SCR-based NO oxidation catalyst and preparation method thereof

An oxidation catalyst, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as narrow temperature window, achieve good stability, improve Oxidation rate, simple effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

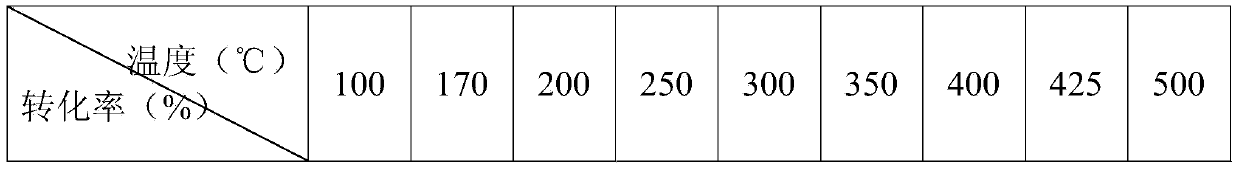

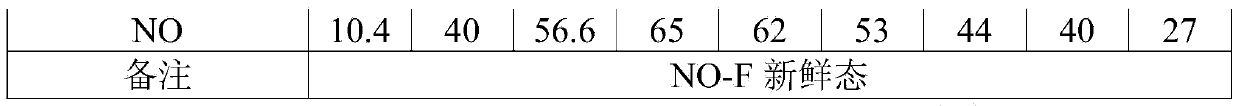

Examples

Embodiment 1

[0021] Embodiment one: a kind of preparation method of NO oxidation catalyst based on SCR, comprises the following steps:

[0022] (1) Slurry preparation: mix SiO 2 , Molecular sieve, zirconium acetate, and binder are added to deionized water, the weight ratio is 0.72:0.25:0.02:0.01, fully stirred evenly, and the measured pH is 3.24;

[0023] (2) Slurry ball mill: The slurry is ground by a planetary ball mill with a rotating speed of 250 rpm and a running time of 6 hours. The particle size of the slurry reaches D90 of 3.22um;

[0024] (3) Determination of solid content: Take 10g of the slurry in a dry pot, place the dry pot in a muffle furnace at 600°C for 10 minutes, cool to room temperature, weigh the powder mass as 3.95g, and divide the mass by 10g , the solid content of the slurry is 39.5%;

[0025] (4) Addition of noble metal Pt solution: take 1000g of the slurry after ball milling, and the amount of noble metal Pt added is 15g / ft 3 , the coating amount is 100g / L, the ...

Embodiment 2

[0031] Embodiment two: a kind of preparation method of NO oxidation catalyst based on SCR, comprises the following steps:

[0032] (1) Slurry preparation: mix SiO 2 , Molecular sieve, zirconium acetate, and aluminum glue binder are added to deionized water, the weight ratio is 0.58:0.35:0.04:0.03, fully stirred evenly, and the measured pH is 3.29;

[0033] (2) Slurry ball mill: The slurry is ground by a planetary ball mill with a rotating speed of 320 rpm and a running time of 4 hours. The particle size of the slurry reaches D90 of 3.16um;

[0034] (3) Determination of solid content: Take 10g of slurry in a dry pot, place the dry pot in a muffle furnace at 600°C for 10 minutes, cool to room temperature, weigh the powder mass as 3.89g, divide the mass by 10g , the solid content of the slurry is 38.9%;

[0035] (4) Addition of precious metal solution Pt: take 1000g of ball milled slurry, and the amount of precious metal Pt added is 20g / ft 3 , the coating amount is 140g / L, the...

Embodiment 3

[0041] Embodiment three: a kind of preparation method of NO oxidation catalyst based on SCR, comprises the following steps:

[0042] (1) Slurry preparation: mix SiO 2 , Molecular sieve, zirconium acetate, and aluminum adhesive are added to deionized water with a weight ratio of 0.4:0.45:0.1:0.05, fully stirred evenly, and the measured pH is 3.45;

[0043] (2) Slurry ball mill: The slurry is ground by a planetary ball mill with a rotating speed of 380 rpm and a running time of 3 hours. The particle size of the slurry reaches D90 of 3.08um;

[0044] (3) Determination of solid content: Take 10g of the slurry in a dry pot, place the dry pot in a muffle furnace at 580°C and roast for 20min, cool to room temperature, weigh the powder mass as 3.97g, divide the mass by 10g , the solid content of the slurry is 39.7%;

[0045] (4) Addition of precious metal Pt solution: take 1000g of ball-milled slurry, and the amount of precious metal Pt added is 30g / ft 3 Calculation, the coating am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com