Preparation method of super-hydrophobic fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of preparation method 1 of superhydrophobic cotton fabric

[0032] (1) 1g of octadecylamine is ultrasonically dispersed in 100ml of deionized water to form a nano octadecylamine finishing agent;

[0033] (2) Combine the sand core funnel suction filter bottle and vacuum pump into a vacuum suction filtration device, put a Φ50mm cotton fabric on the sand core of the sand core funnel, soak it with deionized water, and use the nano octadecylamine finishing agent The mass ratio to the cotton fabric is 50:1. Weigh the nano octadecylamine finishing agent and pour it into the funnel of the sand core for vacuum filtration. The vacuum degree is 0.098MPa, the pumping speed of the vacuum pump is 60L / min, and the filtration time for 60min.

[0034] (3) heating and drying the fabric obtained in step (2), wherein the heating temperature is 50° C., and the heating time is 60 minutes to obtain a superhydrophobic fabric.

Embodiment 2

[0035] Embodiment 2 A kind of preparation method of superhydrophobic cotton fabric 2

[0036] (1) 1g of octadecylamine is ultrasonically dispersed in 100ml of deionized water to form a nano octadecylamine finishing agent;

[0037] (2) Combine the sand core funnel suction filter bottle and vacuum pump into a vacuum suction filtration device, put a Φ50mm cotton fabric on the sand core of the sand core funnel, soak it with deionized water, and use the nano octadecylamine finishing agent The mass ratio to the cotton fabric is 30:1. Weigh the nano octadecylamine finishing agent and pour it into the sand core funnel for vacuum filtration. The vacuum degree is 0.098MPa, the vacuum pump speed is 60L / min, and the filtration time is 0.098MPa. 30min;

[0038] (3) heating and drying the fabric obtained in step (2), wherein the heating temperature is 80° C., and the heating time is 30 minutes to obtain a superhydrophobic fabric.

Embodiment 3

[0039] Embodiment 3 A kind of preparation method of superhydrophobic polyester fabric 3

[0040] (1) 1g of octadecylamine is ultrasonically dispersed in 100ml of deionized water to form a nano octadecylamine finishing agent;

[0041] (2) Combine the sand core funnel suction filter bottle and vacuum pump into a vacuum suction filtration device, put a Φ50mm polyester fabric on the sand core of the sand core funnel, soak it with deionized water, and use the nano octadecylamine finishing agent The mass ratio to the cotton fabric is 50:1. Weigh the nano octadecylamine finishing agent and pour it into the funnel of the sand core for vacuum filtration. The vacuum degree is 0.098MPa, the pumping speed of the vacuum pump is 60L / min, and the filtration time 60min;

