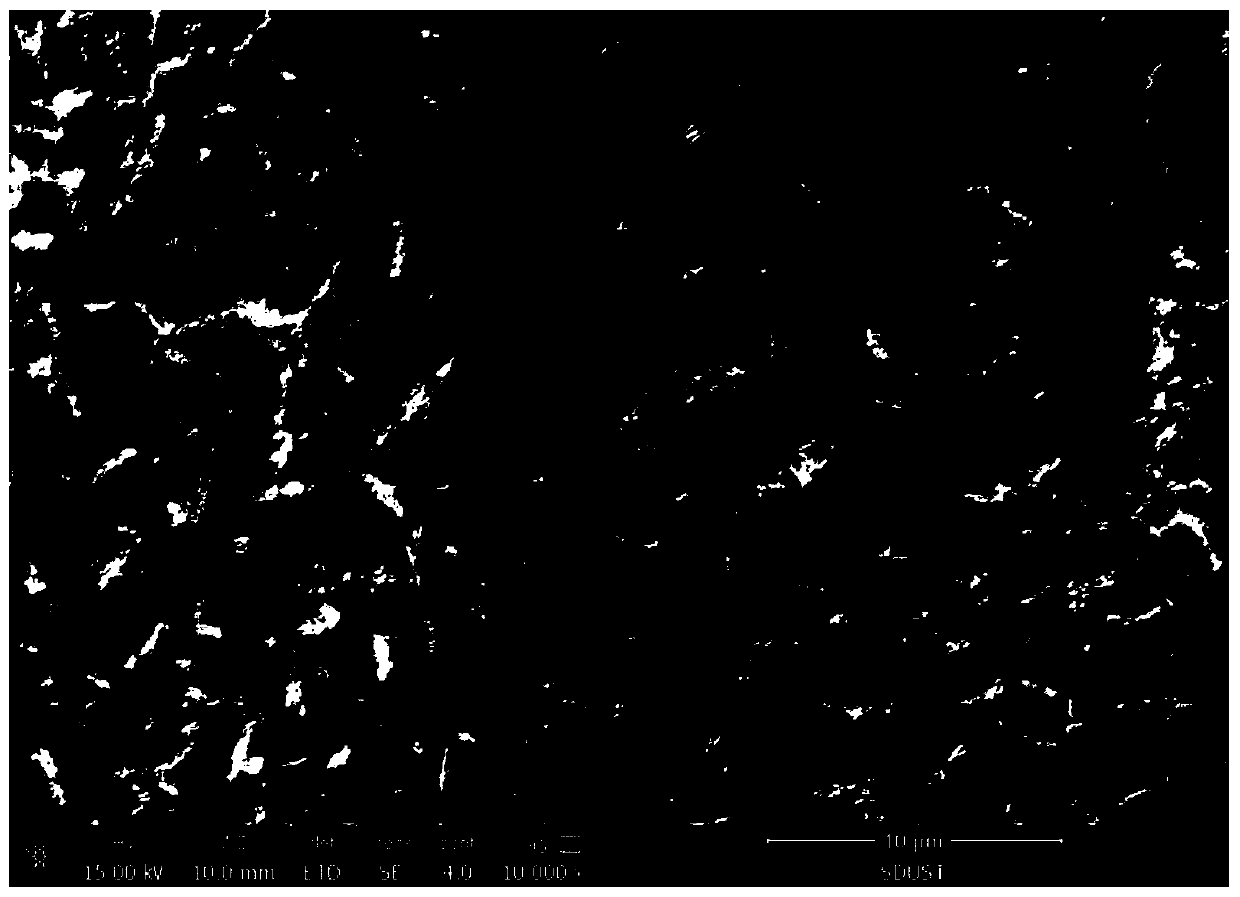

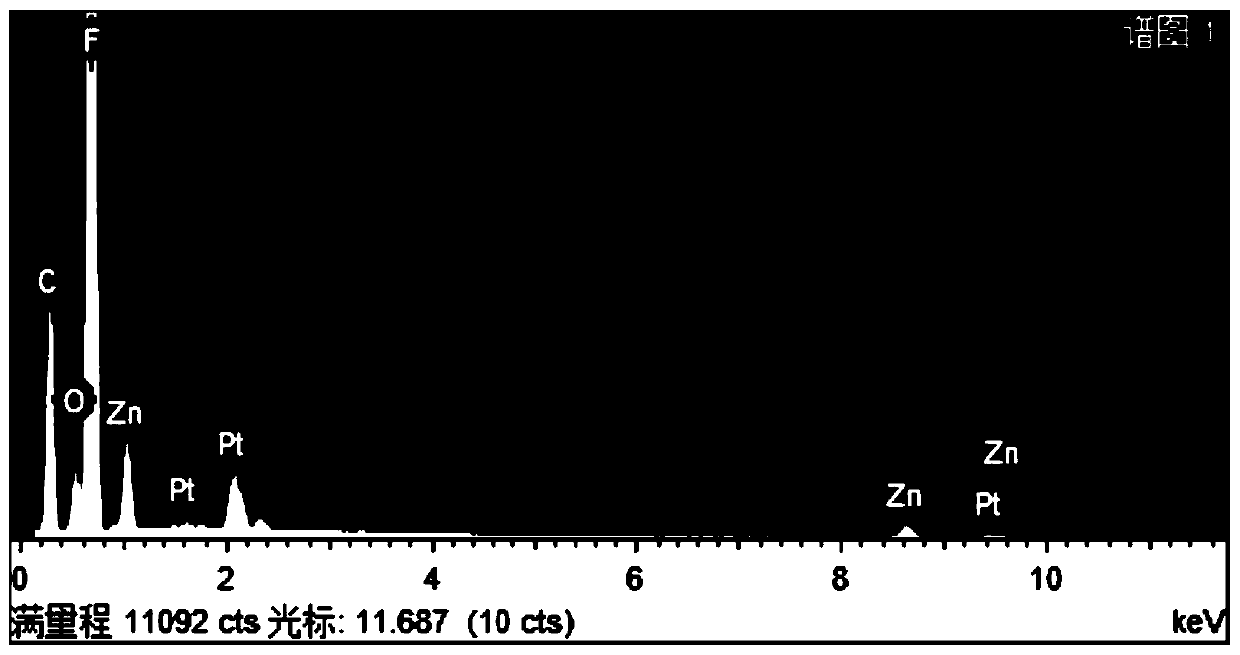

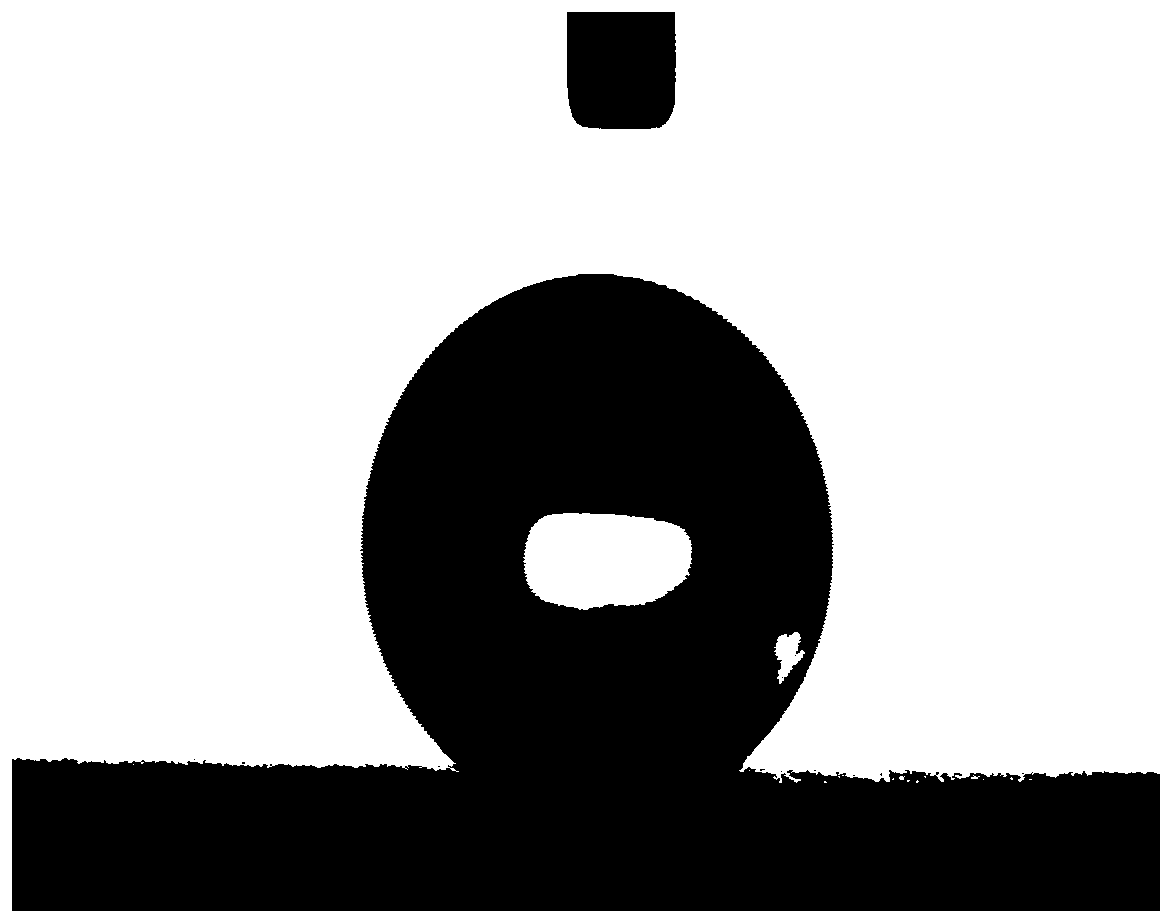

Super-hydrophobic Zn-poly tetra fluoro ethylene (PTFE) composite electrodeposition layer and preparation method thereof

A composite electrodeposition, super-hydrophobic technology, applied in coatings, electrolytic coatings, etc., can solve the problems of weak binding force, poor stability, limiting the practical application of super-hydrophobic functional surfaces, etc., to achieve low production cost, avoid corrosion, good industrial The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of superhydrophobic Zn-PTFE composite electrodeposition layer comprises the following steps in turn:

[0047] (1) Select X90 pipeline steel (20×50×3mm) as the matrix sample, pure zinc plate (20×50×5mm) as the counter electrode sample, and polish the processed