Polymerization system for atom transfer radical polymerization (ATRP) using activators generated by electron transfer (AGET)

An electron transfer and atom transfer technology, applied in the field of atom transfer radical polymerization, can solve the problems of large difference between theoretical molecular weight and actual molecular weight of polymerization reaction rate, low catalytic activity, etc., to facilitate industrial production, improve polymerization rate, and reduce toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Synthesis of polystyrene (PS) with TBABr as a ligand (add alkali)

[0040] According to the ratio n(St): n(PEBr): n(FeCl 3 .6H 2 O):n(TBABr):n(VC):n(NaOH)=250:1:1~3:1~6:2:1~3, add FeCl in turn 3 .6H 2 O, TBABr, NaOH, St (2 mL), PEBr, and VC were placed in a 5 mL ampoule. After nitrogen was introduced for 15 minutes, the tube was sealed under an oxygen-free atmosphere (bulk polymerization). Place the sealed ampoule in an oil bath at a constant temperature (110°C) for a predetermined time to react. After the reaction is over, take out the sealed tube, immediately cool it with cold water, open the sealed tube, dissolve it with 2~5mL of tetrahydrofuran, pour it into 250mL of methanol, leave it overnight, suction filtration, wash with water, and dry to obtain "active" polymer. Styrene.

Embodiment 2

[0041] Example 2: Synthesis of polystyrene (PS) with TBABr as a ligand (no alkali added)

[0042] According to the ratio n(St): n(PEBr): n(FeCl 3 .6H 2 O): n(TBABr): n(VC)=250:1:1~3:1~6∶2, add FeCl in turn 3 .6H 2 O, TBABr, St (2 mL), PEBr, and VC were placed in a 5 mL ampoule, and the tube was sealed under an oxygen-free atmosphere (bulk polymerization) after nitrogen gas was introduced for 15 minutes. Place the sealed ampoule in an oil bath at a constant temperature (110°C) for a predetermined time to react. After the reaction is over, take out the sealed tube, immediately cool it with cold water, open the sealed tube, dissolve it with 2~5mL of tetrahydrofuran, pour it into 250mL of methanol, leave it overnight, suction filtration, wash with water, and dry to obtain "active" polymer. Styrene.

