Composite submerged nozzle and manufacturing method thereof

A manufacturing method and immersion technology, applied in the direction of manufacturing tools, casting equipment, casting melt containers, etc., can solve the problems of low strength, low thermal conductivity, etc., achieve high thermal shock resistance, improve quality, and prevent impurities from adhering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

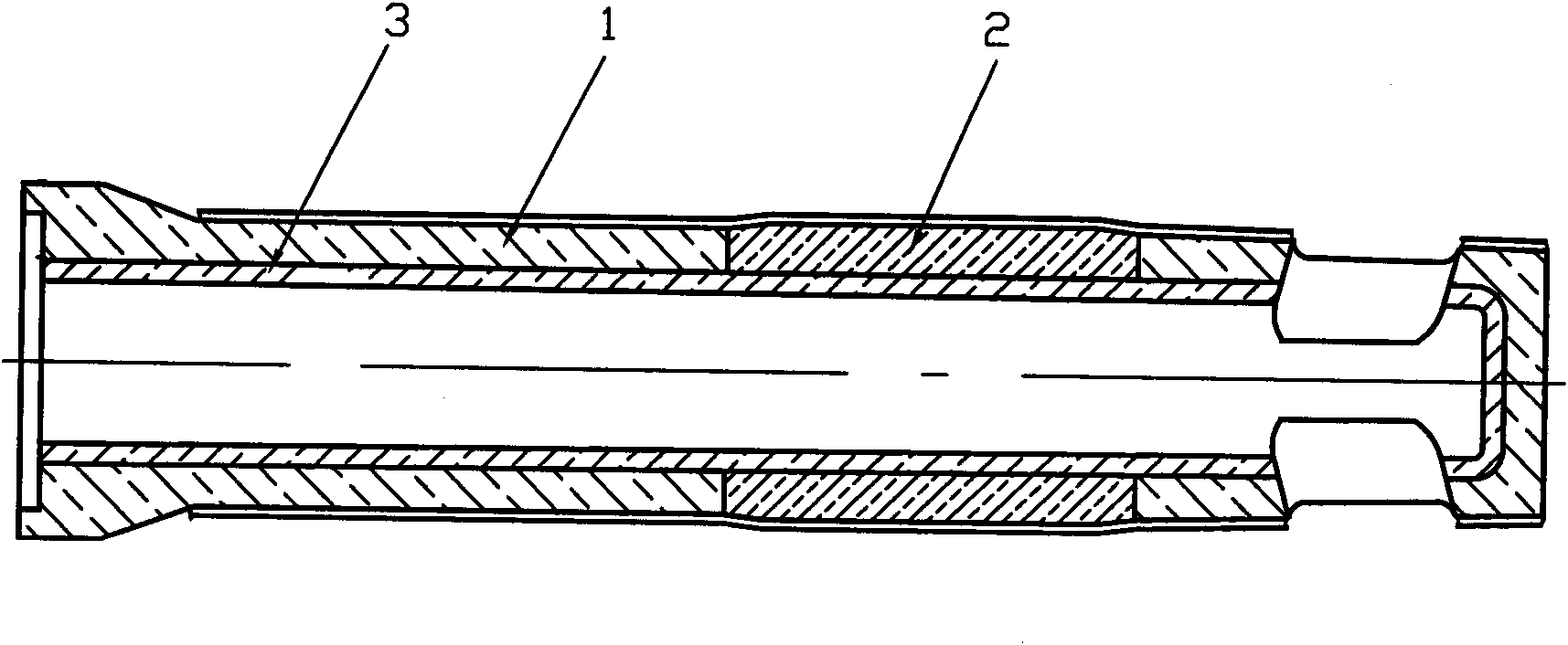

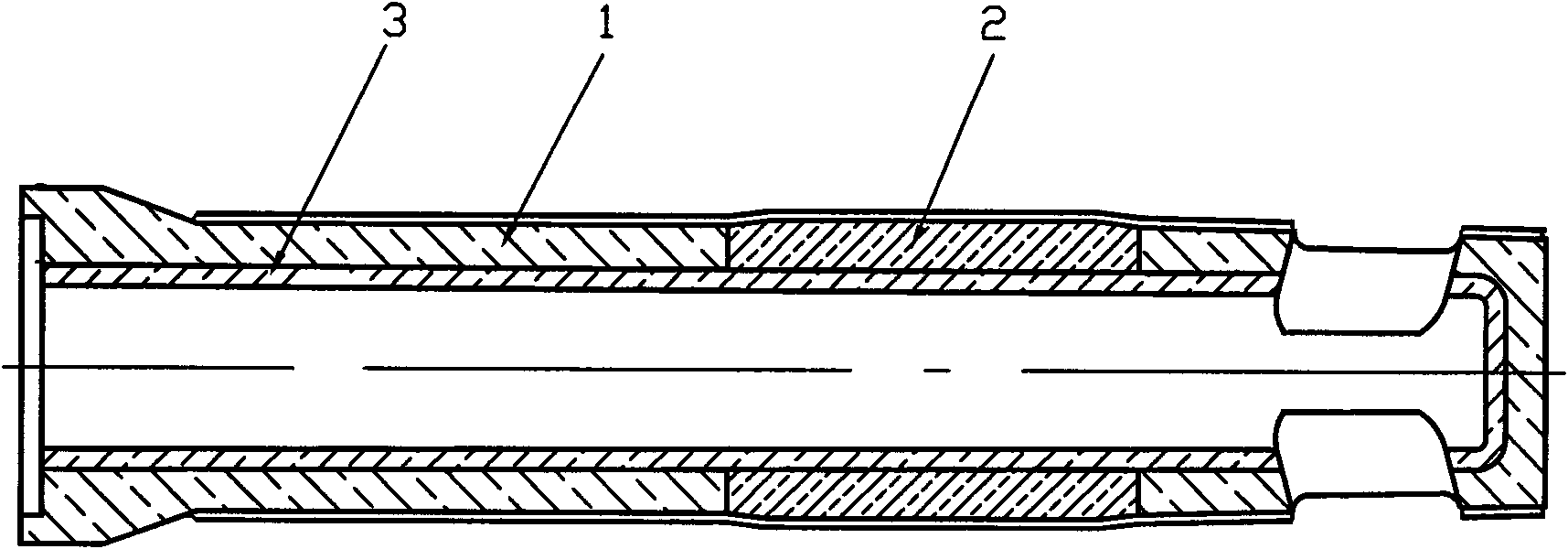

[0025] see figure 1 , which shows the composite submerged nozzle of the present invention, which includes an outer body 1 , an outer slag segment 2 and an inner layer 3 .

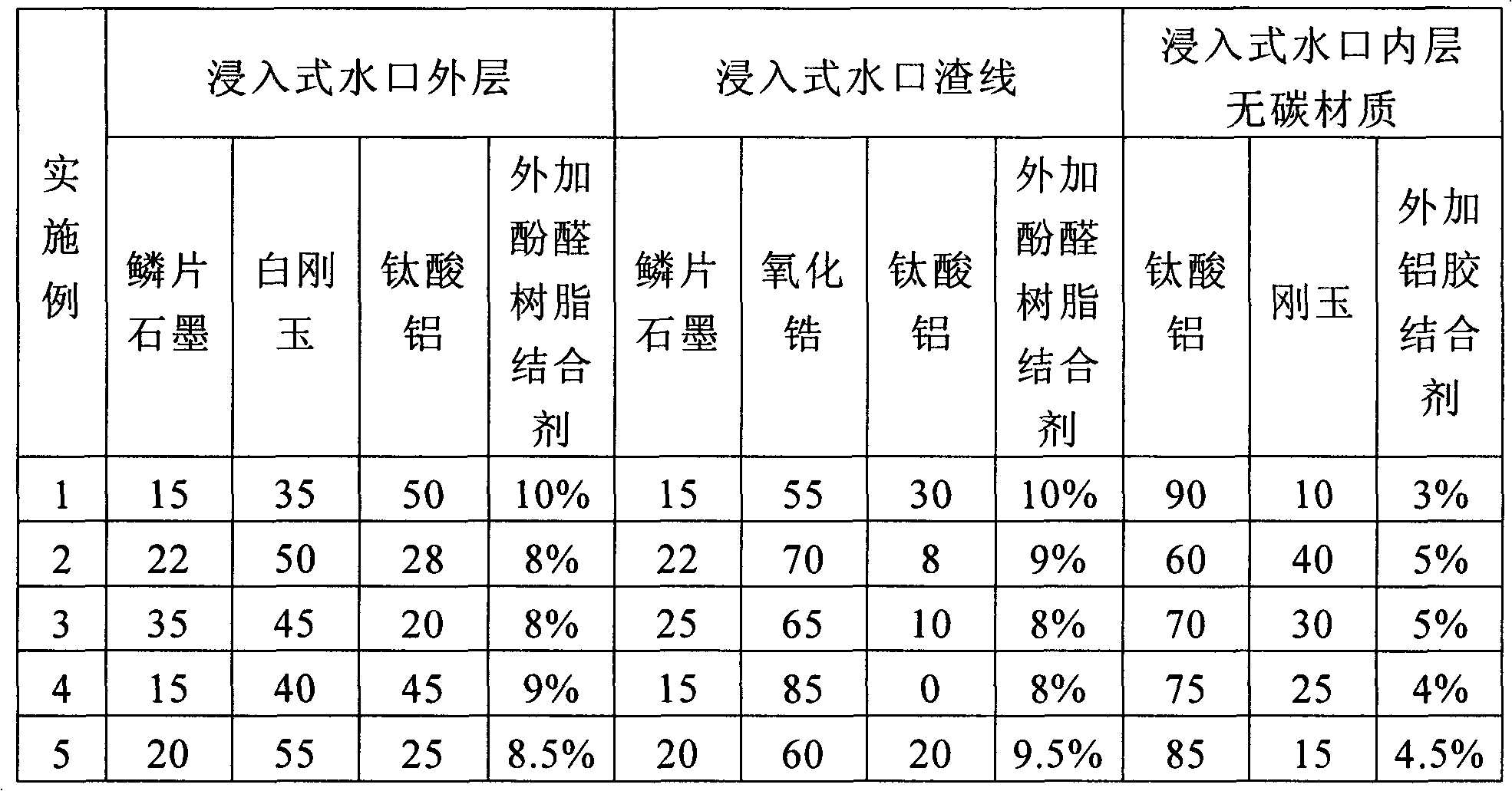

[0026] The manufacturing method of the composite submerged nozzle of the present invention comprises the following steps: 1) the composite submerged nozzle, including the outer layer body, the outer layer slag line section and the inner layer; the composition ratio plug-in of the specific embodiment; 2) according to the proportioning, Mix the material of the outer body, the slag line material of the outer layer and the material of the inner layer evenly, add 8-10% of the phenolic resin binder when adding the above components to the outer layer material, and use a granulator to granulate the raw materials. The granulated material is dried on the drying bed to make it meet the molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com