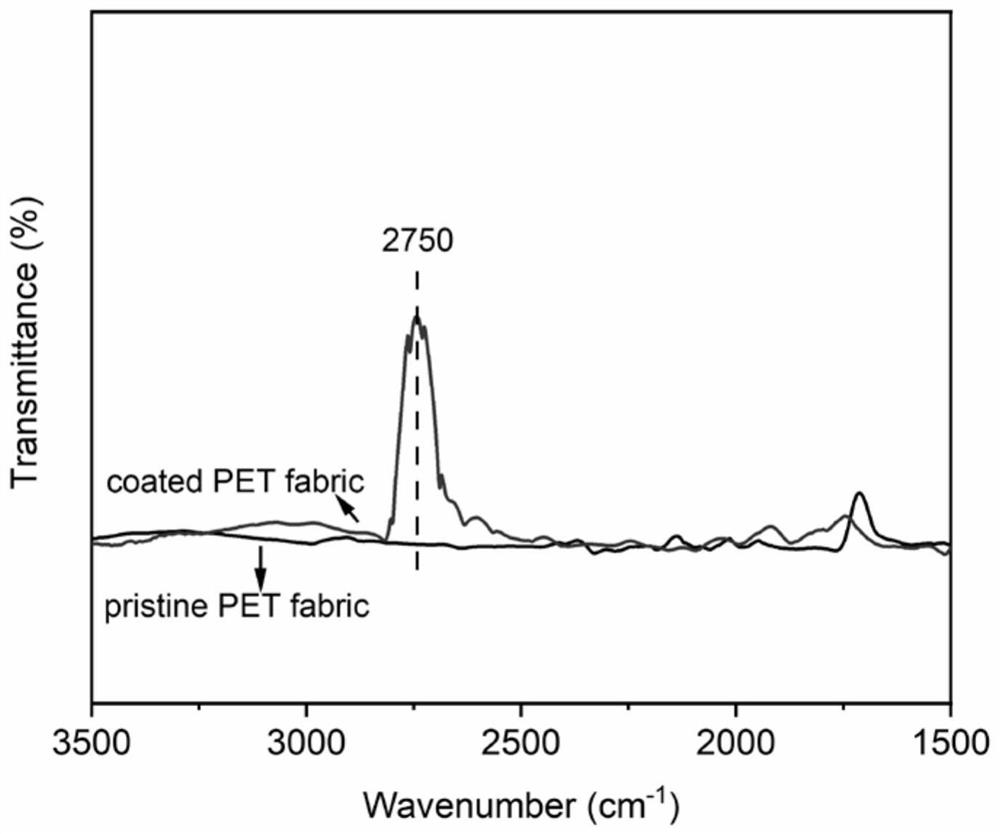

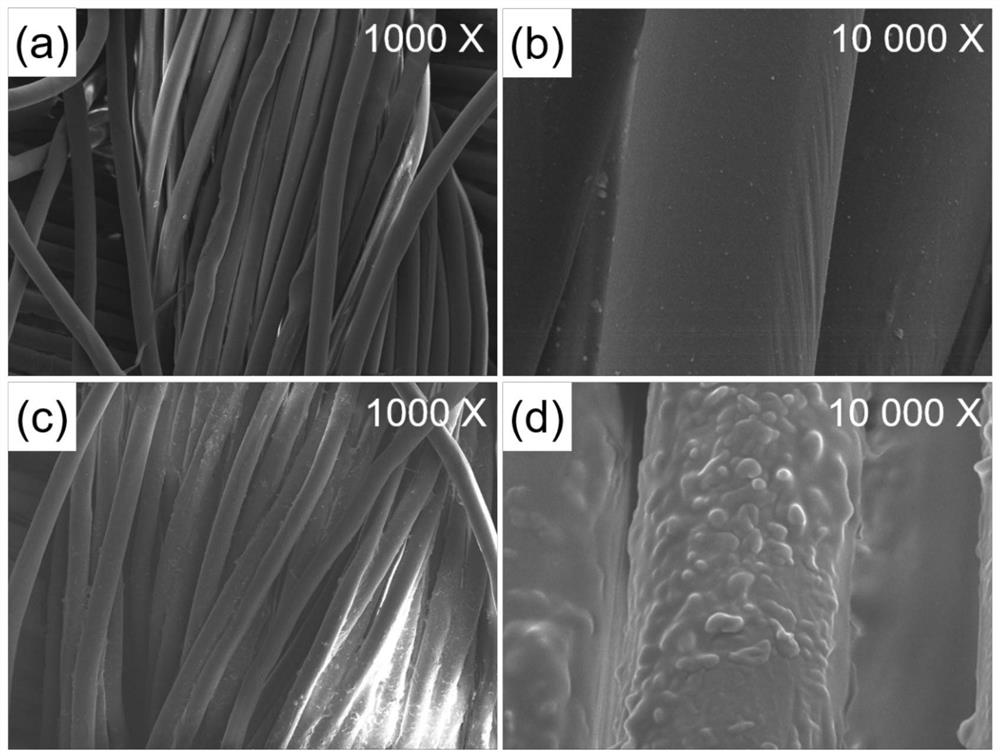

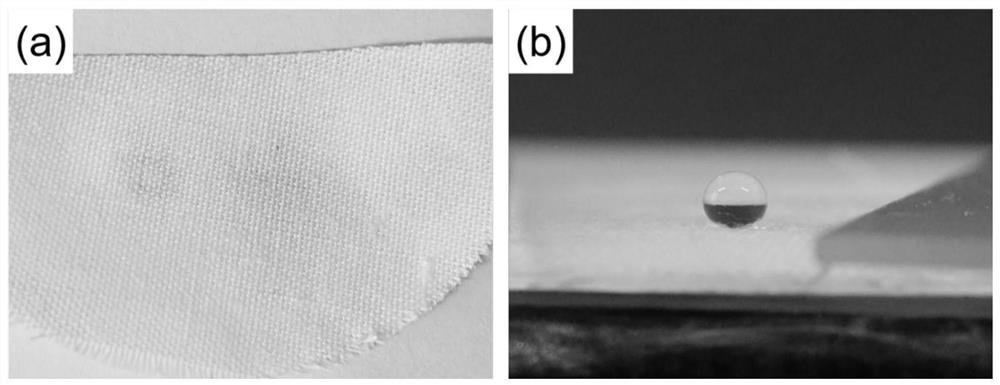

[0042] (3) Heat and dry the fabric obtained in step (2), wherein the heating temperature is 50° C., and the heating time is 60 minutes to obtain a superhydrophobic fabric. And carry out total reflection infrared test on it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com