Method of extracting aluminum oxide by leaching flyash with hydrochloric acid

A technology of fly ash and alumina, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of large and complex impurity removal system, high cost, high energy consumption, etc., to overcome the high energy consumption of crystallization, Reduced energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

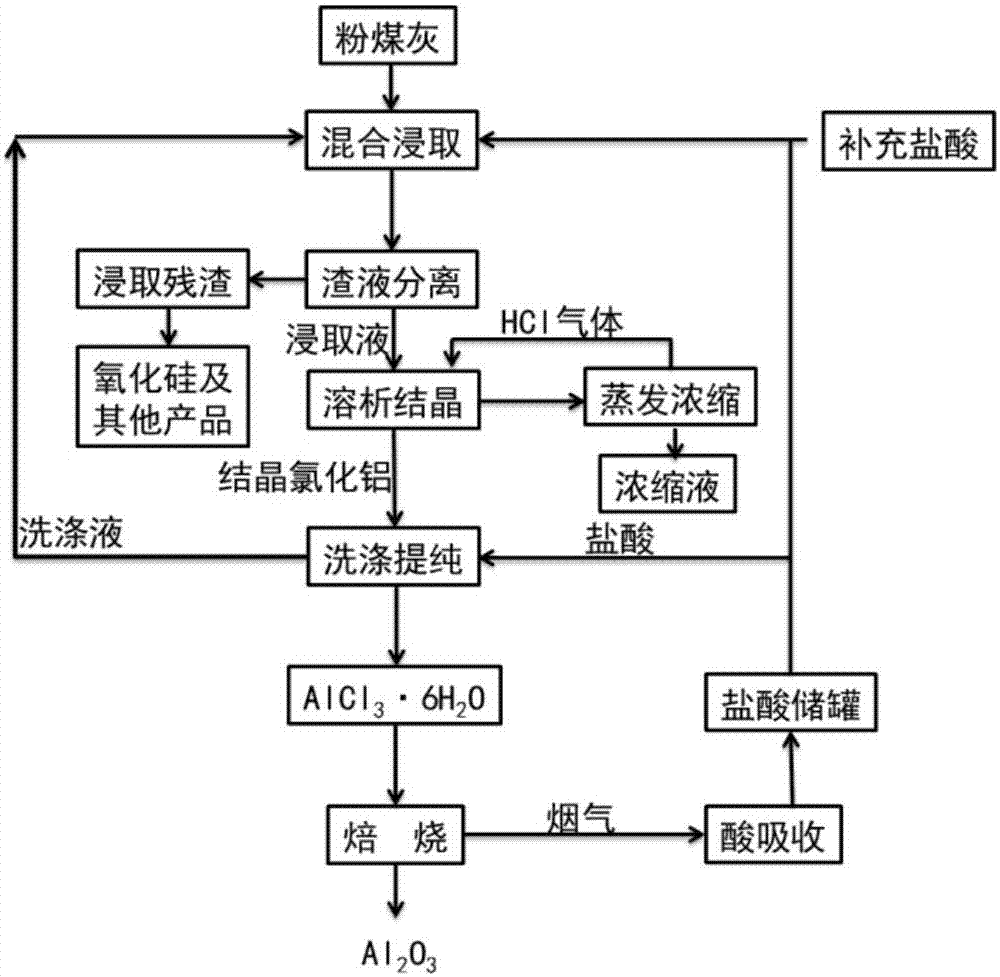

[0041] A method for extracting alumina by leaching fly ash with hydrochloric acid, comprising the following steps:

[0042](1) High-alumina active fly ash (40% alumina content) and hydrochloric acid (31%) are mixed according to the ash-acid ratio of 0.9, and the alumina in the ash is dissolved by reacting at 130°C and 1.2Mpa for 2h.

[0043] (2) step (1) reacts and obtains slurry to form the leaching residue that does not contain floating matter and the leaching residue of high silicon after settling, washing and filtering, and the leaching liquor is used for extracting crystalline aluminum chloride, and leaching residue can be Harmless landfill or further extraction of silicon oxide.

[0044] (3) Pass into the leaching liquid that step (2) obtains and be that 95% HCl gas of dry purity, make the aluminum chloride crystallization in the leaching liquid form aluminum chloride hexahydrate crystal and separate out, through solid-liquid separation Obtain crude aluminum chloride an...

Embodiment 2

[0051] (1) High-alumina activated fly ash (60% alumina content) and hydrochloric acid (29%) are mixed according to the ash-acid ratio of 1, and the alumina in the ash is dissolved by reacting at 150°C and 1.5Mpa for 1 hour.

[0052] (2) step (1) reacts and obtains slurry to form the leaching residue that does not contain floating matter and the leaching residue of high silicon after settling, washing and filtering, and the leaching liquor is used for extracting crystalline aluminum chloride, and leaching residue can be Harmless landfill or further extraction of silicon oxide.

[0053] (3) Pass into the leaching liquid that step (2) obtains and be that 95% HCl gas of dry purity, make the aluminum chloride crystallization in the leaching liquid form aluminum chloride hexahydrate crystal and separate out, through solid-liquid separation Obtain crude aluminum chloride and residual liquid, when the concentration of hydrogen chloride in the leaching liquid reaches 30%, stop feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com