Wrench

A wrench and shaft technology, applied in the field of wrenches, can solve the problems of narrow use range, labor-intensive, unable to cover bolt removal work, etc., and achieve the effect of improving practicability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

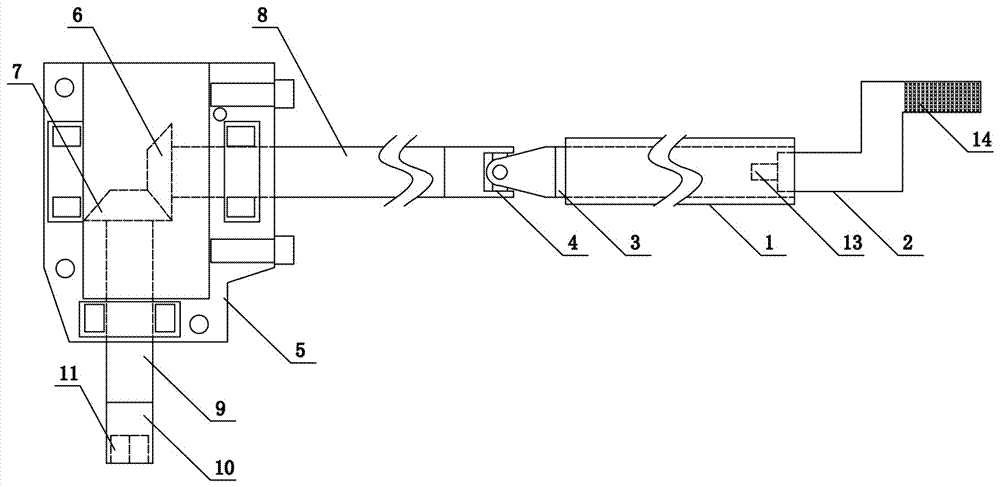

[0031] like figure 1 As shown, the present invention includes a first connecting rod 1, a steering mechanism and an operating handle 2. The outer wall of the operating handle is provided with X-shaped anti-slip lines 14. The first connecting rod 1 is a hollow tube and is rotatably connected to the first rotating shaft 3. The operating handle 2 is plugged with the right end of the first rotating shaft 3, and the specific implementation method can be matched with the plug-in block 13 and the socket that cooperate with each other. The left end of the first rotating shaft 3 extends out of the first connecting rod 1 and is fixedly installed with the universal joint 4. The universal joint 4 adopts a cross-shaft rigid universal joint. The steering mechanism includes a housing 5 and a first bevel gear 6 and a second bevel gear 7 arranged in the housing 5. The first bevel gear 6 coaxially fixes the second rotating shaft 8. The right end of the second rotating shaft 8 extends out of the...

