Electric memory device based on one-dimensional organic/inorganic hybridized polymer chain and preparation method thereof

A polymer chain and electricity storage technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of complex preparation process, poor environment and high temperature stability, etc., and achieve simple preparation method and stable electrical energy , The effect of maintaining a constant evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

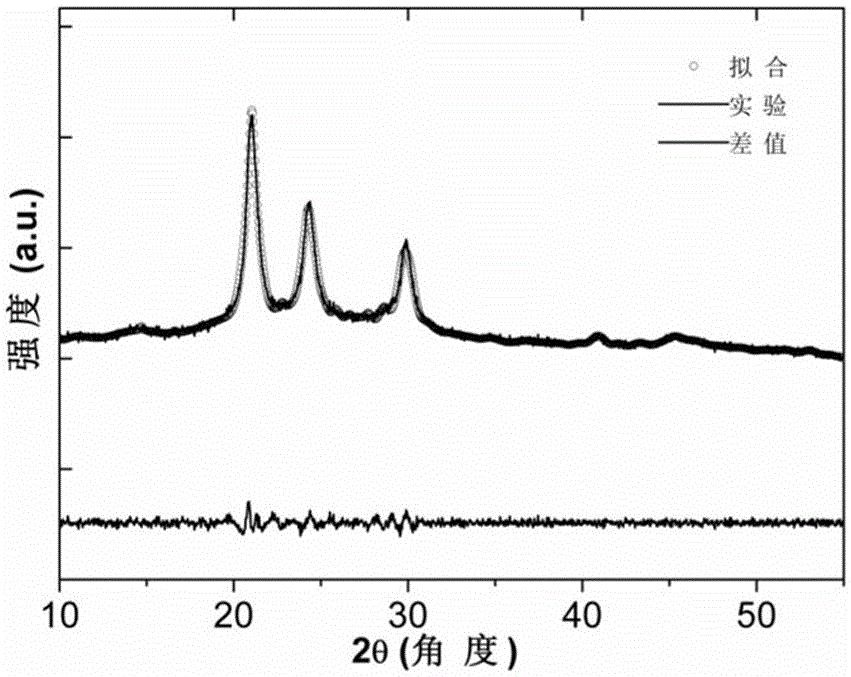

[0032] A preparation method of an organic-inorganic hybrid polymer, the specific synthesis steps are as follows:

[0033] 1,2,4,5-Phenyltetramine tetrahydrochloride (2.84 g, 10 mmol) was dissolved in DMF (50 mL), nickel dichloride hexahydrate (2.38 g, 10 mmol) was dissolved in deionized water (50 mL), and added dropwise to the above solution in an ice-water bath. Then the reaction system was adjusted to neutrality (pH = 7) by adding ammonia water dropwise. Finally, it was stirred at room temperature for 6 h. After the reaction, a black solid is formed. Centrifuge and filter to remove the solvent in the system, then add deionized water and acetone to wash the product in an ultrasonic cleaner, and remove the solvent by centrifuging and filtering. After repeating the above steps three times, the The product was placed in a vacuum drying oven and dried for 40 hours at 70°C to finally obtain a black powdery product, which was denoted as TAP;

