Preparation and application of layered double hydroxides with diethylenetriaminepentaacetic acid intercalation

A technology of diethylenetriaminepentaacetic acid and hydroxide, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of biomass reduction, plant root activity, and chlorophyll content decline, achieving low consumption and low cost , the effect of simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

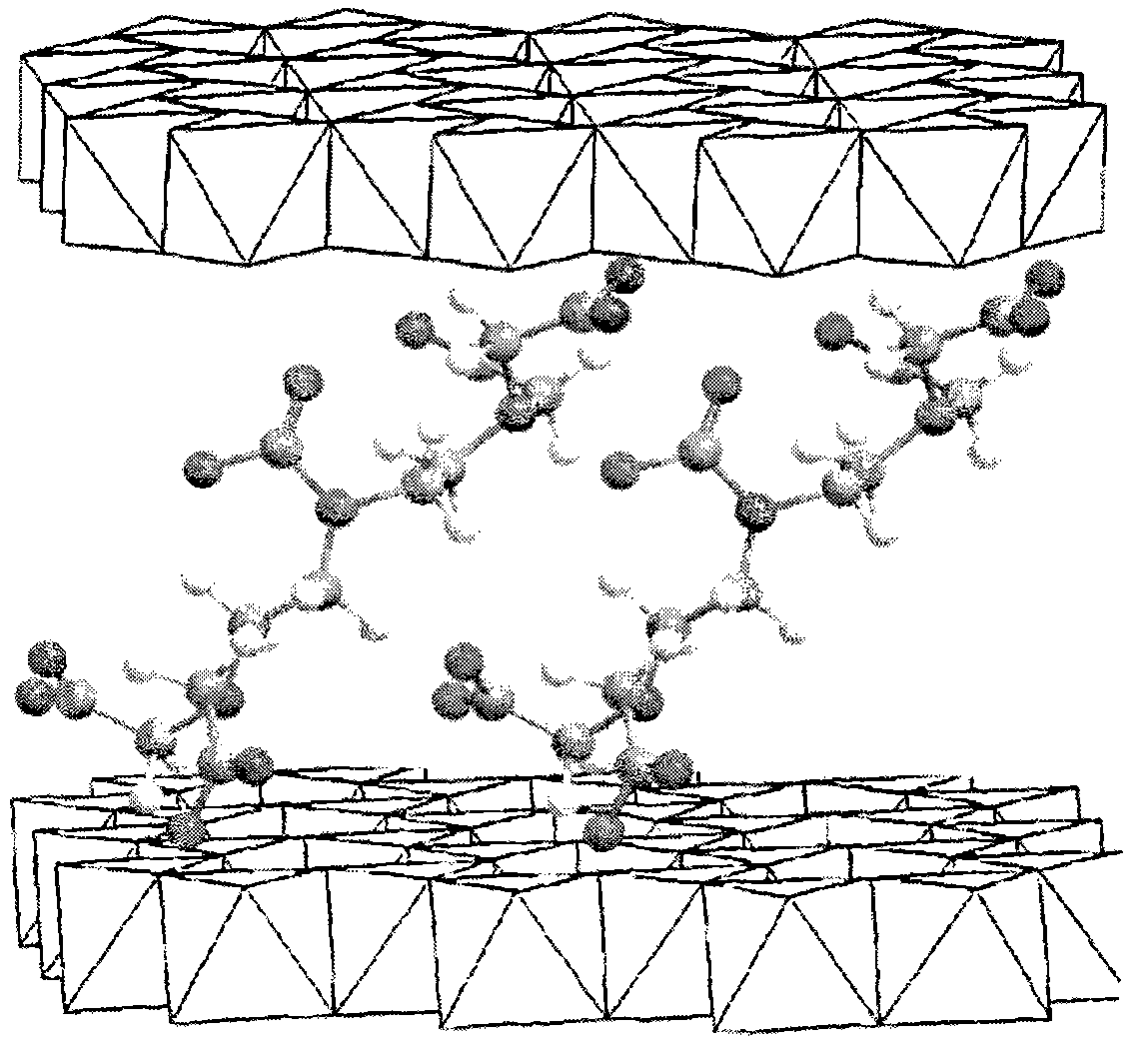

[0026] Embodiment 1: Preparation of Mg-Al-DTPA LDH

[0027] Weigh 135.63g MgCl 2 ·6H 2 O and 80.48g AlCl 3 ·6H 2 0, dissolved in 2000ml deionized water under agitation; take 32.45g DTPA, add 37ml weight percent concentration and be 25% ammonia solution, mix for subsequent use; measure 210ml 25% ammoniacal water, add 840ml deionized water to dilute for subsequent use; Under the condition of vigorous stirring, add the prepared DTPA solution and ammonia solution into the mixed salt solution, stir vigorously for 20 minutes and then leave it to age for 60 minutes; transfer the mixed solution to a Buchner funnel, rinse it repeatedly with deionized water and Suction filter 8 times to remove excess ammonia water, collect the gel filter cake in the Buchner funnel into a jar, place in an oven at a constant temperature of 80°C, take out the gel in the jar after 24 hours, dry at 65°C, and grind After that, the diethylenetriaminepentaacetic acid-intercalated layered double metal hydrox...

Embodiment 2

[0028] Embodiment 2: Mg-Al-DTPA LDH adsorption aqueous solution Pb 2+ Applications

[0029] Configure a series of different Pb 2+ Concentration of the solution as the working solution, respectively measure 50ml and put it in a 100ml centrifuge tube, weigh 0.05g of Mg-Al-DTPA LDH and add the added Pb 2+ In the centrifuge tube contaminated with the working solution, the ratio of Mg-Al-DTPA LDH to the dirty solution is 1g / L, shake at constant temperature for 12 hours, take the supernatant after high-speed centrifugation, and measure the Pb in the solution with an atomic absorption spectrophotometer 2+ Concentration, according to Pb in the working solution 2+ The concentration difference before and after the concentration was used to calculate the adsorption amount of Mg-Al-DTPA LDH.

