Resource utilization method of waste residues generated by 1-nitroanthraquinone production by solvent method

A technology of nitroanthraquinone and dinitroanthraquinone is applied in the field of resource utilization of waste residue produced by solvent production of 1-nitroanthraquinone, and can solve the problem of small application value of dyes, no industrial value, poor dye performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

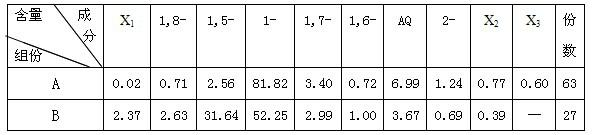

[0020] Crush 200kg of "waste residue" and 2000kg of water together, add 140kg of sodium sulfite, heat to 96-100°C for 2 hours; cool down to 85°C, filter, wash the filter cake with hot water at 80°C until the filtrate is colorless, dry the filter cake, and mix Nitrate 90kg. Put the dried mixed nitric acid into 1000L of toluene, heat to 105-110°C, keep it warm for about 1 hour, and filter while it is hot. The filter cake is component B, wash off the toluene with methanol, and dry; add water to the toluene filtrate, remove the toluene by steam distillation, filter out component A, and dry. The result is as follows:

[0021]

[0022] In the table: X 1 , x 2 、X 3 for the unknown

[0023] 1,8- that is, 1,8-dinitroanthraquinone;

[0024] 1,5- that is, 1,5-dinitroanthraquinone;

[0025] 1- is 1-nitroanthraquinone;

[0026] 1,7- that is, 1,7-dinitroanthraquinone;

[0027] 1.6- namely 1,6-dinitroanthraquinone;

[0028] AQ is ant...

Embodiment 2

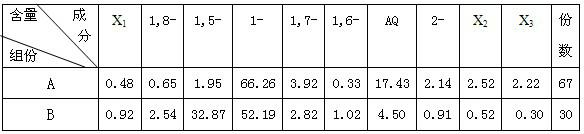

[0031] 200kg of "waste residue", add 1600kg of water to pulverize together, add 100kg of sodium sulfite, heat to 92-96°C for 5 hours; cool down to 85°C for filtration, wash the filter cake with hot water at 80°C until the filtrate is colorless, dry the filter cake, and obtain mixed Nitrate 100kg. Put the dried mixed nitrate into 1500L mixed xylene, heat it to 115-120°C, keep it warm for about 1 hour, and filter it while it is hot. The following operations are the same as in Example 1. The result is as follows:

[0032]

Embodiment 3

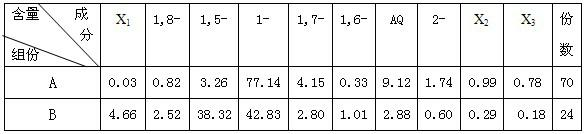

[0034] 200 kg of "waste residue", crushed together with 800 kg of water, and ammonium bisulfite solution obtained by absorbing sulfur dioxide with ammonia water, converted to 100% NH 4 HSO 3 60 kg, add 15% ammonia water to make the solution pH 7~8, heat up to 100~105°C and react for 4 hours; cool down to 85°C and filter, wash with hot water at 80°C until the filtrate is colorless, dry the filter cake to obtain mixed nitric acid 110 kg. Put the dry mixed nitric acid into 1200L o-xylene, heat to 130-135°C, keep it warm for about 1 hour, and filter while it is hot. The following operations are the same as in Example 1. The result is as follows:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com