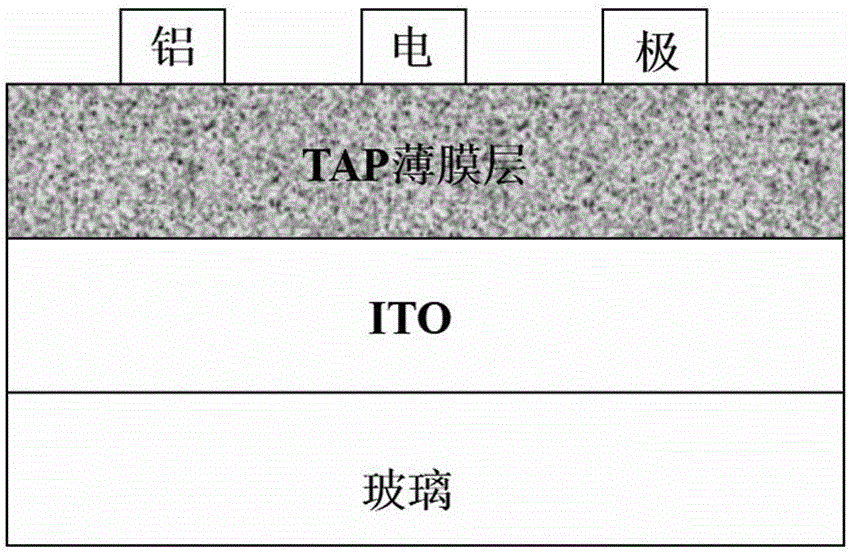

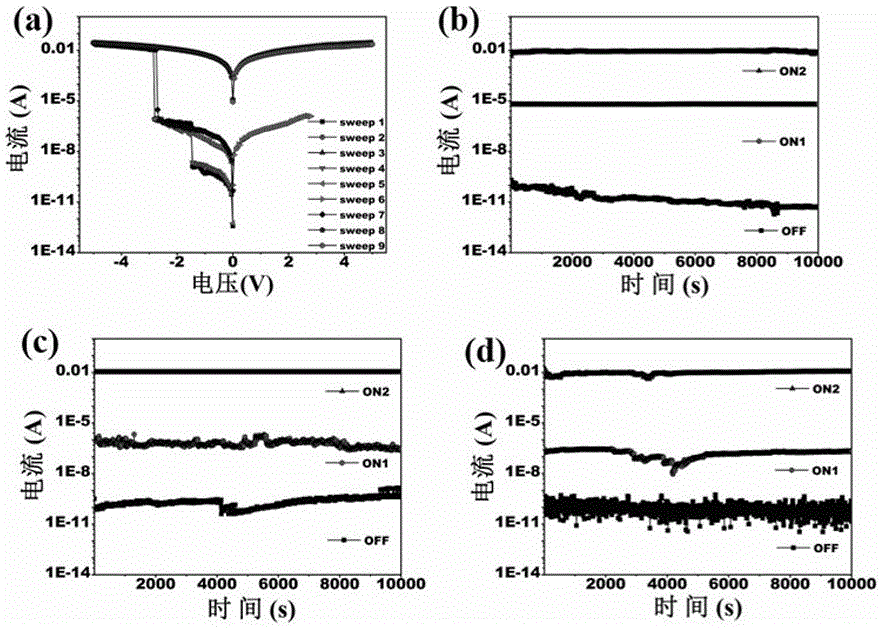

[0034] electrical storage devices s...

Embodiment 2

[0042] A preparation method of an organic-inorganic hybrid polymer, the specific synthesis steps are as follows:

[0043] 1,2,4,5-Phenyltetramine tetrahydrochloride (2.84 g, 10 mmol) was dissolved in DMF (50 mL), nickel dichloride hexahydrate (2.38 g, 10 mmol) was dissolved in deionized water (50 mL), and added dropwise to the above solution in an ice-water bath. Then the reaction system was adjusted to neutrality (pH = 7) by adding ammonia water dropwise. Finally, it was stirred at room temperature for 6 h. After the reaction, a black solid is formed. Centrifuge and filter to remove the solvent in the system, then add deionized water and acetone to wash the product in an ultrasonic cleaner, and remove the solvent by centrifuging and filtering. After repeating the above steps three times, the The product was placed in a vacuum drying oven and dried for 40 hours at 70°C to finally obtain a black powdery product, which was denoted as TAP;

[0044] A method for preparing an el...

Embodiment 3

[0051] A preparation method of an organic-inorganic hybrid polymer, the specific synthesis steps are as follows:

[0052] 3,3'-Diaminobenzidine tetrahydrochloride (3.60 g, 10 mmol) was dissolved in DMF (50 mL), nickel dichloride hexahydrate (2.38 g, 10 mmol) was dissolved in deionized water (50 mL), and added dropwise to the above solution in an ice-water bath. Then the reaction system was adjusted to neutrality (pH = 7) by adding ammonia water dropwise. Finally, it was stirred at room temperature for 6 h. After the reaction, a black solid is formed. Centrifuge and filter to remove the solvent in the system, then add deionized water and acetone to wash the product in an ultrasonic cleaner, and remove the solvent by centrifuging and filtering. After repeating the above steps three times, the The product was put into a vacuum drying oven and dried at 70°C for 40 hours to finally obtain a black powdery product, which was denoted as BPA.

[0053] A method for preparing an elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com