Preparation of composite double microporous material

A technology of microporous materials and composite molecular sieves, which is applied in the field of preparation of double microporous molecular sieves, can solve the problems of poor catalyst reactivity, no significant improvement in medium oil selectivity, and no significant improvement in catalyst activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

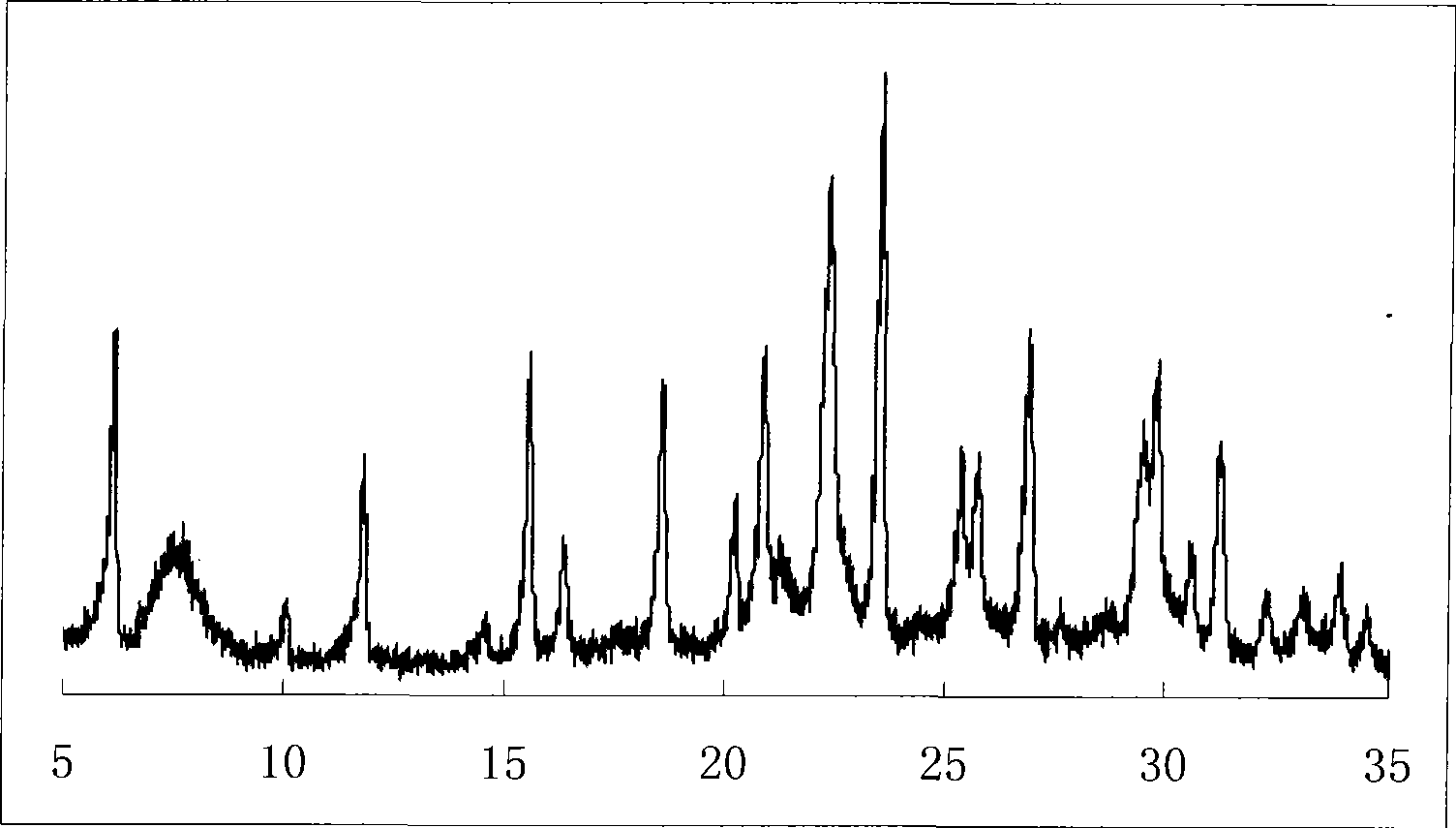

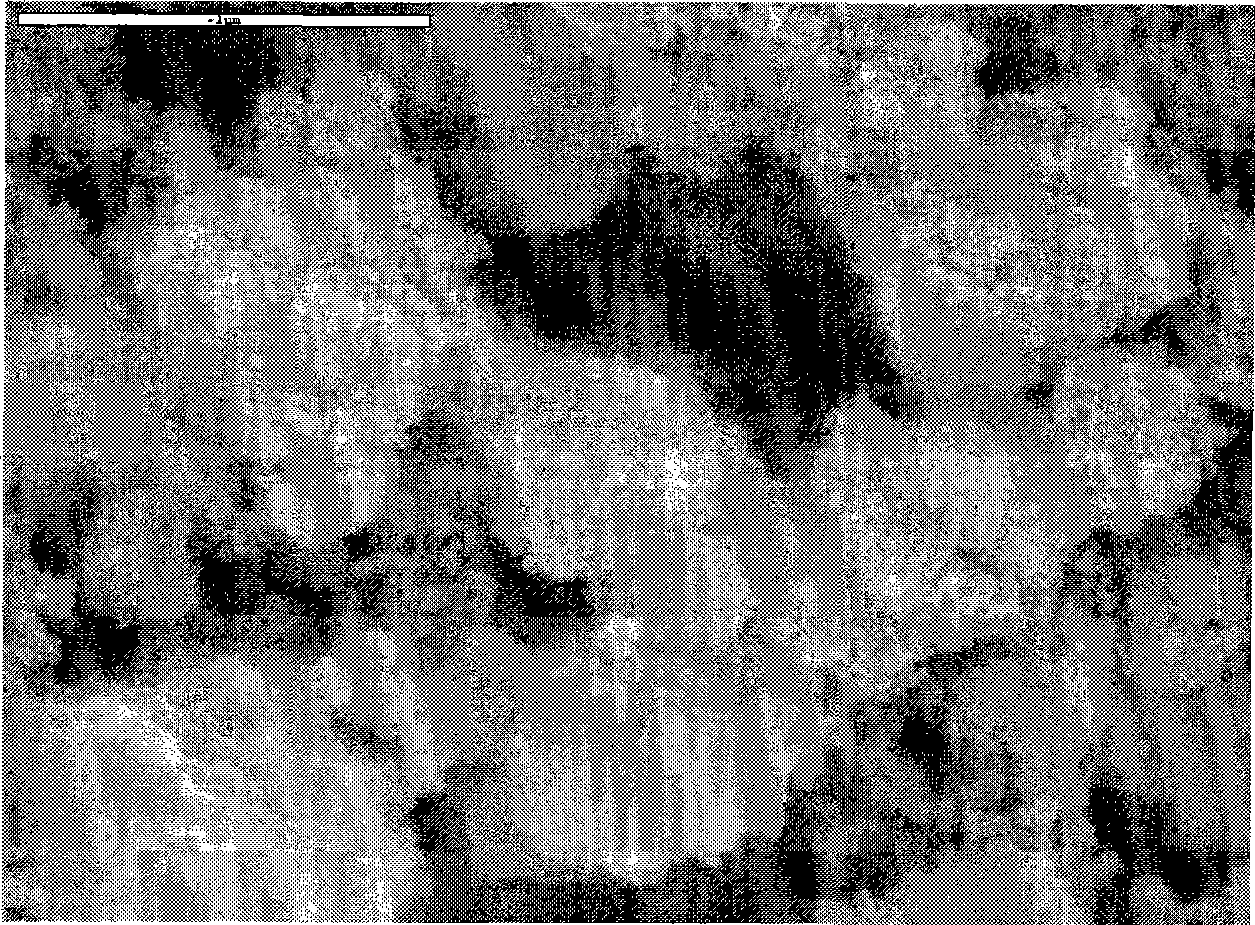

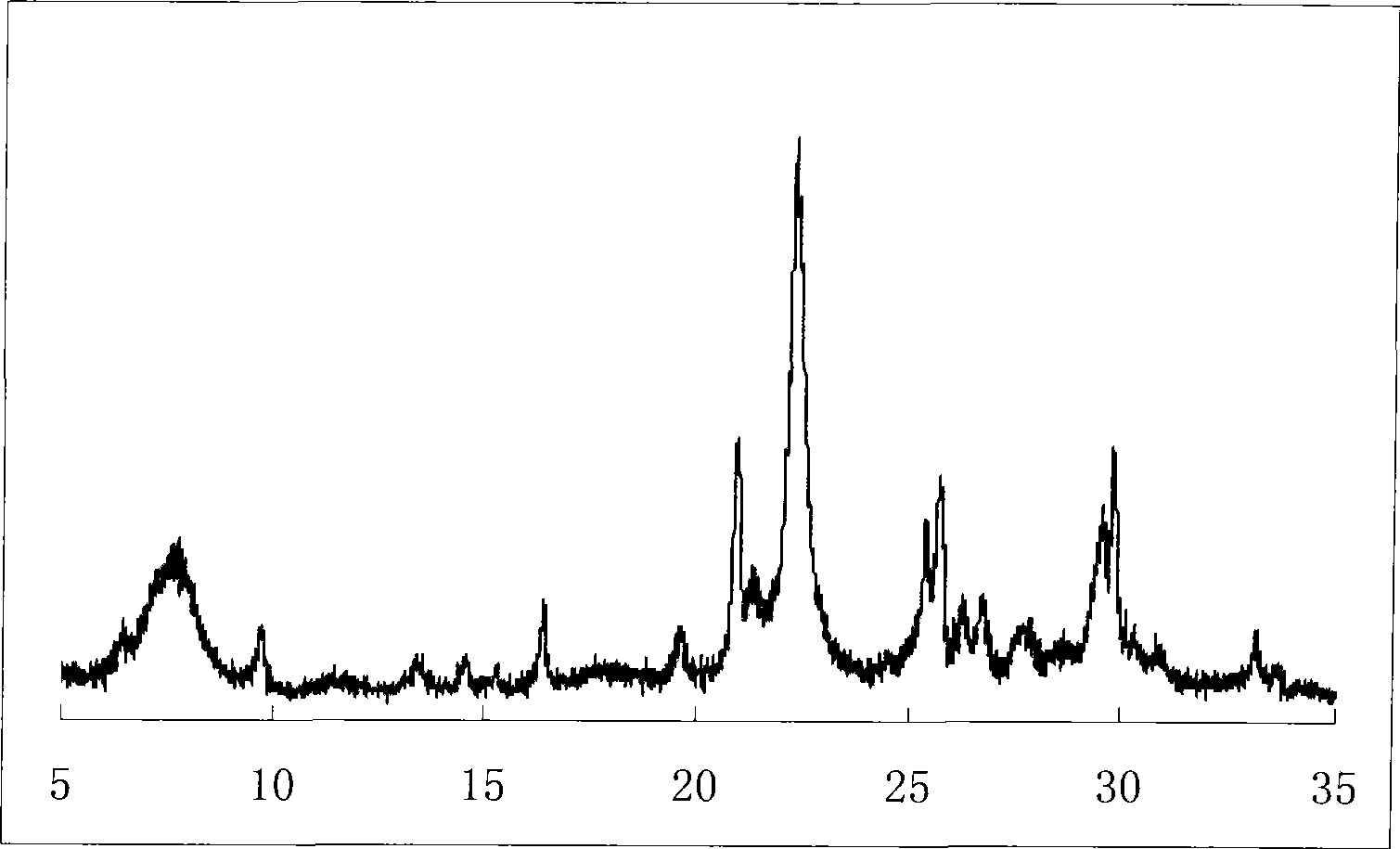

Image

Examples

preparation example Construction

[0024] (2) The preparation of silica-alumina gel can specifically take the following method: silicon source, aluminum source, sodium hydroxide, templating agent and water are mixed according to (5-35) SiO 2 :Al 2 o 3 : (3 ~ 12) R2: (1 ~ 4) Na 2 O: (100~800)H 2 The molar ratio of O is mixed at room temperature and under mechanical stirring conditions, and the stirring is continued until the raw materials are evenly mixed to obtain a silica-alumina gel; the silicon source is white carbon black, water glass or silica sol; the aluminum source is sodium aluminate or aluminum hydroxide, preferably sodium aluminate. Said templating agent R2 is tetraethylammonium bromide or tetraethylammonium hydroxide or a mixture of both.

