Asphalt antistripping agent

An anti-stripping agent and asphalt technology, which is applied in the field of asphalt anti-stripping agent preparation, can solve problems such as easy aging, asphalt peeling, and asphalt wax content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Embodiment 1: 45Kg of nano-calcium carbonate and 55Kg of yttrium chloride powder are mixed at room temperature and then stirred evenly to obtain an asphalt anti-stripping agent.

Embodiment 2

[0008] Mix 50Kg of nano-calcium carbonate and 50Kg of yttrium chloride powder at room temperature and stir evenly to obtain the asphalt anti-stripping agent.

Embodiment 3

[0010] Mix 55Kg of nano-calcium carbonate and 45Kg of yttrium chloride powder at room temperature and stir evenly to obtain an asphalt anti-stripping agent.

[0011] When the asphalt anti-stripping agent is used, the addition amount is 0.5-1% by weight of the asphalt.

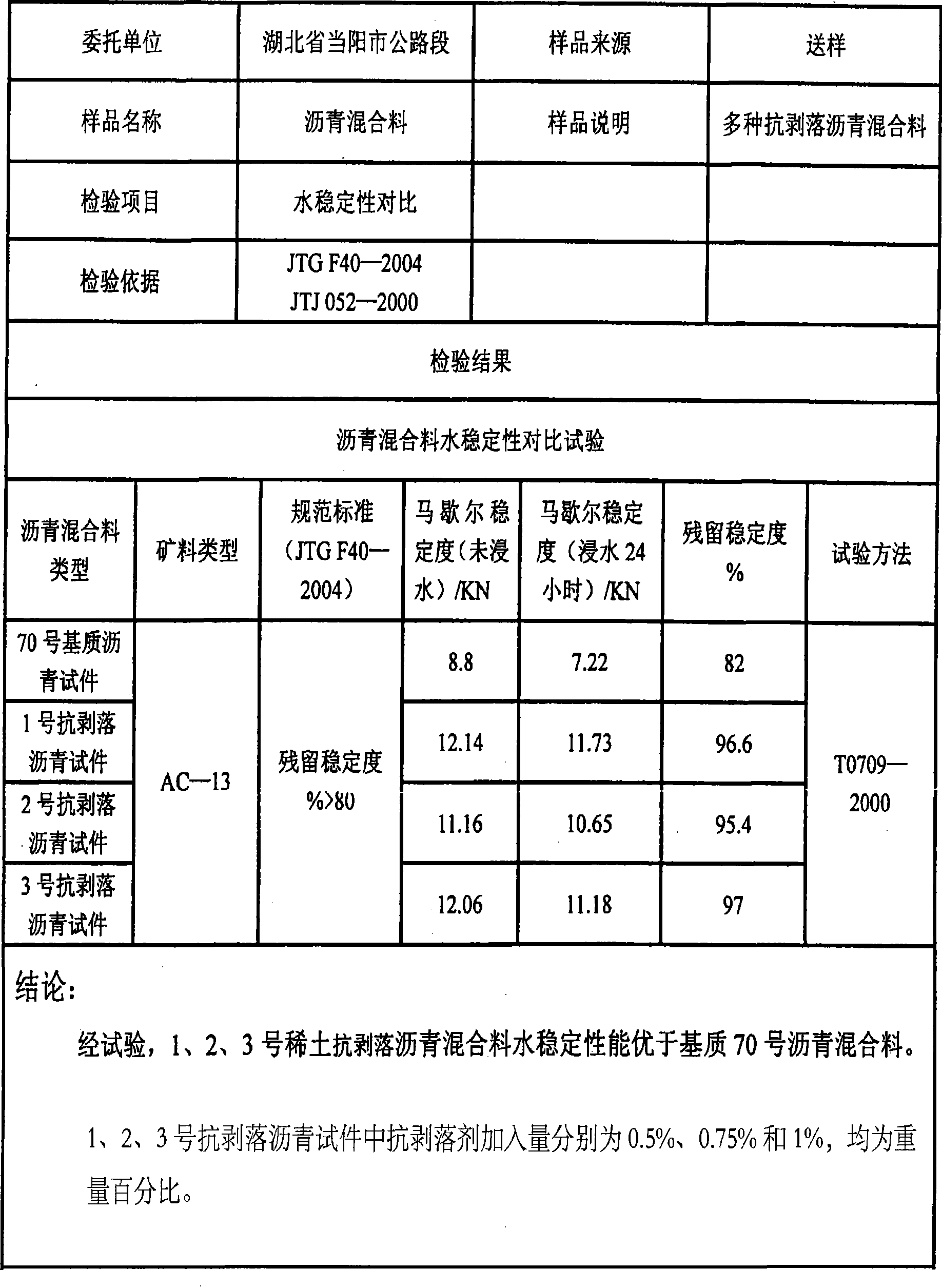

[0012] The water stability test report of the asphalt mixture added with this asphalt anti-stripping agent is shown in Table 1:

