials includes a housing 1, a grinding box 2, a motor 3, a screw 4, a bearing 5, a moving seat 6, a guide rod 7 and a support Spring 27; the grinding box 2 is located in the housing 1, and the bottom of the grinding box 2 is supported by several supporting springs 27, which can facilitate the height adjustment of the grinding box 2 while supporting the grinding box 2; the motor 3 is fixedly installed in the housing 1 On the upper end of the side wall, the output shaft of the motor 3 extends horizontally into the housing 1, and a horizontal screw 4 is coaxially fixed on the output shaft of the motor 3, and the other end of the screw 4 is rotationally connected with the fixed bearing 5. On the side wall of the housing 1, the screw rod 4 is driven to rotate by the motor 3; the screw rod 4 is threaded through the moving seat 6, and a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com