Preparation method of granular yttrium cerium oxide solid solution

A technology of cerium oxide and solid solution, which is applied in the field of preparation of small particles of yttrium cerium oxide solid solution, can solve the problems of not getting the best performance of the product, high content of non-rare earth impurities, and difficult rare earth oxides, etc., and achieve easy scale The effect of production, low cost and easy operation

Active Publication Date: 2014-04-30

甘肃稀土新材料股份有限公司

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The existing rare earth oxide solid solution mainly uses directly extracted Y3+ and Ce3+ (hydrochloric acid or nitric acid system) solution as raw material for precipitation, but many companies do not have Y3+ and Ce3+ liquid raw materials, and most of them use oxides as raw materials to dissolve In concentrated acid, it is made into raw materials. Most rare earth oxides are not easily soluble in acid and need to be boiled at high temperature, which is more dangerous

In particular, the dissolution of cerium oxide CeO2 needs continuous boiling in concentrated nitric acid, and only a small amount of dissolution can be achieved by adding hydrogen peroxide, which is very inconvenient

Moreover, the extracted liquid has a high content of non-rare earth impurities so that the performance of the product cannot be maximized.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] Example 2:

Embodiment 2

[0029]

[0030] Example 3:

Embodiment 3

[0032] Embodiment 4:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

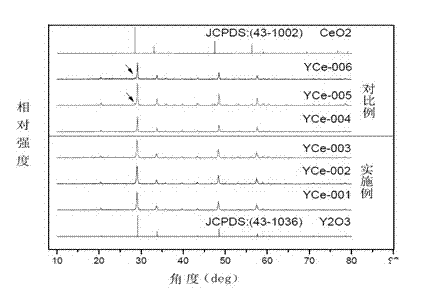

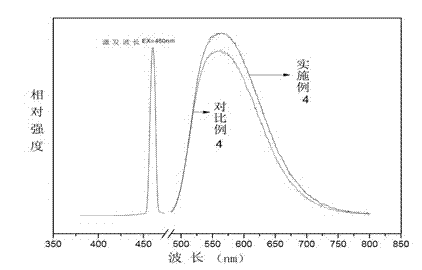

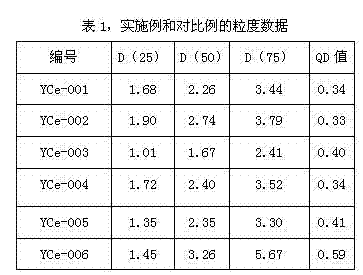

The invention discloses a preparation method of a granular yttrium cerium oxide solid solution. A granular (1-3mum) yttrium cerium rare earth oxide is successfully synthesized from yttrium chloride solution and cerium oxide solid powder (Y2O3 / REO>=99.99%, CeO2 / REO>=99.99%) in the presence of oxalic acid serving as a precipitating agent by adopting a liquid phase precipitation method. According to the preparation method, through controlling influence factors such as feed liquid concentration and precipitation water bath temperature in a synthesis process, the yttrium cerium rare earth oxide which is small in particle size D50 of 1.0-3.0mum and uniform in size distribution is synthesized. The preparation method is short in process, low in cost, convenient to operate, and easy to produce in large scale.

Description

technical field [0001] The invention relates to the technical field of rare earth applied materials, in particular to a method for preparing a small-particle yttrium-cerium oxide solid solution, in particular to a method for preparing a yttrium-cerium oxide solid solution with particles of 1.0-3.0um in size. Background technique [0002] At present, with the development of new material technology, rare earth compounds with controllable particle size show a good market prospect, and small particle yttrium cerium oxide rare earth can be used as raw materials in the field of optoelectronics and luminescence. However, rare earth small particle solid solution oxides are used as raw materials to produce luminescent materials, which are more and more favored in technology. Therefore, in the use of its field, the raw materials are required to have a suitable particle size, and the raw materials are required to have a certain particle size distribution. to improve performance. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/505C04B35/622

Inventor 张尚虎周宏亮唐冬梅李月红李树胜李向东高其栋于化琴

Owner 甘肃稀土新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com