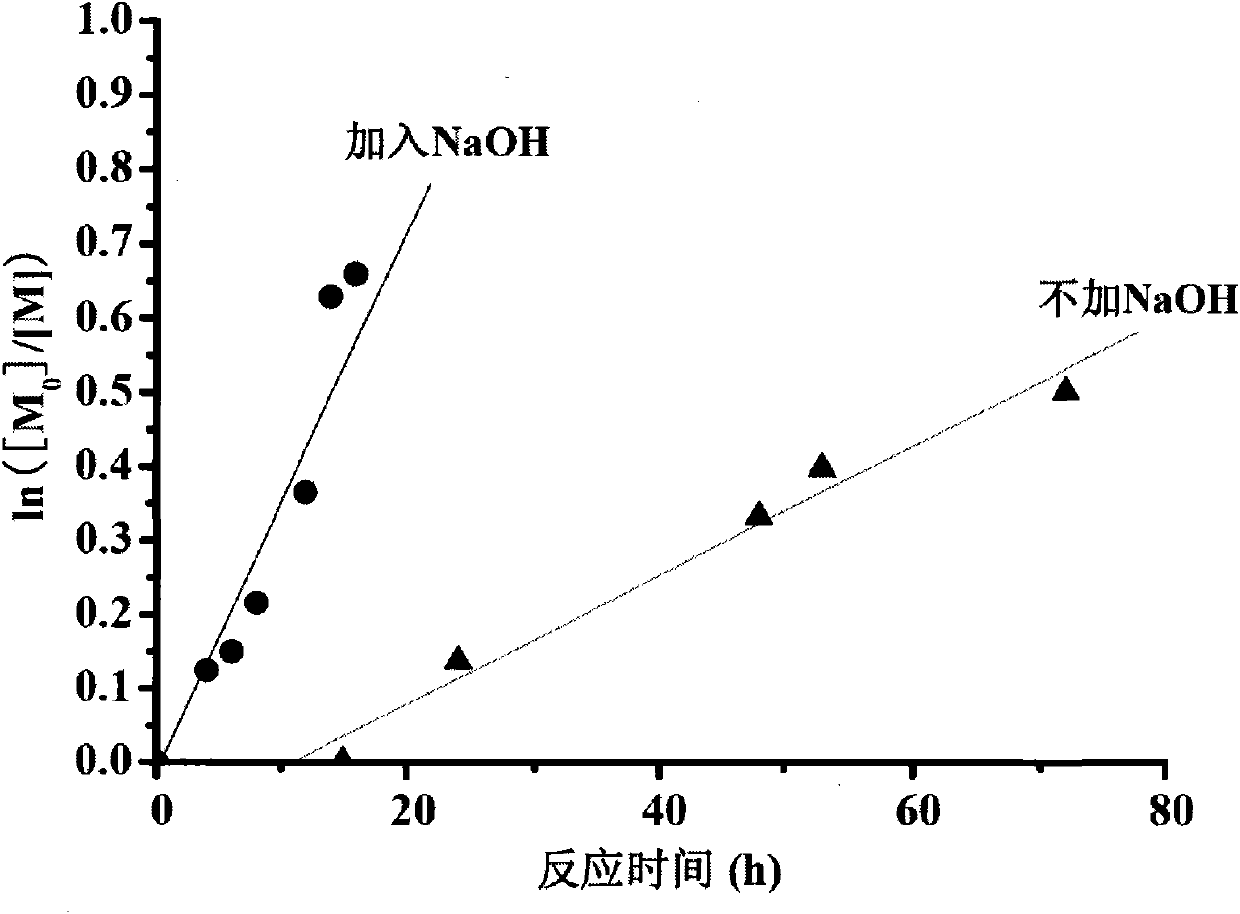

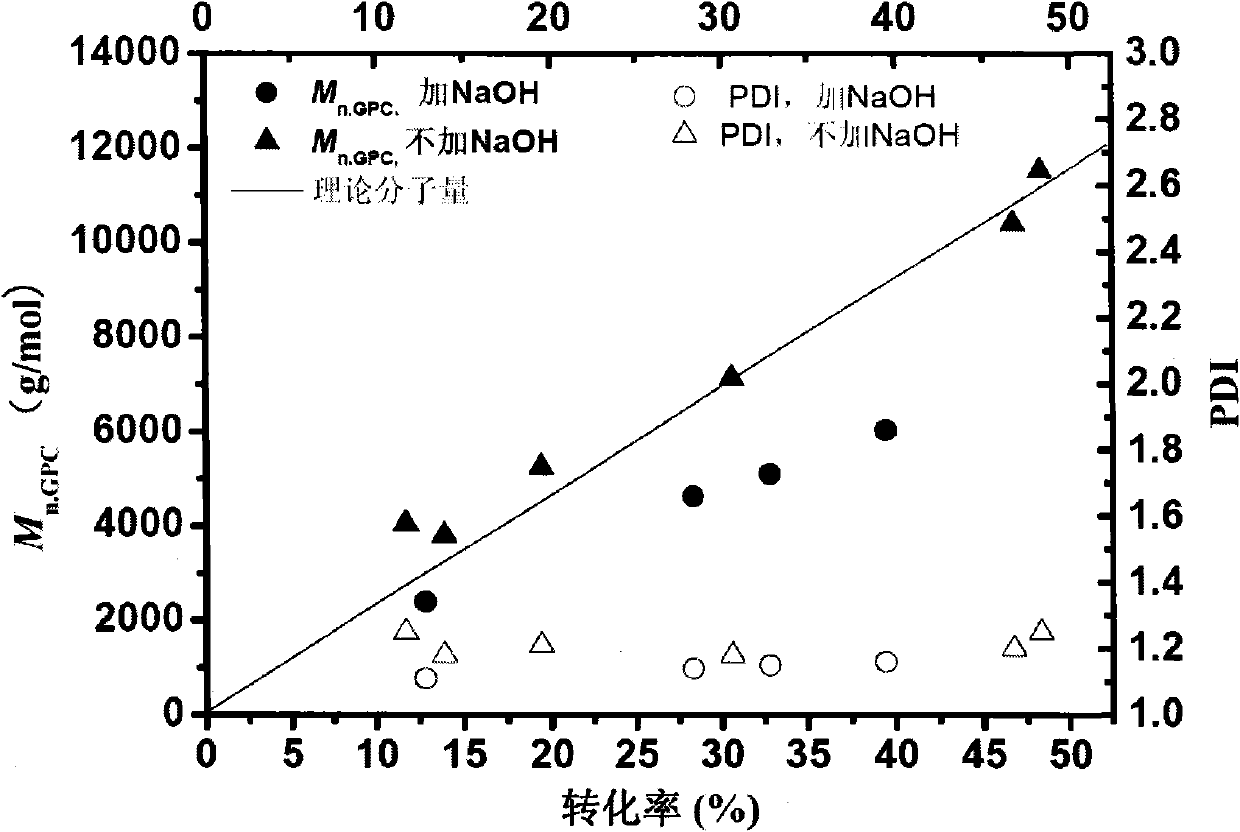

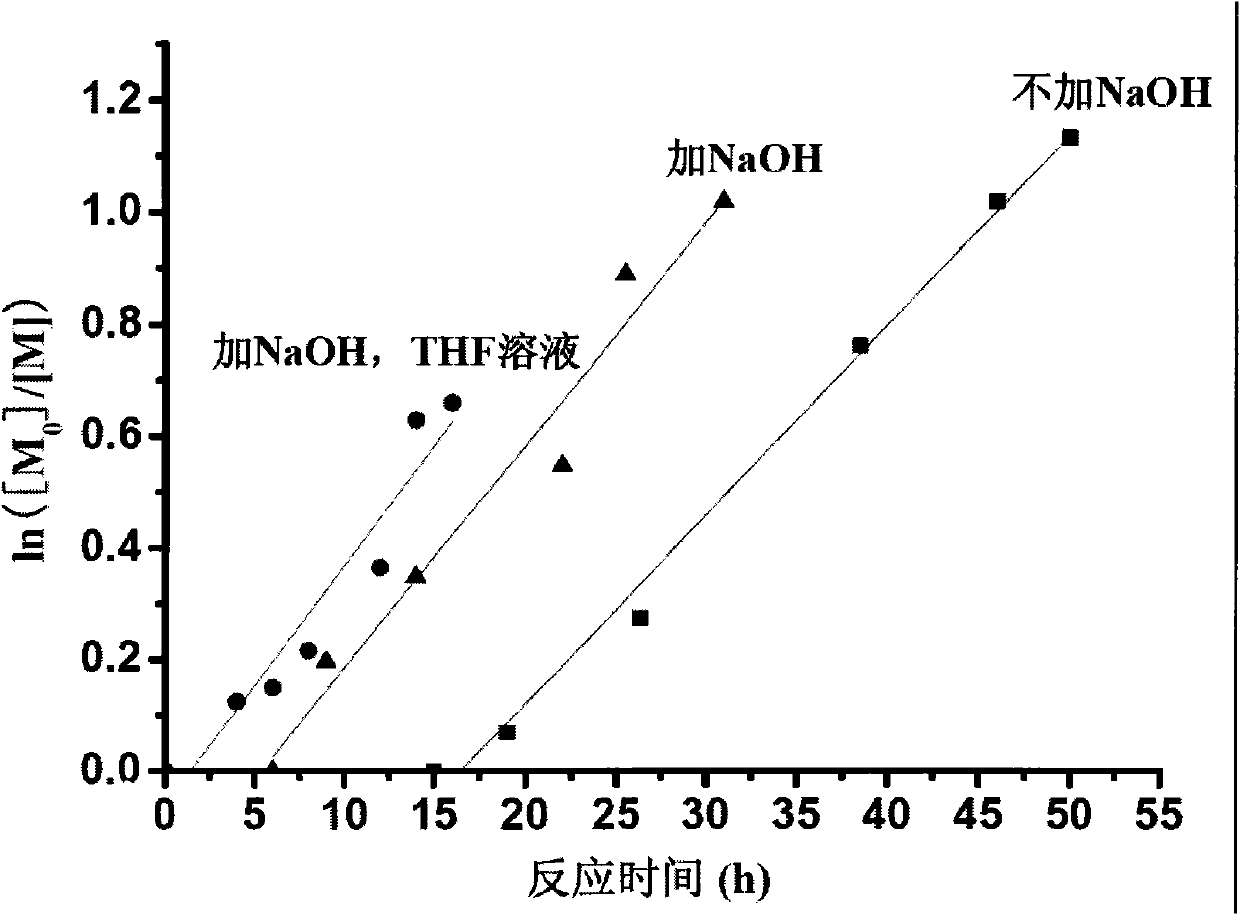

[0043] figure 1 The AGET ATRP reaction kinetics (comparison with or without alkali) of styrene catalyzed by the iron salt of TBABr as the ligand in Example 1 and Example 2.

[0044] Polyme...

Embodiment 3

[0048] Example 3: Synthesis of PS prepared with TBPBr as ligand (add alkali, add THF)

[0049] According to the ratio n(St): n(PEBr): n(FeCl 3 .6H 2 O):n(TBPBr):n(VC):n(NaOH)=250:1:1:2:2:2, add FeCl in turn 3 .6H 2 O, TBABr, NaOH, St (2 mL), PEBr, and VC were placed in a 5 mL ampoule. After nitrogen was introduced for 15 minutes, the tube was sealed under an oxygen-free atmosphere (bulk polymerization). Solution polymerization: Add 2mL THF to the system and vent the oxygen with nitrogen, then seal the tube for solution polymerization. Place the sealed ampoule in an oil bath at a constant temperature (110°C) for a predetermined time to react. After the reaction is over, take out the sealed tube, immediately cool it with cold water, open the sealed tube, dissolve it with 2-5ml of tetrahydrofuran, pour it into 250mL of methanol overnight, and then filter, wash with water and dry to obtain "active" polystyrene Vinyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com