Method for preparing anti-oxidation coatings on surface of molybdenum and molybdenum alloy

An anti-oxidation coating, molybdenum alloy technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problem of poor compatibility, low bonding strength between coating and substrate, acid and alkali corrosion resistance Good compatibility, similar thermal expansion coefficients, and resistance to high temperature oxidation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

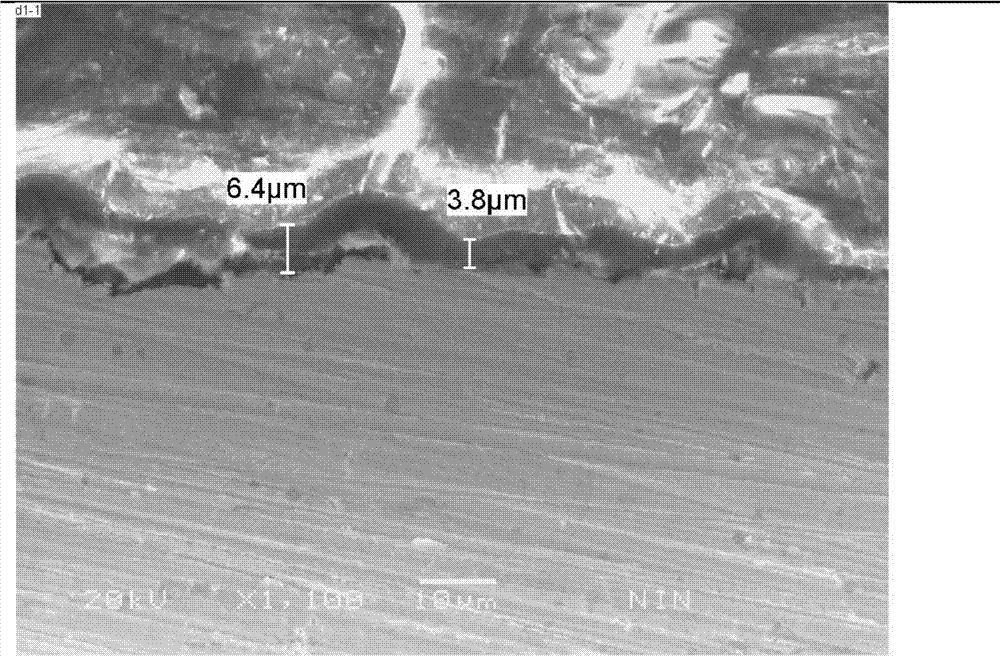

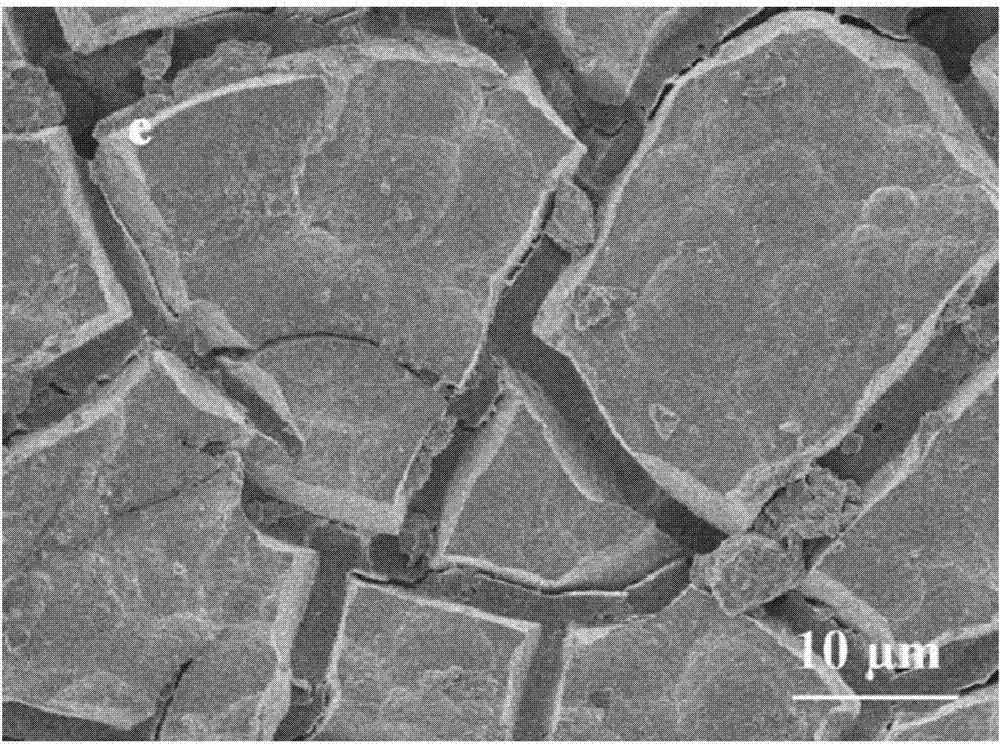

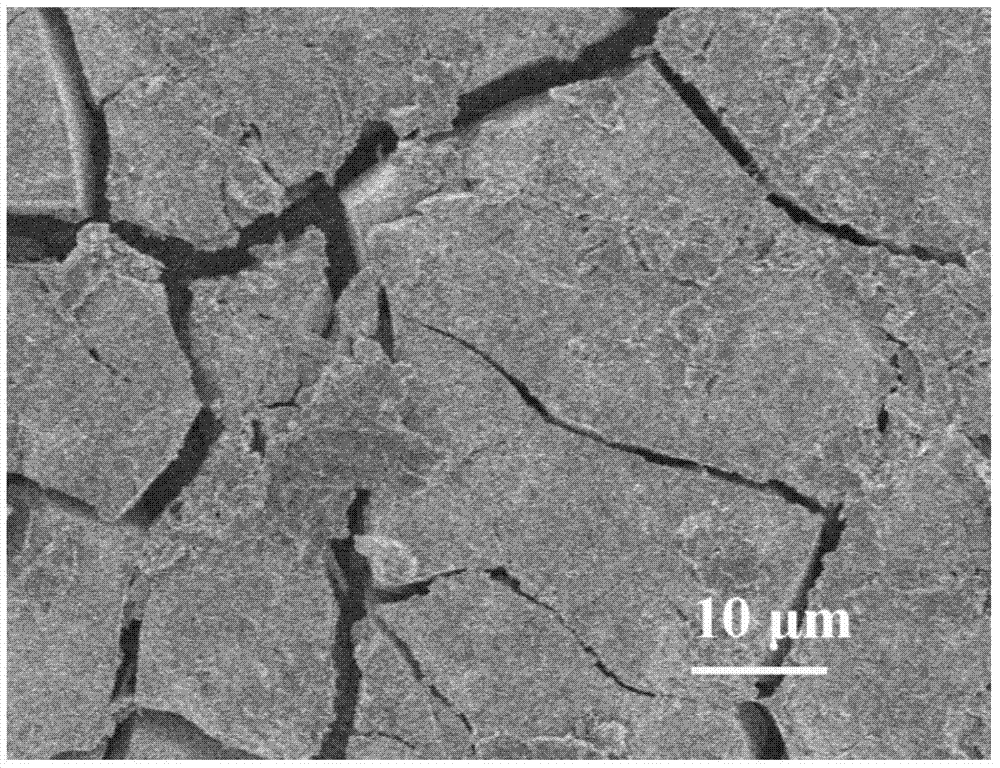

[0023] Step 1: Select a pure molybdenum plate with a purity of 99.95% or more, with an area of 100cm 2 , placed in 30wt% NaOH solution and boiled, ultrasonically cleaned for 1h, taken out and washed with water; placed in 10wt% HCl solution and heated to 90°C for 1.5h; then placed in hydrofluoric acid at 80°C The surface is etched in the solution (5wt%) until uniform pockmarks are formed on the surface. After taking it out, it is washed with deionized water and dried to obtain a pure molybdenum plate substrate.

[0024] Step 2: Mix 5g of hafnium oxychloride and 4g of yttrium chloride and dissolve in 50ml of n-propanol solution to obtain the desired coating solution.

[0025] Step 3: Then apply the coating solution in step 2 evenly on the pockmarked surface of the surface treated substrate, and brush 20 times. After each brushing, put it in a drying oven for 10 minutes at a drying temperature of 120°C, and then place it in the Baking in a muffle furnace for 20 minutes at a fi...

Embodiment 2