[0013] Experiment report on water stability performance of asphalt mixture Table 1

[0014]

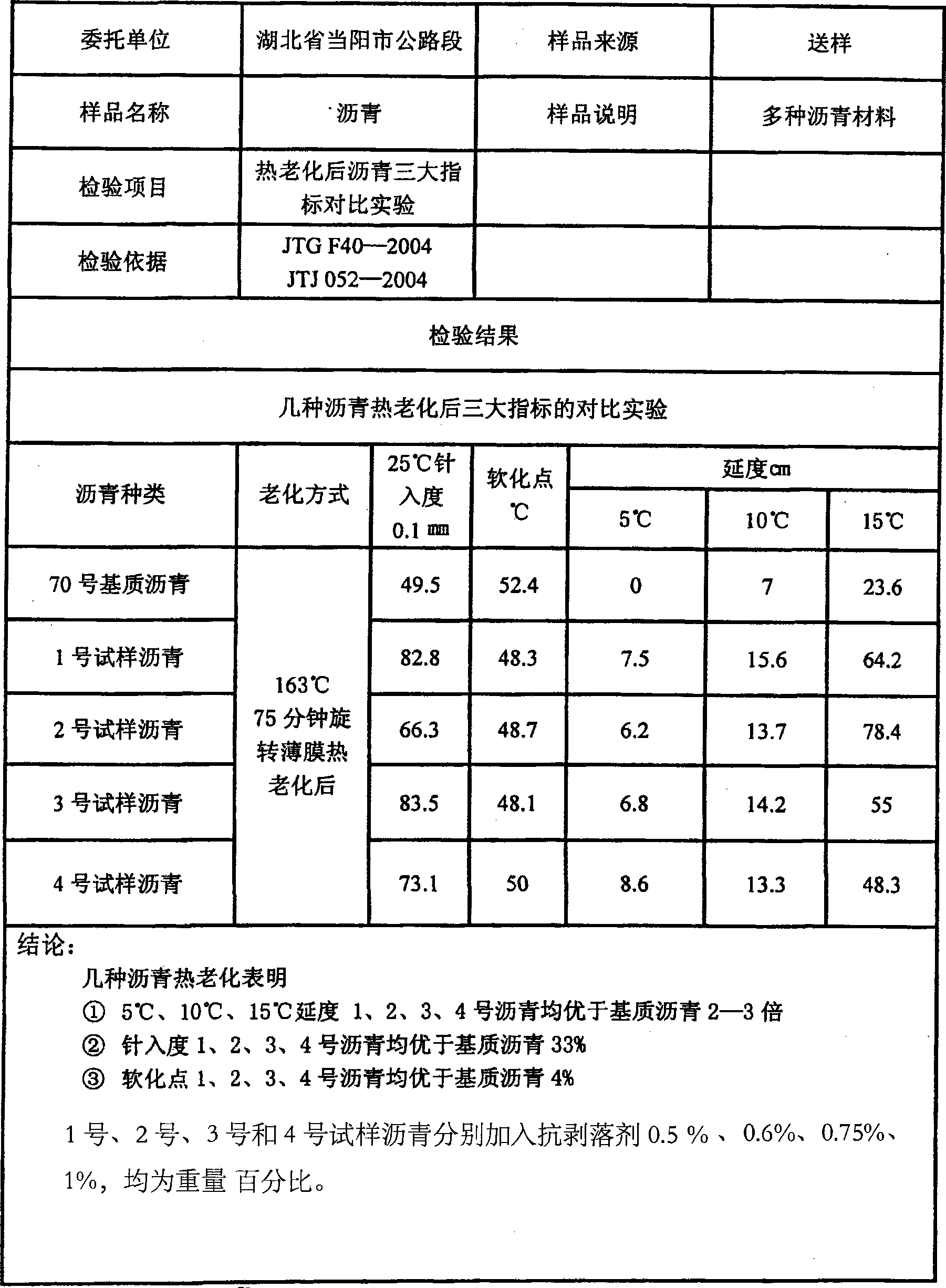

[0015] Table 2 of the anti-aging performance test report of asphalt materials added with this asphalt anti-stripping agent:

