Method for preparing graphene oxide-alumina composite aerogel

A composite aerogel and graphene technology, applied in aerogel preparation, chemical instruments and methods, colloidal chemistry, etc., can solve the problems of small specific surface area, easy agglomeration of alumina, and achieve rich pore structure and excellent electrical conductivity. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

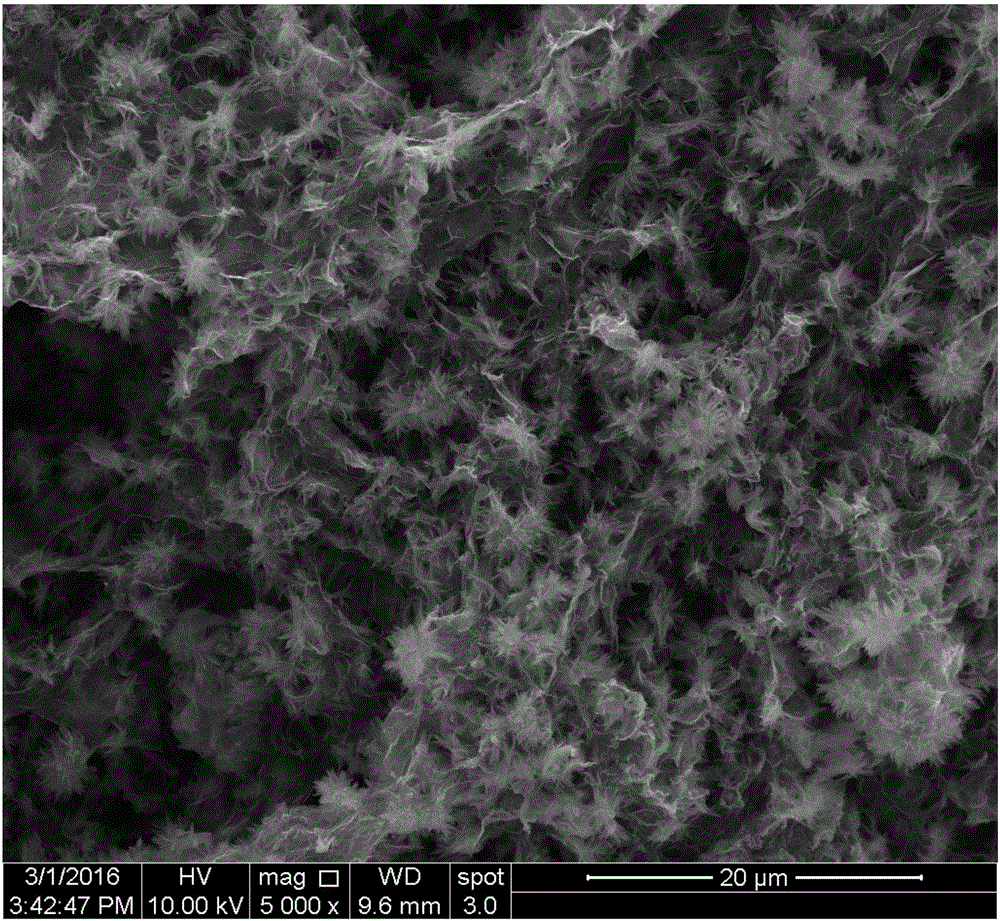

[0022] A method for preparing graphene oxide-alumina composite aerogel, using graphene oxide as a raw material to ultrasonically disperse in a solvent, adding a certain amount of aluminum chloride hexahydrate, stirring and refluxing for a certain time at a set temperature, and finally water The cylindrical wet gel is synthesized by thermal method, and after alcohol washing, water washing, and freeze-drying, the ultra-light graphene oxide-alumina composite aerogel is obtained, which specifically includes the following steps:

[0023] Step 1. Take the graphene oxide prepared by the modified Hummer method, add it to the dispersion solvent, sonicate it in an ultrasonic cleaner with 180W ultrasonic power for 1 hour, and separate it with a low-speed centrifuge at a rotation speed of 1000-8000 rpm / min. Filter out the precipitation of the lower layer and take the upper layer solution;

[0024] Wherein, the mass-volume ratio of graphene oxide to the dispersion solvent is 0.3:100˜0.2:50 g / mL...

Embodiment 1

[0031] Step 1. Take 0.3g of graphite oxide, add it to 100ml of distilled water, sonicate it in an ultrasonic cleaner with 180W ultrasonic power for 1h, separate with a low-speed centrifuge, filter out the lower layer of precipitation and take the upper layer solution;

[0032] Step 2. Take 50ml of the solution in Step 1, adjust the pH of the solution to 7.5 with dilute ammonia, then add 2.4143g of aluminum chloride hexahydrate, and react at 80°C for 4 hours;

[0033] Step 3. After the reaction in step 2 is completed, cool to room temperature, magnetically stir for 0.5h, transfer the mixed solution into a PTFE hydrothermal kettle, keep it at 180℃ for 12h, and take out the cylindrical product after the reaction kettle is down to room temperature , Wash with alcohol and water for two to three times, and dry the product in a freeze dryer for 12 hours to obtain the graphene oxide-alumina aerogel composite material.

Embodiment 2

[0035] Step 1. Take 0.2g of graphite oxide, add it to 50ml of water, sonicate it in an ultrasonic cleaner with 180W ultrasonic power for 1h, separate with a low-speed centrifuge, filter out the lower layer of precipitation and take the upper layer solution;

[0036] Step 2. Take 50ml of the solution in Step 1, adjust the pH of the solution to 6 with dilute ammonia, then add 1.2072g of aluminum chloride hexahydrate, and react at 100°C for 5 hours;

[0037] Step 3. After the reaction in step 2 is completed, cool to room temperature, magnetically stir for 0.5h, transfer the mixed solution into a PTFE hydrothermal kettle, keep it at 180℃ for 12h, and take out the cylindrical product after the reaction kettle is down to room temperature , Wash with alcohol and water for two to three times, and dry the product in a freeze dryer for 12 hours to obtain the graphene oxide-alumina aerogel composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com