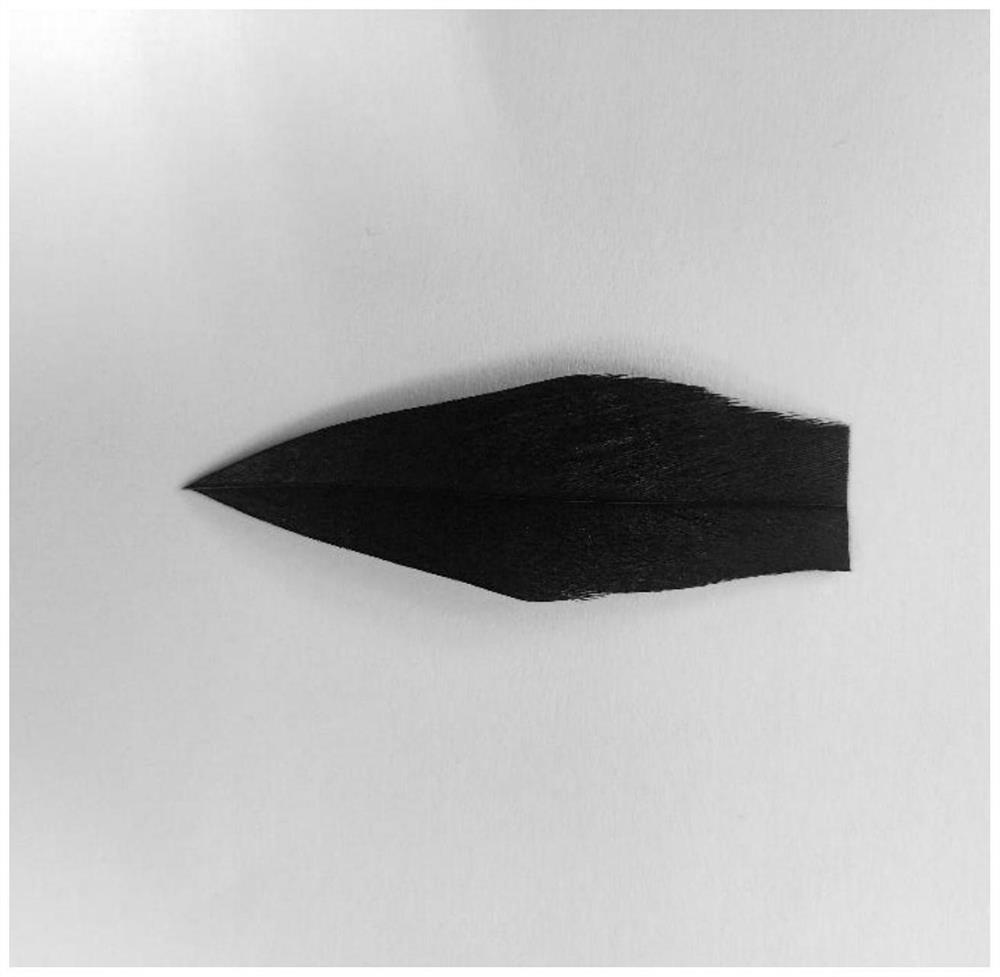

Sodium alginate modified amphiphilic feather as well as preparation method and application thereof

A sodium alginate and amphiphilic technology, applied in the field of biologically derived photothermal materials, can solve the problems of difficult biodegradation, high cost, and large-scale application obstacles, and achieve good biodegradability, reduce heat loss, and fast water The effect of transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] material preparation

[0030] 1) Disperse 20 mg of sodium alginate powder into 10 ml of water, oscillate and mix for 3 minutes, and ultrasonicate for 10 minutes to obtain a sodium alginate solution with a good dispersion and a concentration of 2 mg / ml;

[0031] 2) Disperse 10ml of absolute ethanol into 10ml of sodium alginate solution, oscillate and mix for 2 minutes, and ultrasonicate for 5 minutes to obtain a mixed solution with good dispersion and a sodium alginate concentration of 1mg / ml;

[0032] 3) After the mixed solution was sprayed on one side of the feather for 5 times, it was dried under vacuum at 40° C. for 12 hours to obtain an amphiphilic feather assembled with a layer of sodium alginate.

[0033] efficiency test

[0034] 1) Place the amphiphilic feather with the hydrophilic side facing down in a beaker filled with 3% NaCl solution;

[0035] 2) Place the beaker under a xenon lamp with a solar intensity (1kW / m2) for 8 hours, and obtain the real-time chang...

Embodiment 2

[0040] material preparation

[0041] 1) Disperse 40mg of sodium alginate powder into 10ml of water, oscillate and mix for 5 minutes, and ultrasonicate for 15 minutes to obtain a sodium alginate solution with a good dispersion and a concentration of 4mg / ml;

[0042] 2) Disperse 10ml of absolute ethanol into 10ml of sodium alginate solution, oscillate and mix for 3 minutes, and sonicate for 10 minutes to obtain a mixed solution with good dispersion and a sodium alginate concentration of 2mg / ml;

[0043] 3) After spraying the mixed solution on one side of the feather for 8 times, it was dried under vacuum at 40° C. for 12 hours to obtain an amphiphilic feather assembled with a layer of sodium alginate.

[0044] efficiency test

[0045] 1) Place the amphiphilic feather with the hydrophilic side down in a beaker filled with 5% NaCl solution;

[0046] 2) Place the beaker under a xenon lamp with a solar intensity (1kW / m2) for 8 hours, and obtain the real-time change curve of the ma...

Embodiment 3

[0050] material preparation

[0051] 1) Disperse 80mg of sodium alginate powder into 10ml of water, shake and mix for 7 minutes, and ultrasonicate for 20 minutes to obtain a sodium alginate solution with a good dispersion and a concentration of 8mg / ml;

[0052] 2) Disperse 10ml of absolute ethanol into 10ml of sodium alginate solution, oscillate and mix for 5 minutes, and sonicate for 15 minutes to obtain a mixed solution with good dispersion and a sodium alginate concentration of 4mg / ml;

[0053] 3) After spraying the mixed solution on one side of the feather 8 times, it was dried in vacuum at 40° C. for 16 hours to obtain an amphiphilic feather assembled with a layer of sodium alginate.

[0054] efficiency test

[0055] 1) Place the amphiphilic feather with the hydrophilic side down in a beaker filled with 8% NaCl solution;

[0056] 2) Place the beaker under a xenon lamp with a solar intensity (1kW / m2) for 8 hours, and obtain the real-time change curve of the mass of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com