Preparation method of long-acting photocatalytic self-cleaning fabric

A self-cleaning, fabric technology, applied in physical treatment, textiles and papermaking, fiber treatment, etc., can solve the problem of poor bonding fastness between inorganic photocatalytic particles and cotton fibers, decreased contact between photocatalyst and air and light, and difficult to fix fibers Fabric surface and other problems, to achieve good photocatalytic performance and hydrophilic performance, excellent thermal stability, efficient self-cleaning and antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a long-acting nano-photocatalytic self-cleaning fabric, the specific steps are:

[0028] A 10×10 cm 50 / 50 cotton-polyester fabric was washed with non-ionic detergent 3% (owf) Sandoclean PC at 30°C for 30 minutes, then ultrasonically treated in ethanol and deionized water for 0.5 hours, and dried at room temperature.

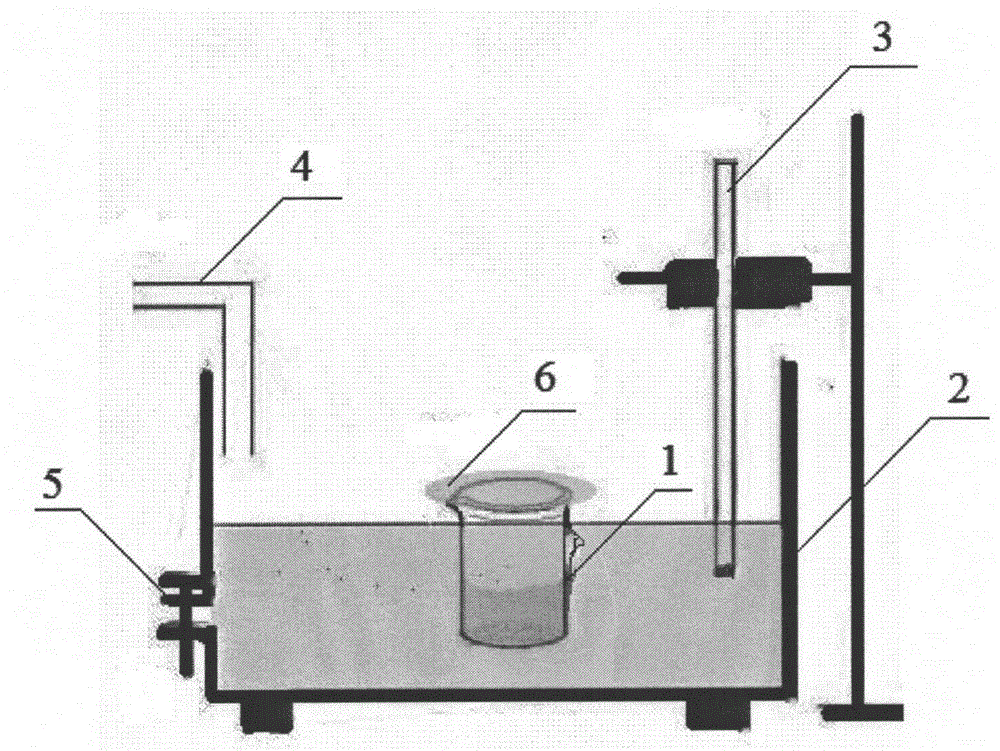

[0029] Such as figure 1 As shown, mix 0.4ml of HCl solution with a mass fraction of 37% and 100ml of deionized water, the pH of the resulting mixed solution is 2-3, place the mixed solution in beaker 1, and stir at a speed of 600 rpm at room temperature For 5 minutes, the fabric was immersed in the mixed solution, and the beaker 1 was covered with plastic wrap 6 and then placed in the ultrasonic device 2 filled with water. Ultrasound was performed at room temperature for 5 minutes, and the ultrasonic state was maintained. Add 2 drops / 9 ml of isopropyl titanate solution with a mass fraction of 99% was added dropwise at a speed of 2...

Embodiment 2

[0033] A preparation method of a long-acting nano-photocatalytic self-cleaning fabric, the specific steps are:

[0034] A 10×10 cm 35 / 65 cotton-polyester fabric was washed with non-ionic detergent 3% (owf) Sandoclean PC at 40°C for 20 minutes, then ultrasonically treated in ethanol and deionized water for 0.5 hours, and dried at room temperature.

[0035] Such as figure 1As shown, 0.2ml mass fraction of 37% HCl and 100ml deionized water are mixed, the pH of the resulting mixed solution is 3-4, the mixed solution is placed in beaker 1, and the stirring speed is 500 rpm at room temperature Stir for 10 minutes. Immerse the fabric in the mixed solution, cover the beaker 1 with plastic wrap 6 and place it in the ultrasonic device 2 filled with water, ultrasonicate for 8 minutes at room temperature, keep the ultrasonic state, and drop into the mixed solution at a rate of 2 drops / second Add 10 ml of isopropyl titanate solution with a mass fraction of 99%, raise the temperature to 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com