Preparation method of aluminum-enriched beta zeolite

A beta zeolite and aluminum-rich technology, which is applied in the field of preparation of aluminum-rich beta zeolite, can solve the problems of long crystallization time and achieve the effects of shortened crystallization time, high crystallinity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0027] The raw materials and proportioning of Examples 1-5 are shown in Table 1. First prepare the silica-alumina co-gel, age the prepared silica-alumina co-gel at 20°C-220°C for 12-48 hours, then grind it into particles smaller than 20 mesh, and continue to heat it at 400°C, 500°C, 600°C, and 800°C respectively. ℃, 1200 ℃ for treatment. Control the appropriate ratio of raw materials, add tetraethylammonium hydroxide (TEAOH), water and hydrofluoric acid, after ultrasonic dispersion or mechanical stirring, and then put in the reactor for crystallization reaction. After crystallization for the required time, take out the water to cool, filter and wash the reacted material, and dry at 120°C to obtain aluminum-rich beta zeolite. The silicon-aluminum ratio and crystallinity of the product are shown in Table 1.

[0028] In Table 1, the standard method for testing the silicon-aluminum molar ratio data of the product beta zeolite is ICP analysis (referring to Zamechek W. Determinati...

example 6~10

[0032] The raw materials and proportioning of Examples 6-10 are shown in Table 2. First prepare the silica-alumina co-gel, age the prepared silica-alumina co-gel at 20°C-220°C for 12-48 hours, then grind it into particles smaller than 20 mesh, and continue to heat it at 450°C, 550°C, 650°C, and 860°C respectively. ℃, 1150 ℃ for 24h. Control the appropriate ratio of raw materials, add a certain amount of tetraethylammonium hydroxide, water and hydrofluoric acid, and disperse evenly through ultrasonic dispersion or mechanical stirring. Then put it in a reaction kettle for crystallization reaction, and the reacted material is filtered and washed, and dried at 120°C to obtain aluminum-rich beta zeolite.

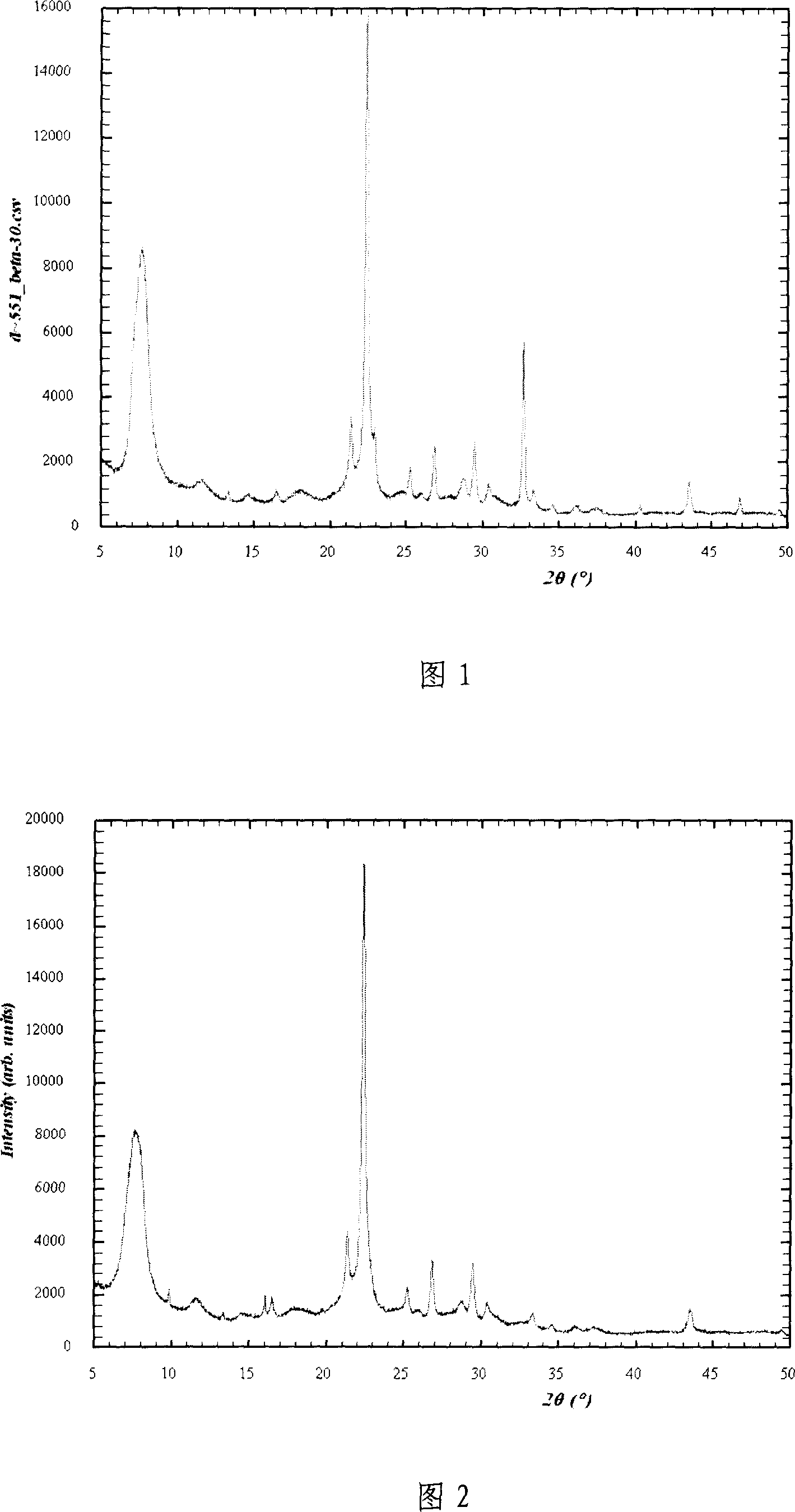

[0033] The XRD spectrogram features of the samples of Examples 6-10 are the same as those in accompanying drawing 2.

[0034] Table 2

[0035] Example

[0036] Compared with the standard industrial agent β30, the XRD pattern of the aluminum-rich beta zeolite prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com