X90 pipeline steel and pure zinc sample with water sandpaper Smooth to 2500#, and put the polished sample into acetone and absolute ethanol for 5 minutes for ultrasonic cleaning to remove grease and pollutants on the surface of the sample;

[0048] (2) Immerse the above-mentioned cleaned steel sample into a mixed aqueous solution containing 30g / L sodium hydroxide, 20g / L sodium carbonate, 20g / L sodium phosphate and 10g / L sodium silicate (60°C ) to remove oil by alkali washing for 15 minutes. 2 SO 4 Pickling and activation in aqueous solution (room temperature) for 15s, cleaning and drying after taking out, in order to improve the binding force between the composite electrodeposited layer and...

Embodiment 2

[0054] The preparation method of superhydrophobic Zn-PTFE composite electrodeposition layer comprises the following steps in turn:

[0055] (1) Select X90 pipeline steel (20×50×3mm) as the matrix sample, pure zinc plate (20×50×5mm) as the counter electrode sample, and polish the processed X90 pipeline steel and pure zinc sample with water sandpaper Smooth to 2500#, and put the polished sample into acetone and absolute ethanol for 5 minutes for ultrasonic cleaning to remove grease and pollutants on the surface of the sample;

[0056] (2) Immerse the above-mentioned cleaned steel sample into a mixed aqueous solution containing 30g / L sodium hydroxide, 20g / L sodium carbonate, 20g / L sodium phosphate and 10g / L sodium silicate (60°C ) to remove oil by alkali washing for 15 minutes. 2 SO 4 Pickling and activation in aqueous solution (room temperature) for 15s, cleaning and drying after taking out, in order to improve the binding force between the composite electrodeposited layer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com