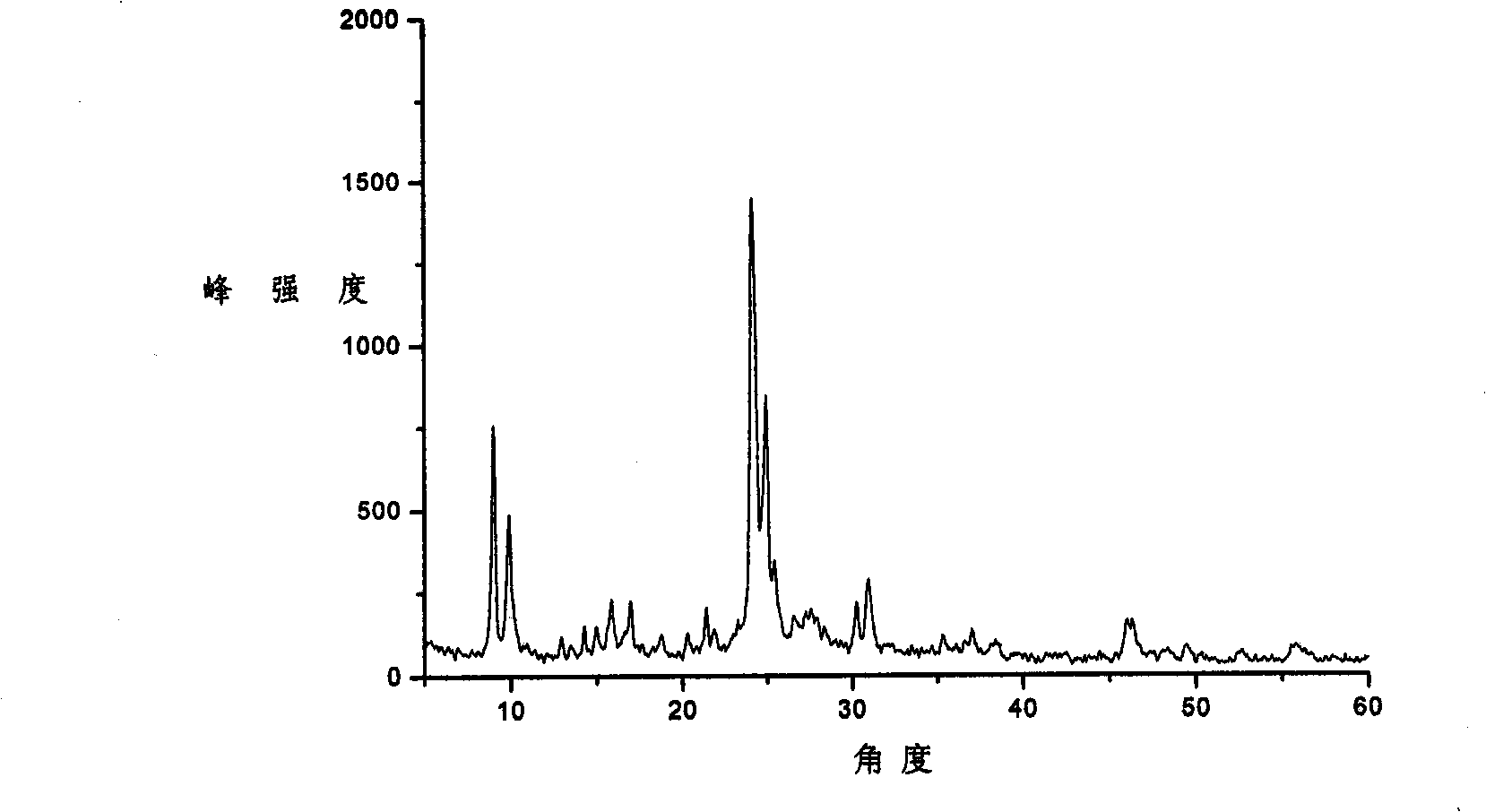

Method for preparing ZSM-5 zeolite catalyst

A zeolite catalyst, ZSM-5 technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult particle size control, achieve good reproducibility, solve difficult particle size control, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

