Preparation method of yttrium stabilized zirconium oxide powder with low monoclinic phase and high activity

A technology of yttrium-stabilized zirconia and monoclinic phase, applied in zirconia and other directions, can solve the problems of low yield of ceramic products and less production of high-precision ceramic parts, and achieve low content of monoclinic phase, less agglomeration, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

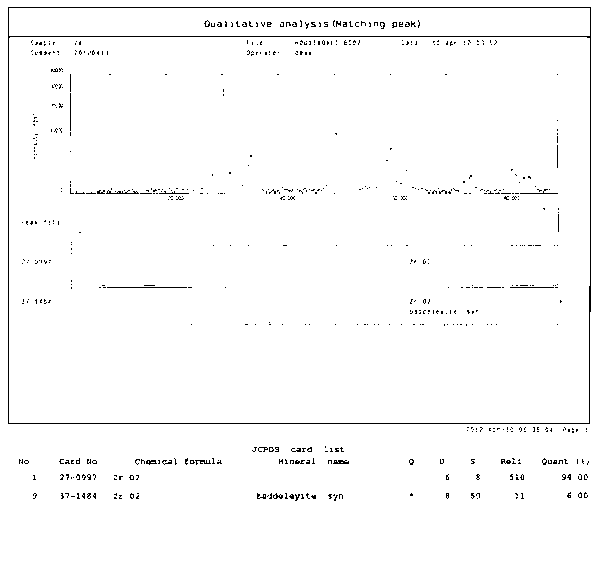

Embodiment 1

[0029] Get 1000g of zirconium oxychloride (ZrOCl 2 ·8H 2 O) make the solution that concentration is 35g / L after mixing and stirring with pure water for 30min, this solution is put into reactor and adds 179g concentrated H 2 SO 4 , the stirring speed is 60 rpm, and the temperature is raised to 90 °C at a rate of 1 °C / min. After 0.5 h of heat preservation, the precipitate is cleaned and filtered, and the precipitate is added to 5.5 Kg of water. After stirring evenly, 120 g of yttrium chloride solution is added, and the stirring rate is 80 revs / min, after stirring for 20 minutes, start to add 25% ammonia water until the Ph reaches 9.5, after aging for 1 hour, clean and filter the precursor of yttria-stabilized zirconia, add 368g of water and 3.68g of polyethylene glycol 4000, and introduce it into the machine Disperse in a disperser for 2 hours, the speed of the disperser is 1200 rpm, then dry at 100°C, then roast at 900°C for 2.5h, and finally undergo jet milling to obtain the...

Embodiment 2

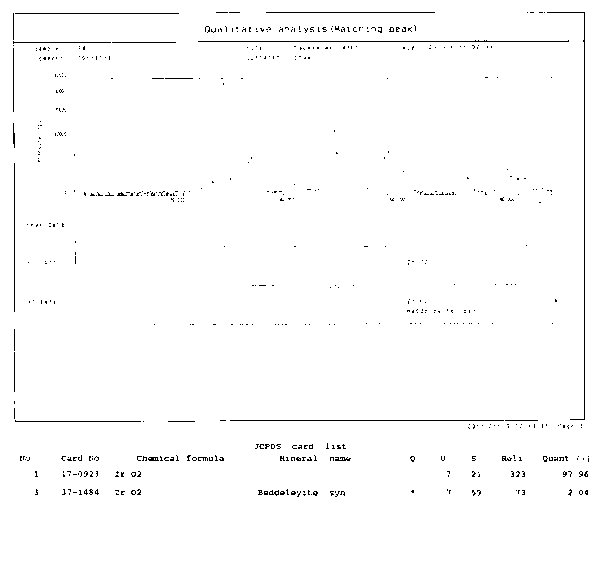

[0032] Get 1000g of zirconium oxychloride (ZrOCl 2 ·8H 2 O) make the solution that concentration is 38g / L after mixing and stirring with pure water for 30min, put this solution into reactor and add 190g concentrated H 2 SO 4 , the stirring speed is 70 rpm / min, the temperature is raised to 90 °C at a rate of 1.5 °C / min, the precipitate is cleaned and filtered after being kept warm for 1 hour, the precipitate is added to 5.5Kg water, and 120g of yttrium chloride solution is added after stirring evenly, and the stirring rate is 90 Turn / min, after stirring for 20 minutes, start to add 25% ammonia water until the Ph reaches 10, after aging for 1.5 hours, wash and filter the precursor of yttria-stabilized zirconia, add 368g of water and 4g of polyethylene glycol 4000, and introduce mechanical dispersion Disperse in the machine for 2.5 hours, the speed of the disperser is 1100 rpm, then dry at 120°C, then bake at 900°C for 3.5h, and finally get the final powder through jet milling....

Embodiment 3

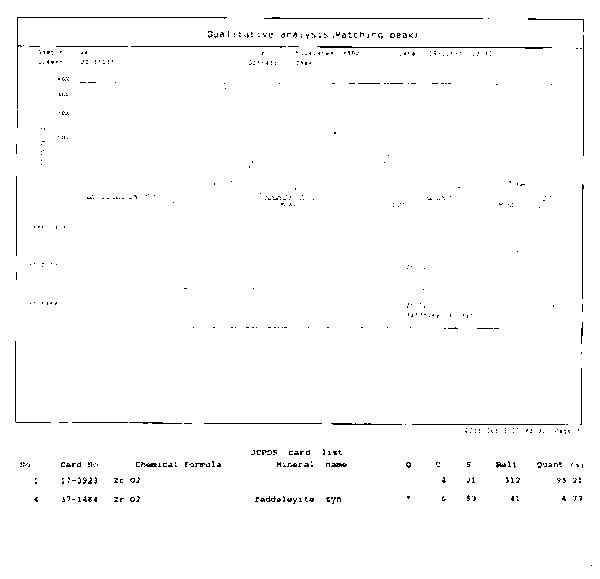

[0035] Get 1000g of zirconium oxychloride (ZrOCl 2 ·8H 2 O) make the solution that concentration is 41g / L after mixing and stirring 30min with pure water, put this solution into reactor and add 185g concentrated H 2 SO 4 , the stirring speed is 80 revs / min, and the temperature is raised to 90°C at a rate of 2°C / min. After 0.6h of heat preservation, the precipitate is cleaned and filtered, and the precipitate is added to 5.5Kg of water. After stirring evenly, 120g of yttrium chloride solution is added, and the stirring rate is 80 rpm, after stirring for 20 minutes, start to add 25% ammonia water until the Ph reaches 9.8, after aging for 2 hours, wash and filter the precursor of yttria-stabilized zirconia, add 368g of water and 6g of polyethylene glycol 4000, and introduce mechanical dispersion Disperse in the machine for 3 hours, the speed of the disperser is 900 rpm, then dry at 100°C, then bake at 950°C for 2h, and finally get the final powder through jet milling.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com