[0016] Experimental report on thermal aging resistance of asphalt materials Table 2

[0017]

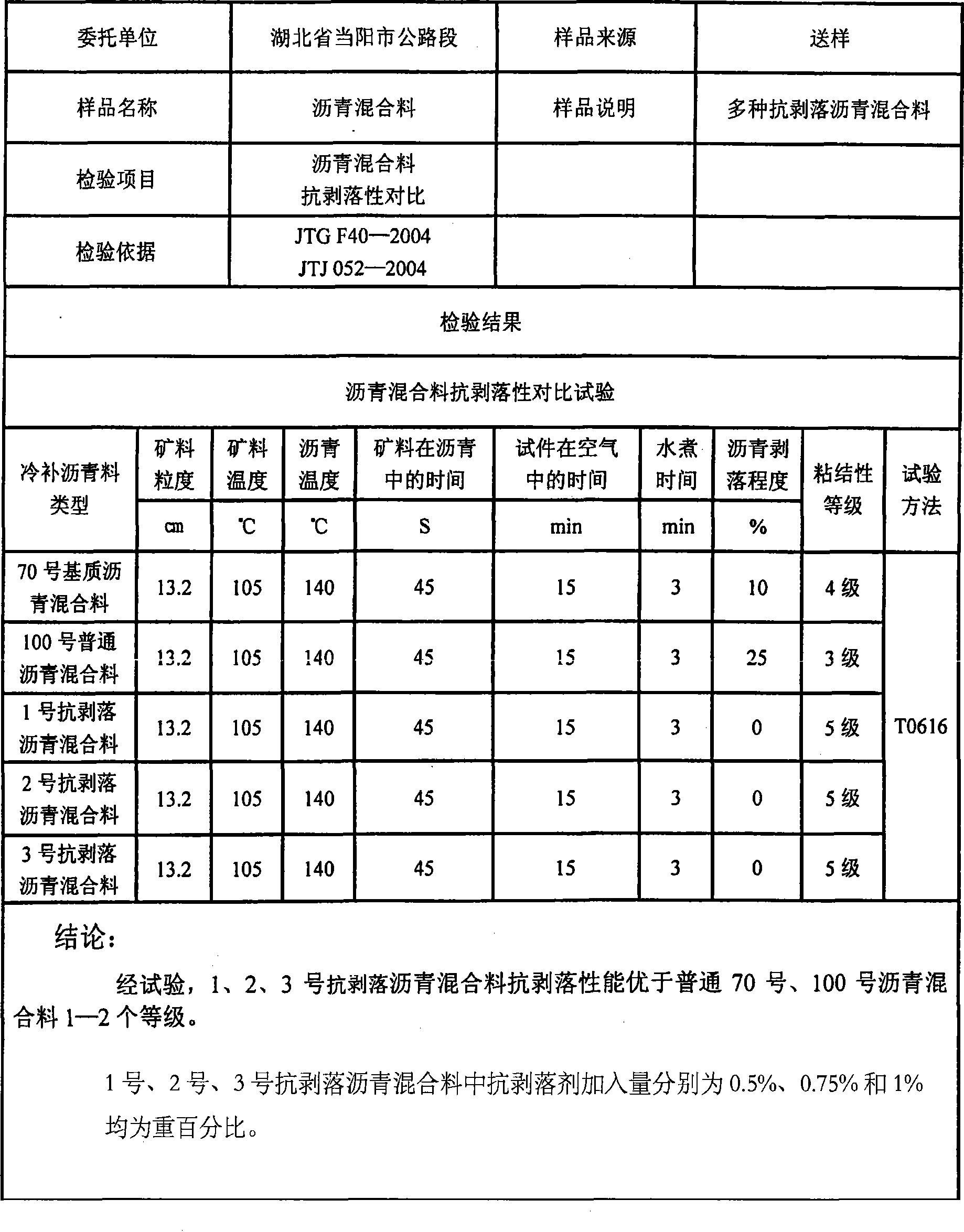

[0018] Table 3

[0019] Experimental report on anti-stripping performance of asphalt mixture materials Table 3

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com