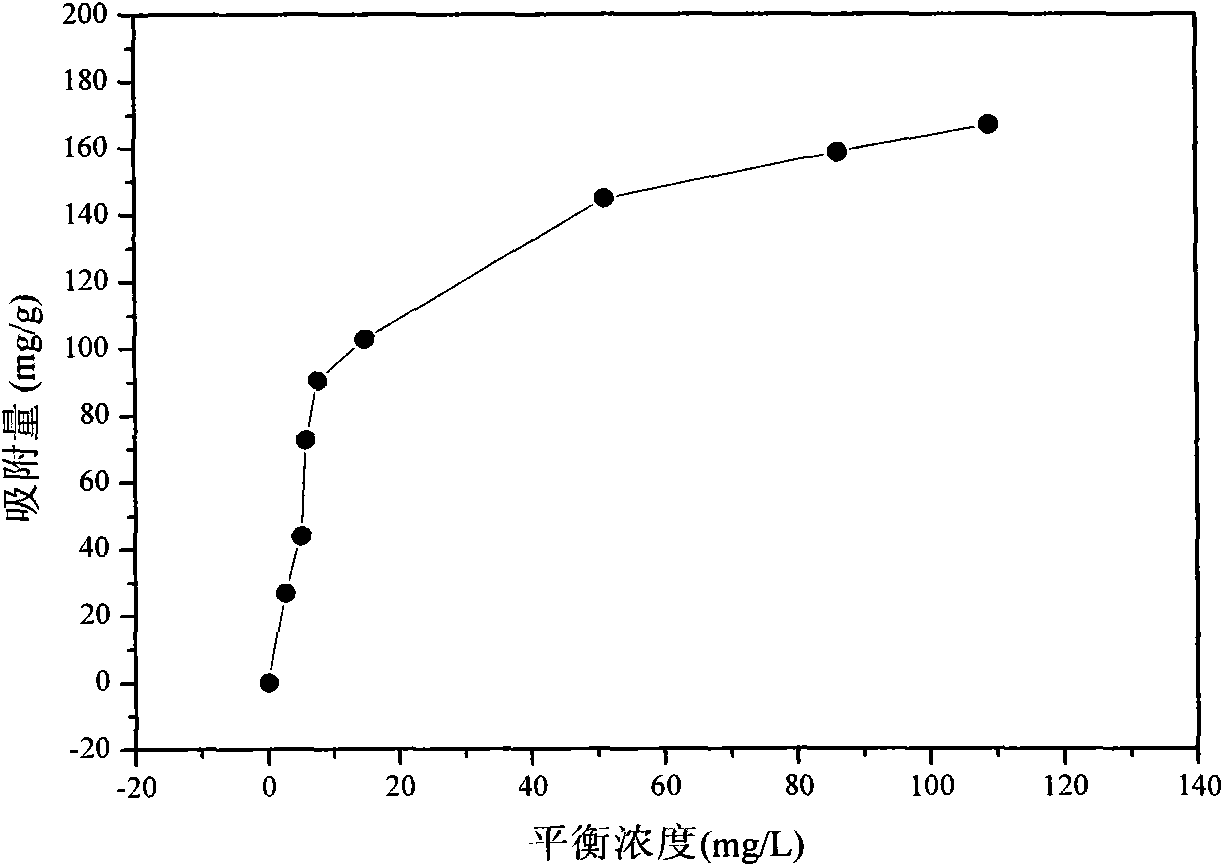

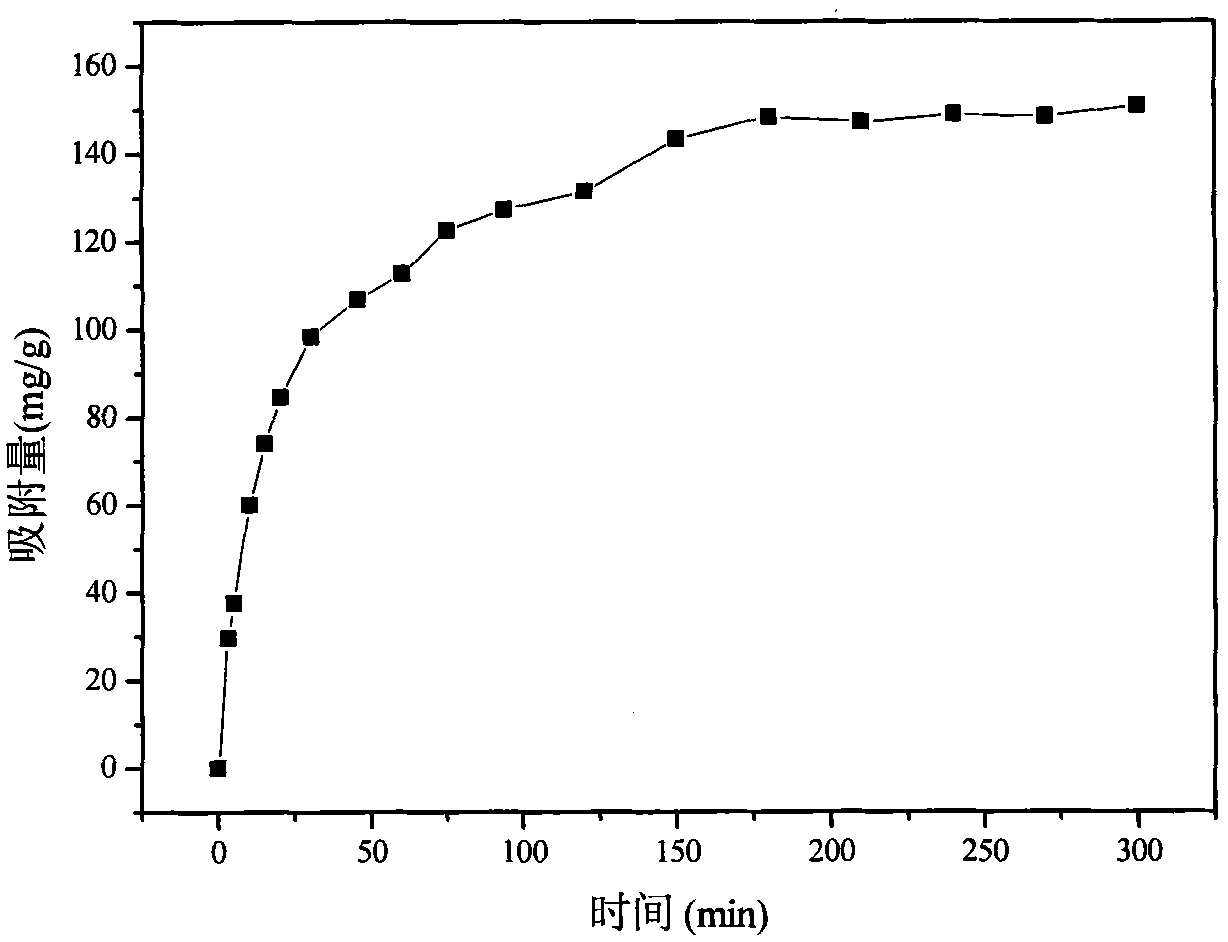

[0030] The results show that: Mg-Al-DTPA LDH has a good adsorption effect on Pb pollution in the solution, such as figure 2 As shown, its adsorption isotherm conforms to Freundlich adsorption i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com