Method for recycling rare earth element yttrium from waste fluorescent powder and preparing resin surface composite coating

A technology of rare earth elements and surface compounding, which is applied in the field of solid waste resource utilization, can solve the problems of the process technology that seldom wastes phosphor powder to be directly used after recycling, and achieves high leaching efficiency, short reaction time, improved hardness and durability. The effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

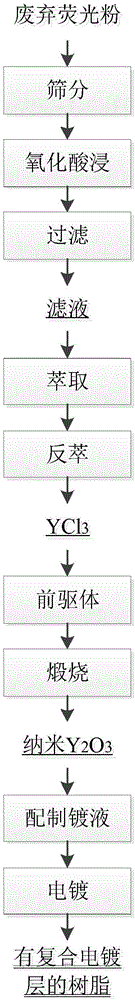

Image

Examples

Embodiment 1

[0040] A method for recovering rare earth element yttrium from waste fluorescent powder and preparing a resin surface composite coating, comprising the following seven steps:

[0041] 1) Screening pretreatment step: after the preliminary crushed waste fluorescent powder is gradually screened through 20 mesh, 60 mesh, 100 mesh, and 200 mesh screens, the 200 mesh undersize is collected, and the undersize accounts for the unsifted powder. 99.9% or more.

[0042] 2) Oxidative acid leaching step: Add sulfuric acid and hydrogen peroxide to the sieved fluorescent powder according to the solid-to-liquid ratio of 1g:30ml for leaching reaction. The concentration of sulfuric acid is 3mol / L, and the volume ratio of hydrogen peroxide and sulfuric acid is 0.04. The reaction was carried out for 60 minutes, and filtered after the reaction to obtain a leach solution containing rare earth elements. The leaching rates of yttrium and europium in the fluorescent powder are both higher than 99.9%....

Embodiment 2

[0048] Embodiment 2: a method for recovering rare earth element yttrium from waste fluorescent powder and preparing a composite coating on the surface of conductive plastics, including the following seven steps:

[0049] 1) Screening pretreatment step: After the preliminary crushed waste fluorescent powder is gradually screened through 20 mesh, 60 mesh, 100 mesh, and 200 mesh screens, the 200 mesh sieves are collected, and the content of rare earth elements in the sieves accounts for More than 99.9% of unsieved powder.

[0050] 2) Oxidative acid leaching step: Add hydrochloric acid and hydrogen peroxide to the sieved fluorescent powder according to the solid-to-liquid ratio of 1g:35ml for leaching reaction. The concentration of hydrochloric acid is 6mol / L, and the volume ratio of hydrogen peroxide and hydrochloric acid is 0.06. The reaction was carried out for 80 minutes, and filtered after the reaction to obtain a leach solution containing rare earth elements. The leaching r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com