Preparation method of super-hydrophobic paper

A technology for super-hydrophobic paper and pulp, which is applied in paper, papermaking, papermaking and other directions, can solve the problems of insufficient environmental protection, failure, and complicated preparation methods of super-hydrophobic paper, and achieves a solution that reduces free energy, is simple and convenient to operate, and has good waterproof and moisture-proof properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of superhydrophobic paper:

[0032] Step 1, ultrasonically disperse 1 g of octadecylamine in 100 mL of deionized water, and ultrasonically emulsify for 8 hours to form octadecylamine emulsion.

[0033] In step 2, the octadecylamine emulsion and A4 paper pulp are uniformly mixed at a volume ratio of 1:1 to form a stearylamine-pulp mixture.

[0034] Step 3, mixing the octadecylamine-pulp mixed liquor with tannic acid at a mass ratio of 1:1, then adding chlorine hexahydrate to it at a mass ratio of 1:1 according to the mass ratio of tannic acid to aluminum chloride hexahydrate Aluminum.

[0035] Step 4, adjust the pH value of the mixed solution obtained in Step 3 to 8 with NaOH.

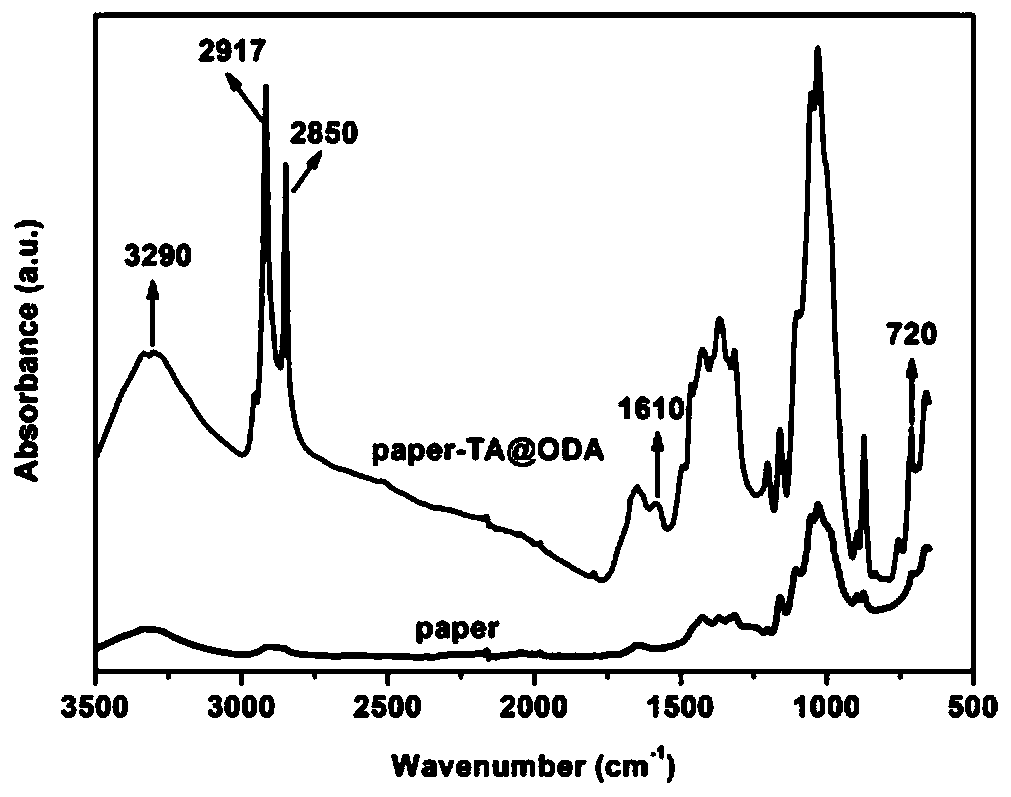

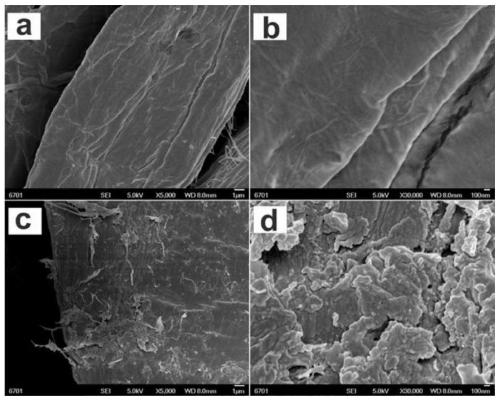

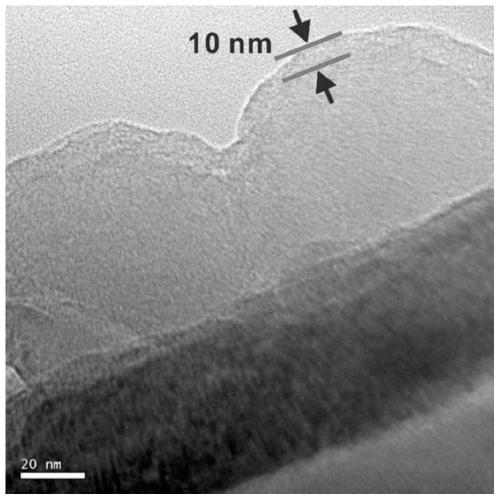

[0036] Step 5: stirring and reacting the mixed solution after adjusting the pH value for 24 hours to form a paper fiber slurry modified with tannic acid@octadecylamine (TA@ODA) microcapsules.

[0037] Step 6: Centrifuge the pulp modified by TA@ODA, flatten it into ...

Embodiment 2

[0039] A kind of preparation method of superhydrophobic paper:

[0040] Step 1, ultrasonically disperse 2 g of octadecylamine in 100 mL of deionized water, and ultrasonically emulsify for 10 h to form octadecylamine emulsion.

