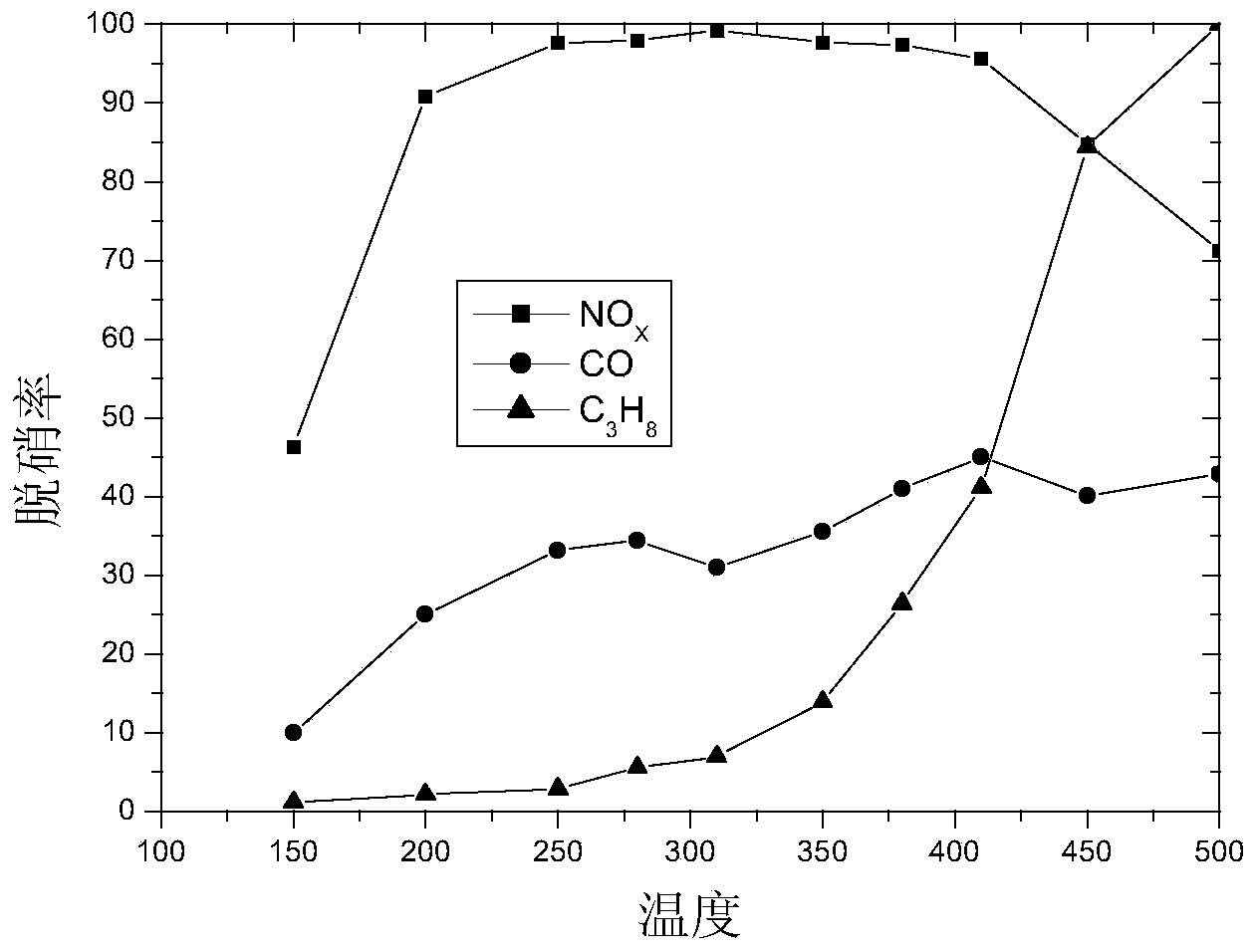

Three-way NOx, CO and HC removing catalyst used in marine engine, and preparation method thereof

A catalyst and co-catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve difficult removal of CO, complex preparation process, high cost, etc. problems, to achieve the effect of good thermal stability, simple preparation process, and excellent shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of cerium-tin-tungsten composite ion solution

[0028] With the molar ratio of Ce / Sn / W as 1:0.4:0.8, weigh 2.5g of cerium nitrate, 0.81g of tin tetrachloride, and 1.31g of ammonium metatungstate, respectively, and dissolve them in a nitric acid solution with a mass concentration of 15%. In, a stable cerium-tin-tungsten saturated solution was prepared evenly by stirring;

[0029] (2) Preparation of cocatalyst precursor ion solution

[0030] Screen and weigh 0.08g cobalt nitrate, dissolve it in water, and prepare a uniform and stable saturated solution through stirring;

[0031] (3) Al-Si-Ti composite oxide precursor pretreatment

[0032]With the molar ratio of Al / Si / Ti as 1:0.05:50, weigh 0.23g of diaspore, 0.01g of clay, and 19.73g of titanium dioxide, and add 0.02g of diaspore into 0.35g of 50% nitric acid solution Prepare acidic aluminum sol, dry mix the remaining diaspore with clay and titanium dioxide;

[0033] (4) Preparation and pretreatment of...

Embodiment 2

[0040] (1) Configuration of cerium-tin-tungsten composite solution

[0041] With the molar ratio of Ce / Sn / W elements being 1:0.1:0.01, weigh 2.29g of cerium nitrate, 0.113g of stannous sulfate, and 0.015g of ammonium metatungstate, respectively, and dissolve them in a sulfuric acid solution with a mass concentration of 1%. , and prepare a stable cerium-tin-tungsten compound solution by uniform stirring;

[0042] (2) Preparation of cocatalyst precursor ion solution

[0043] Screen and weigh 0.315g of silver nitrate, 0.315g of silver acetate, 0.68g of yttrium nitrate and 0.6g to be dissolved in a nitric acid solution with a mass concentration of 1%, and stir to evenly configure a stable saturated solution;

[0044] (3) Al-Si-Ti composite oxide precursor pretreatment

[0045] With the molar ratio of Al / Si / Ti as 1:0.05:50, weigh 0.242g of diaspore, 0.01g of clay, and 19.73g of titanium dioxide, and add 0.008g of diaspore into 0.7g of 10% nitric acid solution Prepare acidic alum...

Embodiment 3

[0052] (1) Preparation of cerium-tin-tungsten composite ion solution

[0053] With the molar ratio of Ce / Sn / W elements being 1:0.1:3, weigh 1.85g of cerium oxalate, 0.15g of stannous chloride, and 5.17g of ammonium tungstate, respectively, and dissolve them in a citric acid solution with a mass concentration of 15%. In, a stable cerium-tin-tungsten saturated solution was prepared evenly by stirring;

[0054] (2) Preparation of cocatalyst precursor ion solution

[0055] Screen and weigh 10.1g ferric nitrate and dissolve it in a hydrochloric acid solution with a mass concentration of 15%, and configure a stable saturated solution through uniform stirring;

[0056] (3) Al-Si-Ti composite oxide precursor pretreatment

[0057] With the molar ratio of Al / Si / Ti as 1:0.05:100, weigh 0.12g of diaspore, 0.01g of clay, and 19.87g of titanium dioxide, and add 0.06g of diaspore into 0.57g of 50% hydrochloric acid solution Prepare acidic aluminum sol, dry mix the remaining diaspore with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com