Beneficiation method for recovering ultra-low-grade rare earth and fluorite from rare earth tailings

A technology of rare earth tailings and fluorite, which is applied in recycling technology, mechanical material recovery, solid separation, etc., can solve problems such as reducing operating costs, reducing tailings discharge, and increasing corporate benefits, so as to reduce operating costs and reduce tailings. Mine emissions, increase the effect of corporate benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

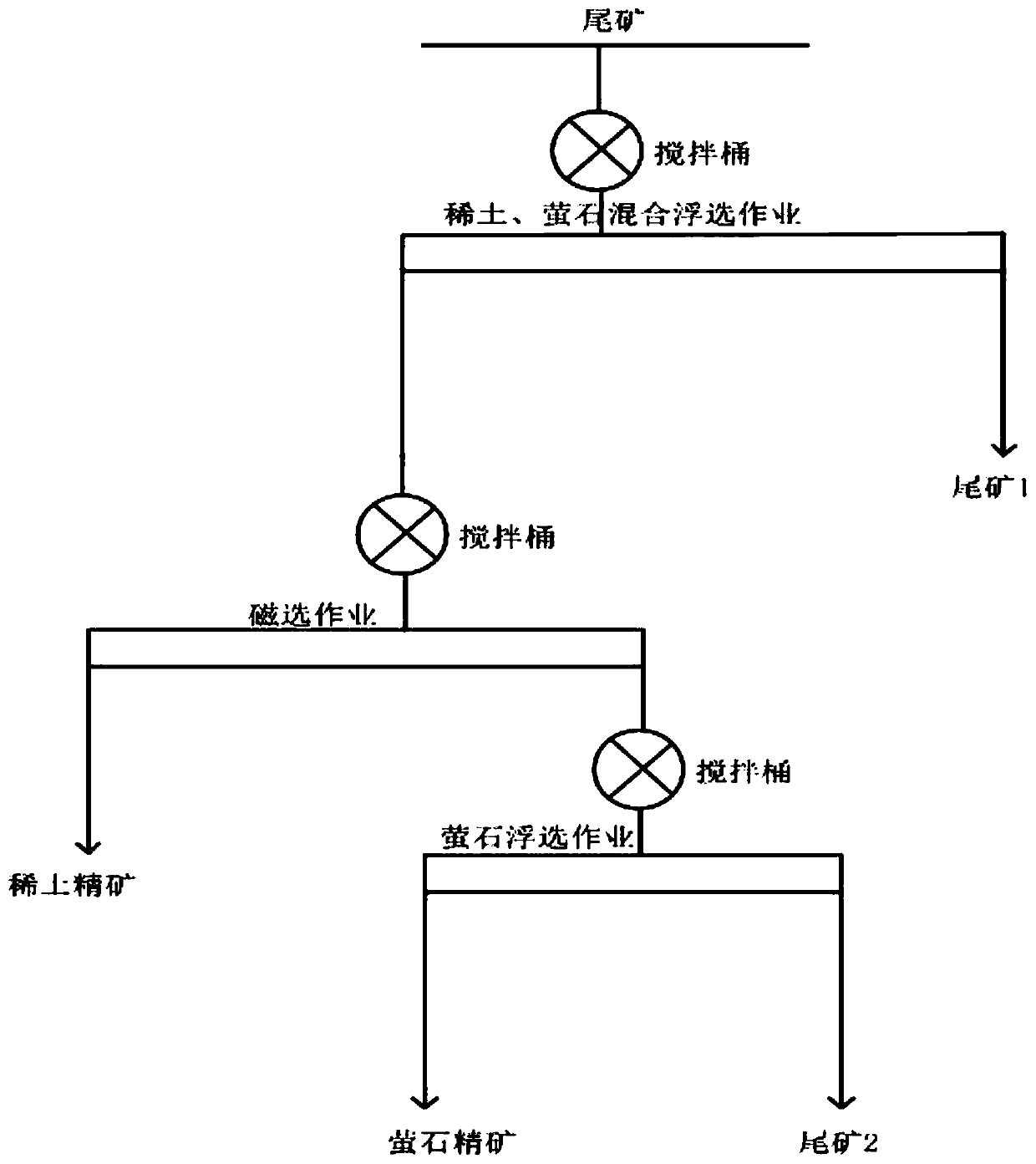

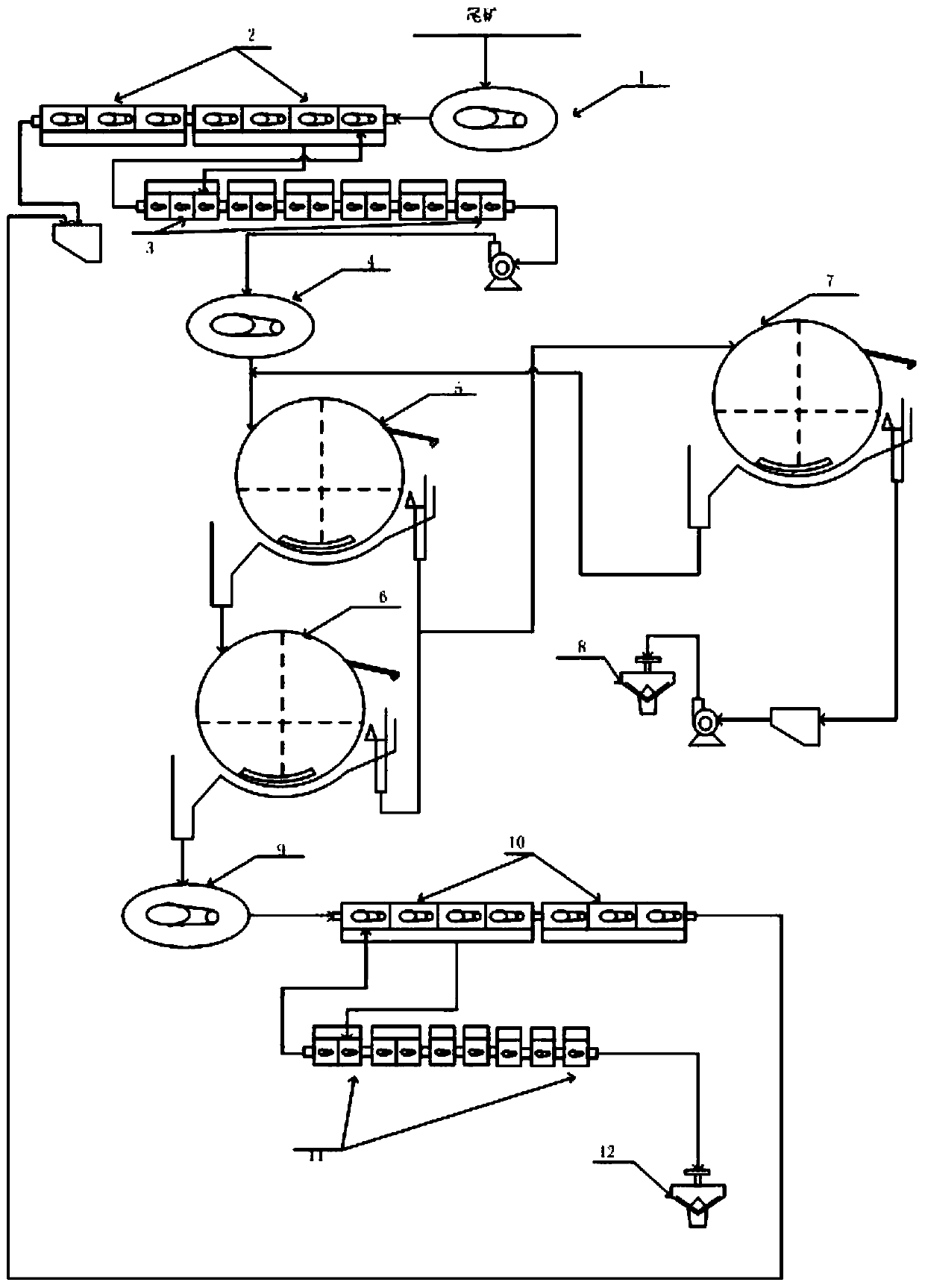

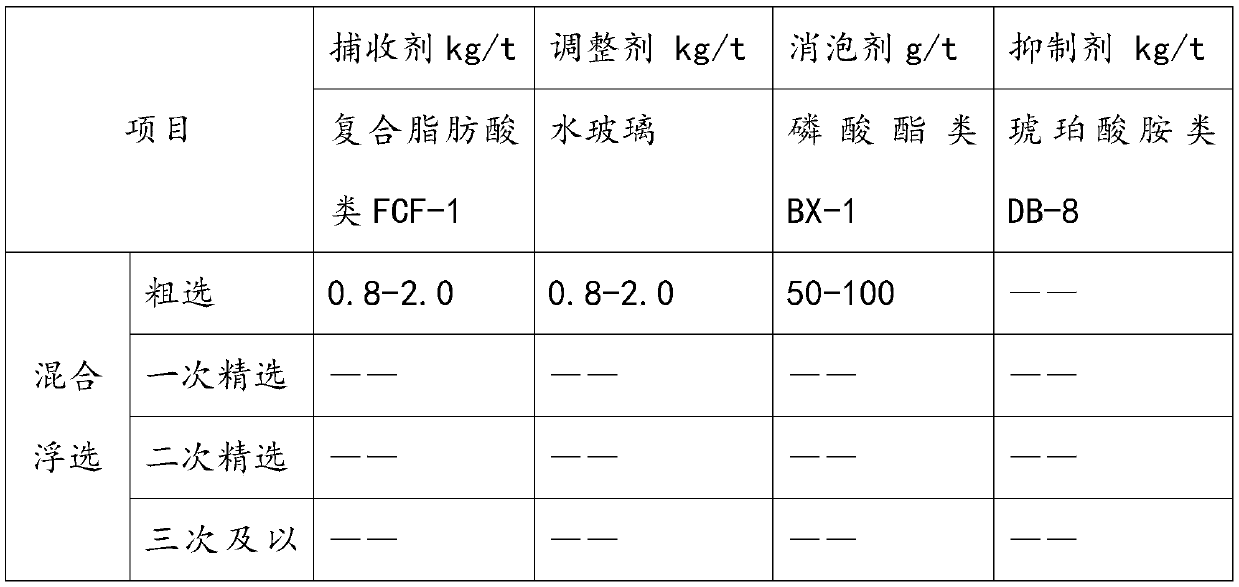

[0054] Taking a bastnaesite in Sichuan Province as an example, after the rare earth beneficiation process and sorting, the rare earth tailings left contain rare earth, fluorite, barite, quartz, carbonate and other gangues, and the rare earth content is only Below 1%, the fluorite content is only 2%-5%, and the mud content is high, and the composition is complex. Compared with other fluorite mines, the grade is only 1 / 10. figure 2 It is a schematic diagram of the equipment connection of the rare earth fluorite combined beneficiation method. In the figure, the number of equipment and processes are for illustration purposes only, and do not represent the actual number of equipment and processes.

[0055] Such as figure 2 As shown, the rare earth tailings are stirred and mixed by the mixing tank 1 and then flow into the mixed rougher flotation unit 2. After the mixed rougher flotation unit is operated, the mixed rougher flotation tailings flow into the pump pool by themselves, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com