Embodiment 2

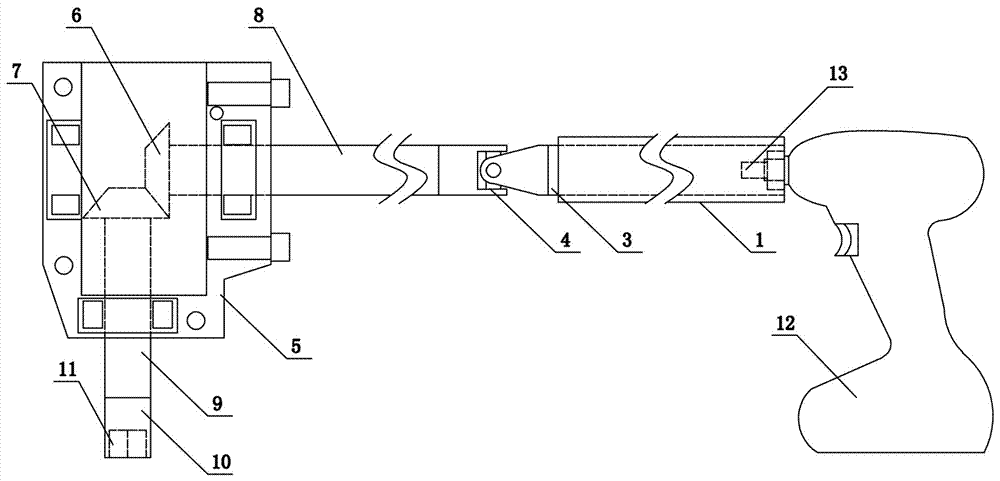

[0034] like figure 2 As shown, the present invention includes a first connecting rod 1, a steering mechanism and a motor 12. The motor 12 adopts a hand-held motor with a forward and reverse switch in the prior art that can rotate in both forward and reverse directions. The first connecting rod 1 is a hollow tube and its The first rotating shaft 3 is connected by internal rotation, and the operating handle 2 is inserted into the right end of the first rotating shaft 3. The specific implementation method can be matched with the plug-in block 13 and the jack, and the left end of the first rotating shaft 3 protrudes from the first connecting rod. 1. The universal joint 4 is installed externally and fixedly. The universal joint 4 adopts a cross-shaft rigid universal joint. The steering mechanism includes a casing 5 and a first bevel gear 6 and a second bevel gear 7 arranged in the casing 5. The first bevel The gear 6 coaxially fixes the second rotating shaft 8, and the right end o...

Embodiment 3

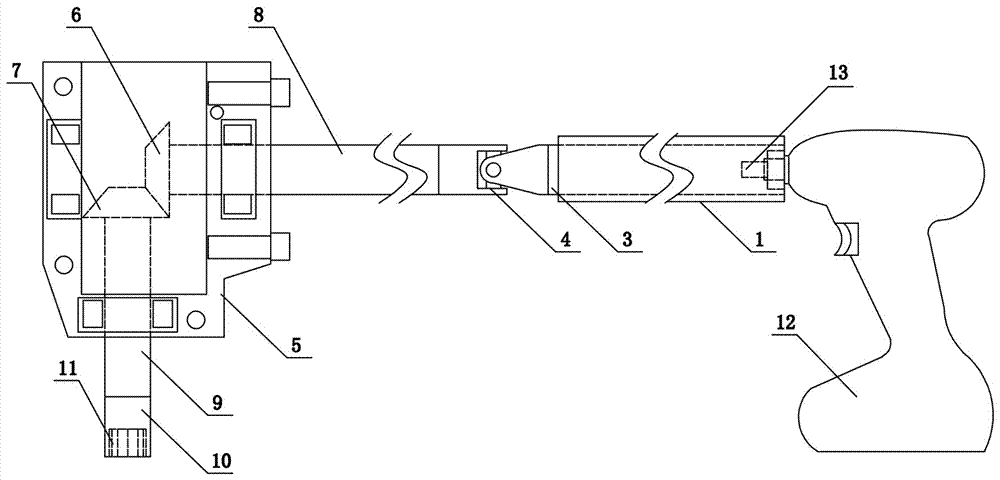

[0037] like image 3 As shown, the present invention includes a first connecting rod 1, a steering mechanism and a motor 12. The motor 12 adopts a hand-held motor with a forward and reverse switch in the prior art that can rotate in both forward and reverse directions. The first connecting rod 1 is a hollow tube and its The first rotating shaft 3 is connected by internal rotation, and the operating handle 2 is inserted into the right end of the first rotating shaft 3. The specific implementation method can be matched with the plug-in block 13 and the jack, and the left end of the first rotating shaft 3 protrudes from the first connecting rod. 1. The universal joint 4 is installed externally and fixedly. The universal joint 4 adopts a cross-shaft rigid universal joint. The steering mechanism includes a casing 5 and a first bevel gear 6 and a second bevel gear 7 arranged in the casing 5. The first bevel The gear 6 coaxially fixes the second rotating shaft 8, and the right end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com