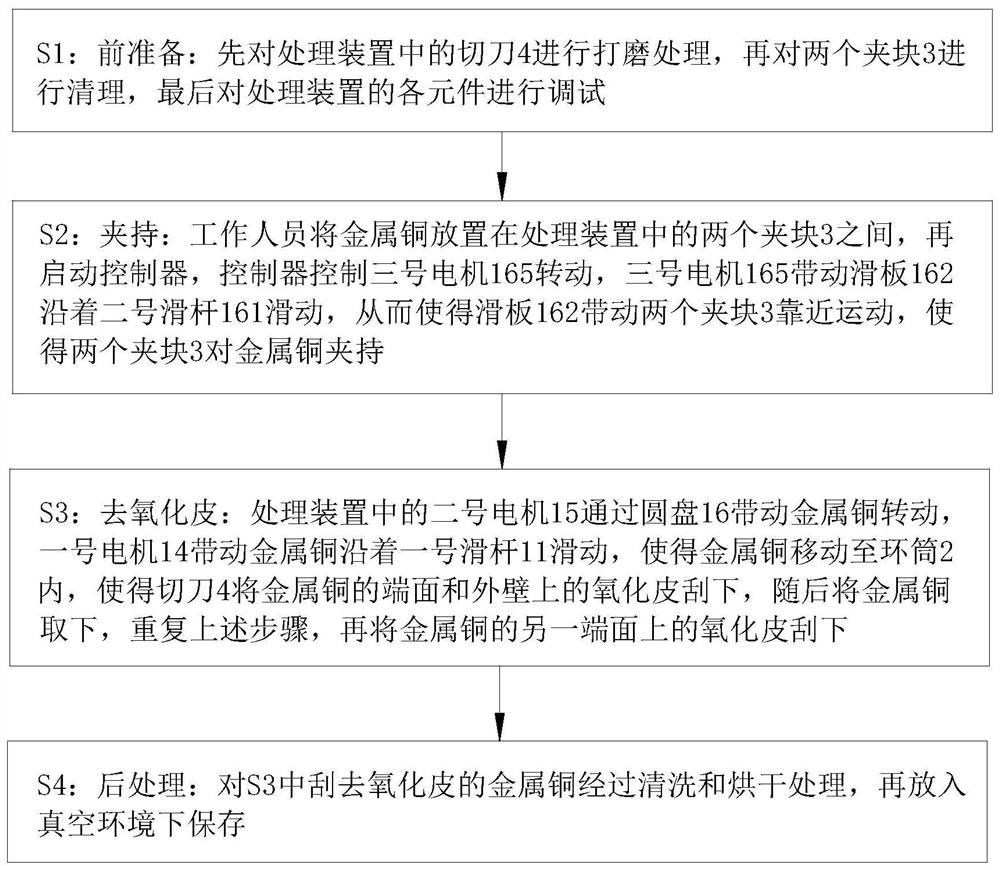

Metal copper surface oxide skin treatment process

A surface oxidation and treatment technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problem of incomplete removal of oxide scale on metal copper surface, difficult processing and use, and poor cleaning of local contact surfaces of parts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

