Gold product surface nano multi-layer composite anti-scratching film and preparation method thereof

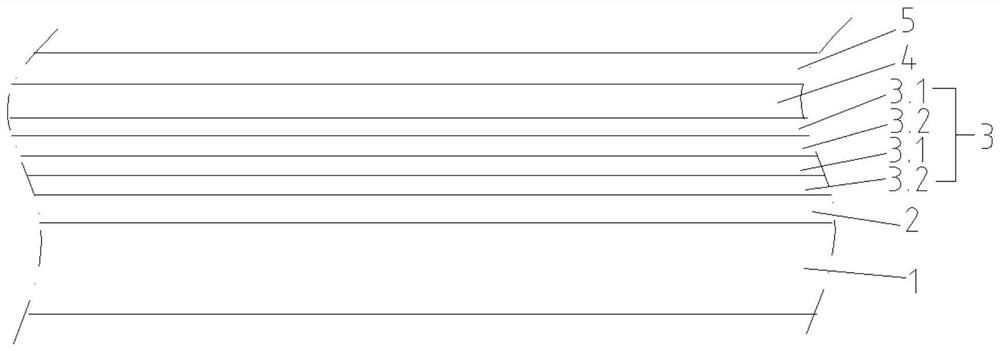

A nano-multi-layer and gold product technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of lack of strong support, scratch resistance and easy scratching of the top transparent medium layer , to achieve the effect of adapting to the production rhythm, fast deposition rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment one is with nano-rose gold / nanometer Al 2 o 3 Multilayer film is taken as an example, the rose gold target and Al 2 o 3 ceramic target.

[0081] 1) Furnace vacuuming: put the cleaned rose gold ornaments into the rotating hanger in the furnace, and draw a background vacuum of 3--6x10 -3 Pa; if the last process is to complete the ion-plating imitation rose gold (TiCN) coating on stainless steel and brass ornaments in this furnace, stop the titanium target, stop supplying nitrogen and acetylene, fill Ar gas to 5Pa, 7 minutes, stop For Ar, background vacuum up to 4x10 -3 Pa.

[0082] 2) Glow ion cleaning: fill with Ar gas 2Pa, turn on the pulse bias voltage, --600V, duty cycle 50%, and glow cleaning for 5 minutes.

[0083] 3) Play transition layer

[0084] For rose gold jewelry, fill with Ar gas 3x10 -1 Pa, bias voltage--80v, turn on the rose gold cathode arc source (50A) and DC magnetron sputtering rose gold target (3A) at the same time, mix plating for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com