Sodium chloride and sodium sulfate mixed waste salt resource reutilization method

A sodium sulfate and sodium chloride technology, applied in chemical instruments and methods, alkali metal sulfite/sulfate purification, alkali metal sulfite/sulfate dehydration, etc., can solve large water consumption and high energy consumption , dealing with difficult issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

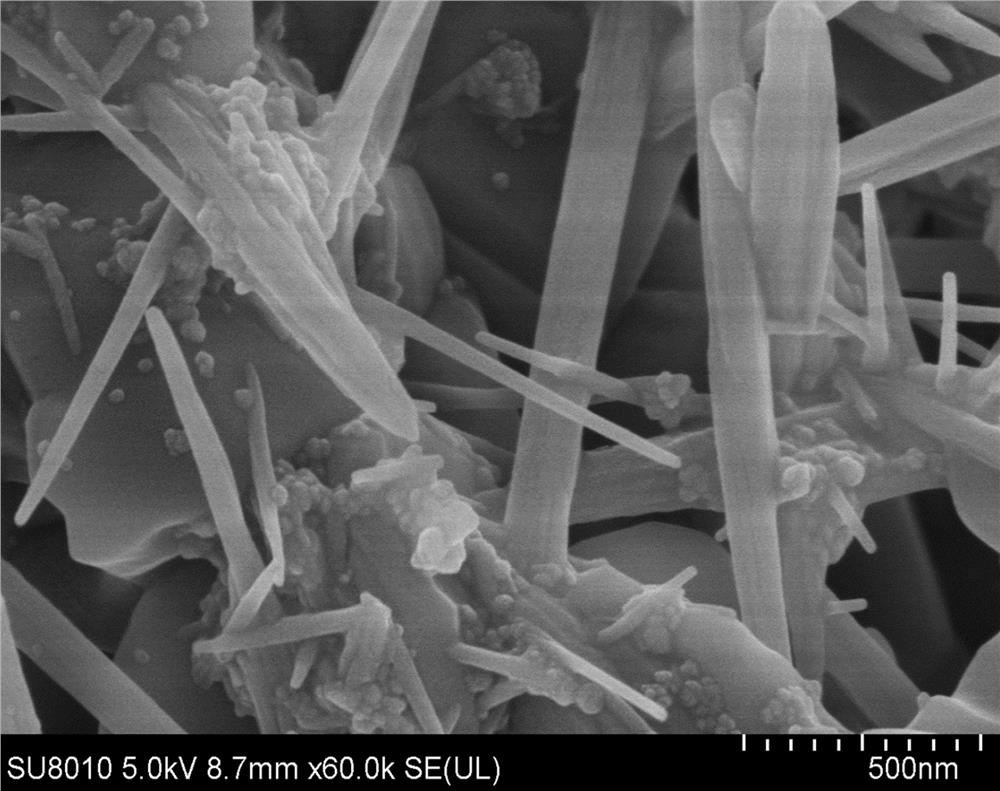

Image

Examples

Embodiment 1

[0028] A method for resource recycling of sodium chloride and sodium sulfate mixed waste salt, the scheme of which is:

[0029] Step 1. Co-processing: Mix 50kg of mixed waste salt with 0.1kg of cracking aid to obtain the mixed material, and send the mixed material into the pyrolysis equipment. The pyrolysis equipment is equipped with a heating layer and a material chamber, and the heating layer Connected with the cement kiln decomposition system, the heat of the cement kiln is introduced into the pyrolysis equipment to heat the mixed waste salt in the material room, firstly at 320°C for 20 minutes, then heated to 850°C, and the reaction time is 30 minutes; The material chamber is in the anaerobic heating state, and the flue gas and air produced by the organic matter are mixed according to the volume ratio of 0.8:0.8 and enter the cement kiln decomposition furnace through the pipeline, and enter the cement kiln waste gas system after being fully burned;

[0030] Step 2. Dissolu...

Embodiment 2

[0041] A method for resource recycling of sodium chloride and sodium sulfate mixed waste salt, the scheme of which is:

[0042] Step 1. Co-processing: mix 65kg of mixed waste salt with 0.3kg of cracking aid to obtain the mixed material, and send the mixed material into the pyrolysis equipment. The pyrolysis equipment is equipped with a heating layer and a material chamber, and the heating layer Connected with the cement kiln decomposition system, the heat of the cement kiln is introduced into the pyrolysis equipment to heat the mixed waste salt in the material room, firstly at 380°C for 30 minutes, then heated to 950°C, and the reaction time is 45 minutes; The material chamber is in the anaerobic heating state, and the flue gas and air produced by the organic matter are mixed according to the volume ratio of 0.8:0.95 and enter the cement kiln decomposition furnace through the pipeline, and enter the cement kiln waste gas system after full combustion;

[0043] Step 2. Dissoluti...

Embodiment 3

[0054] A method for resource recycling of sodium chloride and sodium sulfate mixed waste salt, the scheme of which is:

[0055] Step 1. Co-processing: mix 80kg of mixed waste salt with 0.6kg of cracking aid to obtain the mixed material, and send the mixed material into the pyrolysis equipment. The pyrolysis equipment is equipped with a heating layer and a material chamber, and the heating layer Connected with the cement kiln decomposition system, the heat of the cement kiln is introduced into the pyrolysis equipment to heat the mixed waste salt in the material room, firstly at 480°C for 40min, then heated to 1000°C, and the reaction time is 60min; The material chamber is in the anaerobic heating state, and the flue gas and air produced by the organic matter are mixed according to the volume ratio of 0.8:1.1 and enter the cement kiln decomposition furnace through the pipeline, and enter the cement kiln waste gas system after full combustion;

[0056] Step 2, dissolving treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com