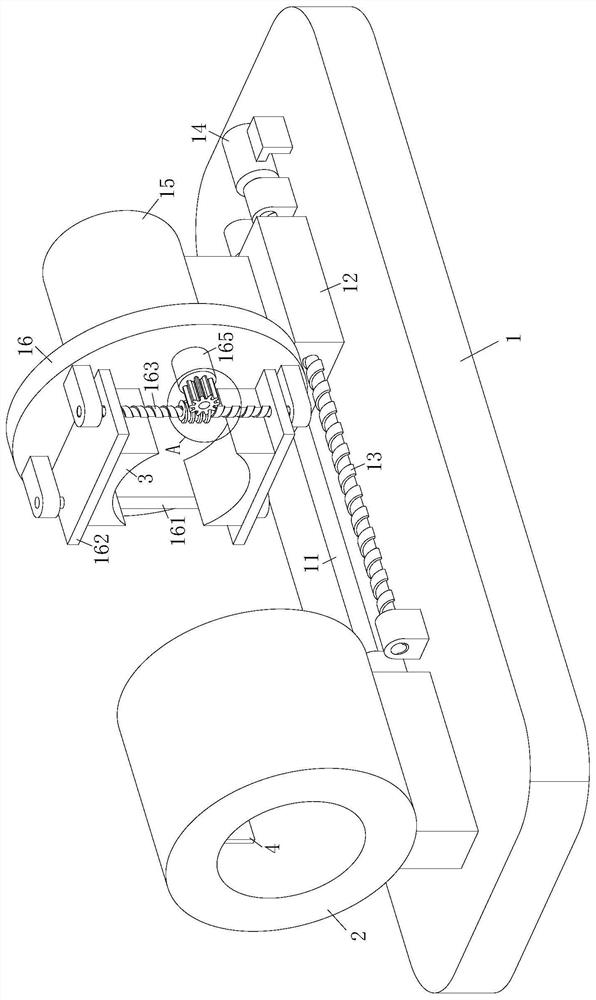

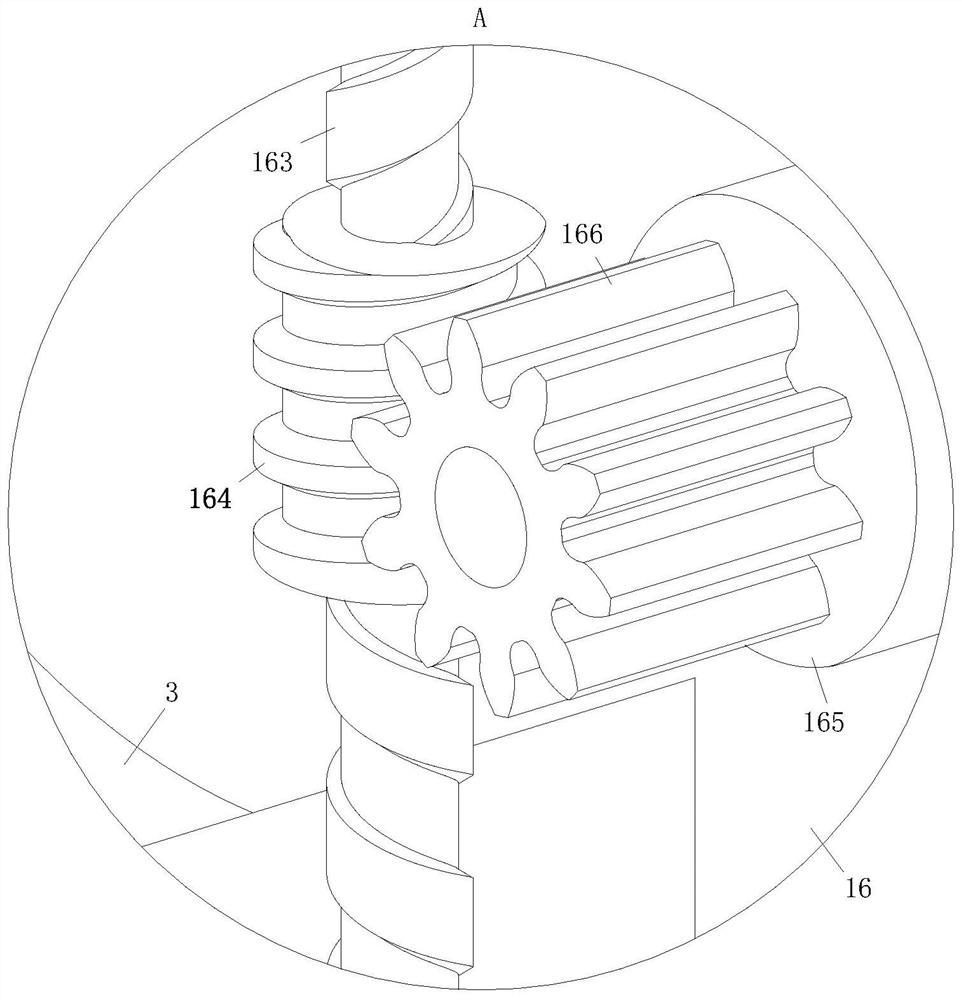

[0046] As an embodiment of the present invention, the inner wall of the ring cylinder 2 is provided with a rectangular groove 22; the rectangular groove 22 and the strip groove 21 are evenly distributed on the inner wall of the ring cylinder 2, and the rectangular groove 22 is slidingly connected Resist plate 23, also be provided with No. 2 spring 221 in rectangular groove 22; The elastic force of described No. 2 spring 221 and No. 1 spring 211 is the same, one end of No. 2 spring 221 is connected with the groove bottom of rectangular groove 22, and the other end is connected with Abutment plate 23; the edge of said abutment plate 23 is rotatably connected to a roller 24; the axis of said roller 24 is parallel to the axis of ring cylinder 2; when in use, the process of scraping off the scale on the outer surface of copper rod by cutter 4 Among them, the copper rod is always pressed against the cutter 4 by the No. 1 spring 211. Due to the physical characteristics of copper, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com