[0029] Step 1: Select a pure molybdenum rod with a purity of more than 99.95%, 100mm in length and 15mm in diameter, boil it in 20wt% NaOH solution, clean it with ultrasonic waves for 1 hour, take it out and wash it with water; place it in 20wt% HCl solution heated to 80°C and kept for 1.5h; then placed in a hydrofluoric acid solution (10wt%) at a temperature of 80°C for surface etching until a uniform pockmark was formed on the surface, after taking it out, wash it with deionized water, and dry it. A pure molybdenum rod matrix is obtained.

[0030] Step 2: Mix 8 g of hafnium oxychloride and 4 g of yttrium chloride and dissolve in 50 ml of n-propanol solution to obtain the desired coating solution.

[0031] Step 3: Then apply the coating solution in step 2 evenly on the pockmarked surface of the surface treated substrate, and brush 20 times. After each brushing, put it in the infrared lamp and dry it for 10 minutes at a drying temperature of 130°C, and then place it in the ...

Embodiment 3

[0034] Step 1: Select the rare earth lanthanum-doped TZM alloy plate prepared by powder metallurgy process, with an area of 80cm 2 , placed in 10wt% NaOH solution and boiled, ultrasonically cleaned for 1.5h, taken out and washed with water; placed in 30wt% HCl solution and heated to 80°C for 1h; then placed in hydrofluoric acid at a temperature of 70°C The surface is etched in the solution (15wt%) until uniform pockmarks are formed on the surface. After taking it out, it is washed with deionized water and dried to obtain a TZM alloy plate substrate.

[0035] Step 2: Mix 15g of hafnium oxychloride and 4g of yttrium chloride and dissolve in 80ml of n-propanol solution to obtain the required coating solution.

[0036] Step 3: Then apply the coating solution in step 2 evenly on the pockmarked surface of the surface treated substrate, and brush 30 times. After each brushing, place it in a drying oven for 15 minutes at a drying temperature of 140°C, and then place it in the Bakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com