Dry-method flue gas purification method and dry-method flue gas purification device of simultaneously desulfurizing, denitrating and removing mercury

A technology for desulfurization, denitrification, mercury removal, and flue gas purification. It is applied in chemical instruments and methods, separation methods, and air quality improvement. It can solve problems such as high process operation requirements, high purification costs, and secondary pollution, and simplify the process flow. and system structure, reducing investment and operating costs, and reducing the effect of equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

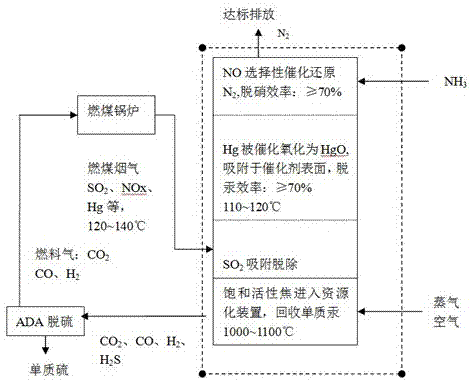

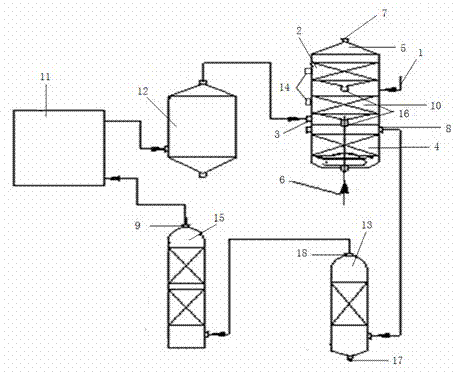

[0043] The simultaneous desulfurization, denitrification and demercuration dry flue gas purification method described in this embodiment includes the following steps, such as figure 1 Shown:

[0044] (1) Remove SO from the flue gas after electrostatic precipitating under the action of coal-based activated carbon 2 , wherein the reaction temperature is 120°C, and the reaction time is 24 hours;

[0045] (2) Pass the flue gas treated in step (1) into the device equipped with coal-based activated carbon, and at the same time pass NH 3 , the reaction temperature is 110°C, the reaction time is 24 hours, Hg 0 Catalytic oxidation to HgO, NOx is selectively catalytically reduced to N 2 ;

[0046] (3) Pass the coal-based activated carbon that has absorbed flue gas in steps (1) and (2) into the resource treatment area, and generate CO and H under the action of air and steam. 2 、H 2 S, the volume ratio of air and water vapor is 5:1, the reaction temperature is 1000°C, and the reacti...

Embodiment 2

[0051] The simultaneous desulfurization, denitrification and demercuration dry flue gas purification method described in this embodiment comprises the following steps

[0052] (1) Remove SO from the flue gas after electrostatic precipitating under the action of coal-based activated carbon 2 , wherein the reaction temperature is 130°C, and the reaction time is 30 hours;

[0053] (2) Pass the flue gas treated in step (1) into the device equipped with coal-based activated carbon, and at the same time pass NH 3 , the reaction temperature is 115°C, the reaction time is 35 hours, Hg 0 Catalytic oxidation to HgO, NOx is selectively catalytically reduced to N 2 ;

[0054] (3) Pass the coal-based activated carbon that has absorbed flue gas in steps (1) and (2) into the resource treatment area, and generate CO and H under the action of air and steam. 2 、H 2 S, the volume ratio of air and water vapor is 7:1, the reaction temperature is 1050°C, and the reaction time is 30 hours.

[...

Embodiment 3

[0059] The simultaneous desulfurization, denitrification and demercuration dry flue gas purification method described in this embodiment comprises the following steps

[0060] (1) Remove SO from the flue gas after electrostatic precipitating under the action of coal-based activated carbon 2 , wherein the reaction temperature is 140°C, and the reaction time is 48 hours;

[0061] (2) Pass the flue gas treated in step (1) into the device equipped with coal-based activated carbon, and at the same time pass NH 3 , the reaction temperature is 120°C, the reaction time is 48 hours, Hg 0 Catalytic oxidation to HgO, NOx is selectively catalytically reduced to N 2 ;

[0062] (3) Pass the coal-based activated carbon that has absorbed flue gas in steps (1) and (2) into the resource treatment area, and generate CO and H under the action of air and steam. 2 、H 2 S, the volume ratio of air and water vapor is 10:1, the reaction temperature is 1100°C, and the reaction time is 48 hours.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com