[0025](3) Add the directing agent prepared in step (1) to the silica-alumina gel prepared in step (2), the amount of the directing agent accounts for 5v% to 20v% of the volume of the silica-alumina gel, and the reaction gel is obtained after stirring evenly. ...

Embodiment 1

[0030] (1) Preparation of guiding agent: Weigh 4.1 g of sodium hydroxide, 3.5 g of tetramethylammonium bromide and 2.1 g of sodium aluminate, dissolve in 20 ml of distilled water, and mix evenly with electromagnetic stirring. Mix the above solution with 23.5ml water glass (SiO 2 concentration of 8 mol / L), mixed with magnetic force for 0.5 hours, put into a Erlenmeyer flask, sealed and aged at 35°C for 72 hours to prepare the directing agent.

[0031] (2) The preparation of silica-alumina gel can specifically take the following method: 30g white carbon black, 7.3ml sodium aluminate solution (Al 2 o 3 Concentration is 3.4mol / L), 4g sodium hydroxide, 35g tetraethylammonium bromide and 80ml water are mixed under room temperature and mechanical stirring condition, continue to stir for 0.5 hour, obtain silica-alumina gel.

[0032] (3) Add 13.5ml of directing agent to the silica-alumina gel prepared in step (2), stir evenly to obtain a reaction gel, then add 12g NaY molecular sieve...

Embodiment 2

[0036] (1) Preparation of guiding agent: Weigh 4.1 g of sodium hydroxide, 3 g of tetramethylammonium bromide and 2.1 g of sodium aluminate, dissolve in 20 ml of distilled water, and mix well with electromagnetic stirring. Mix the above solution with 22.7ml water glass (SiO 2 concentration of 8 mol / L), mixed with magnetic force for 0.5 hours, put into a Erlenmeyer flask, sealed and aged at 35°C for 72 hours to prepare the directing agent.

[0037] (2) The preparation of silica-alumina gel can specifically take the following method: 30g white carbon black, 7.3ml sodium aluminate solution (Al 2 o 3 Concentration is 3.4mol / L), 4g sodium hydroxide, 31g tetraethylammonium bromide and 80ml water are mixed under room temperature and mechanical stirring condition, continue to stir for 0.5 hour, obtain silica-alumina gel.

[0038] (3) Add 13.5ml of directing agent to the silica-alumina gel prepared in step (2), stir evenly to obtain a reaction gel, then add 15g of NaY molecular sieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com