[0041] In step 2, the stearylamine emulsion and A4 paper pulp are uniformly mixed at a volume ratio of 1:5 to form a stearylamine-pulp mixture.

[0042] Step 3, mixing the octadecylamine-pulp mixed liquor with tannic acid at a mass ratio of 1:5, and then adding chlorine hexahydrate at a mass ratio of 1:3 according to tannic acid and aluminum chloride hexahydrate Aluminum.

[0043] Step 4, adjusting the pH value of the mixed solution in Step 3 to 9 with NaOH.

[0044] Step 5: stirring and reacting the mixed solution after adjusting the pH value for 12 hours to form a paper fiber slurry modified with tannic acid@octadecylamine microcapsules.

[0045] Step 6: Centrifuge the pulp modified by TA@ODA, flatten it into shape, and dry it at 60°C for 40 minute...

Embodiment 3

[0047] A kind of preparation method of superhydrophobic paper:

[0048] Step 1, ultrasonically disperse 2 g of octadecylamine in 100 mL of deionized water, and ultrasonically emulsify for 10 h to form octadecylamine emulsion.

[0049] In step 2, the octadecylamine emulsion and the filter paper pulp are uniformly mixed at a volume ratio of 1:5 to form a stearylamine-pulp mixture.

[0050] Step 3, mixing the octadecylamine-pulp mixed liquor with tannic acid at a mass ratio of 1:5, and then adding chlorine hexahydrate at a mass ratio of 1:3 according to tannic acid and aluminum chloride hexahydrate Aluminum.

[0051] Step 4, adjusting the pH value of the mixed solution to 8 with NaOH.

[0052] Step 5: stirring and reacting the mixed solution after adjusting the pH value for 24 hours to form a paper fiber slurry modified with tannic acid@octadecylamine microcapsules.

[0053] Step 6: centrifuge the pulp modified by TA@ODA, flatten it into shape, and dry it at 80°C for 60 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com