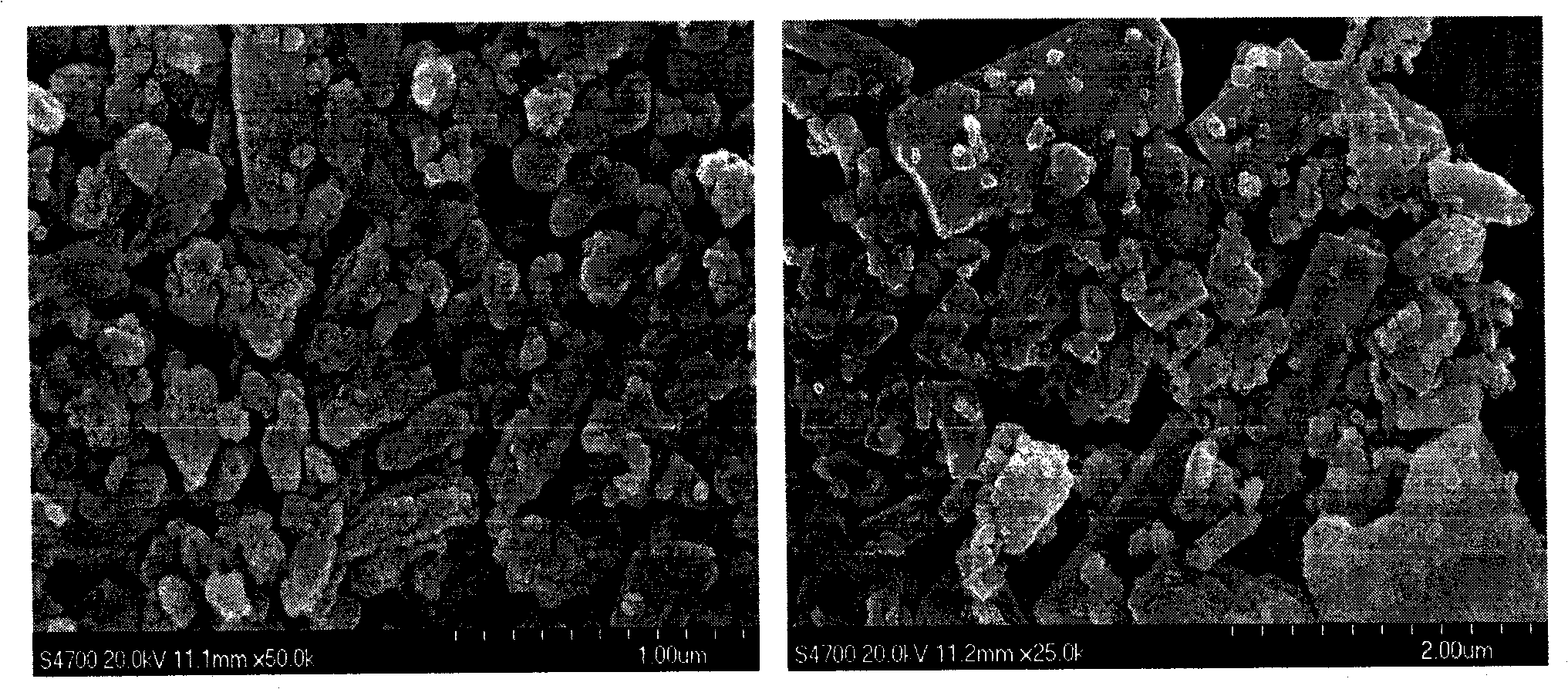

Embodiment 1

[0029] Take 60ml of water glass with a modulus of 3.1 and dilute it to 200ml with deionized water to obtain solution A;

[0030] Take 11gAl 2 (SO 4 ) 3 18H 2 O, add 50ml deionized water to prepare B solution;

[0031] Under stirring, add solution B into solution A, after stirring evenly, add 1mol L dropwise -1 Sulfuric acid, adjust the pH of the system to 6±1, put the mixture in a 60°C water bath for 15 hours, then transfer it to a 500ml reaction kettle, add 0.5g tetrabutylammonium bromide, seal it, and stir at 500rpm Conditions, aging at 120°C for 4h, and then press into the mixture above the liquid surface of CO 2 gas until the system reacts to CO 2 The absorption of gas reaches saturation, and the hydrothermal crystallization is carried out at 180°C for 36h. After the crystallization is completed, it is rapidly cooled by cooling water through the cooling coil, filtered, washed, and dried to obtain the target product. The filtrate was reserved for the next repeated u...

Embodiment 2

[0034] The filtrate that obtains in embodiment 1 is through removing Na + , SO 4 2 - treatment, use it to dilute 60ml of water glass with a modulus of 3.1 to 200ml, and make A solution;

[0035] Take 11gAl 2 (SO 4 ) 3 18H 2 O, add 50ml deionized water to prepare B solution;

[0036] Under stirring, add solution B into solution A, after stirring evenly, add 1mol L dropwise-1 The pH value of the sulfuric acid adjustment system is 6±1. Under the condition of 80°C water bath, let the mixture stand for 10h, then transfer it to a 500ml reaction kettle, add 0.5g tetrabutylammonium bromide, seal it, and stir it at 700rpm aging at 140°C for 4 hours, and then inject CO over the liquid surface of the mixture 2 gas until the system reacts to CO 2 The absorption of gas reaches saturation, and the hydrothermal crystallization is carried out at 180°C for 20h. After the crystallization is completed, the catalyst is rapidly cooled by cooling water, filtered, washed and dried to obtain...

Embodiment 3

[0040] Take 70ml of water glass with a modulus of 2.8, dilute to 200ml with the filtrate after the solid-liquid separation after the previous reaction is completed, and it is A solution;

[0041] Take 3gNaAlO 2 , add 50ml of deionized water to prepare solution B; under stirring, add solution B to solution A, after stirring evenly, add 2mol·L solution dropwise -1 Nitric acid to adjust the pH value of the system to 6±1. Under the condition of 80°C water bath, let the mixture stand for 10 hours, then transfer it to a 500ml reaction kettle, add 3.0ml ethylenediamine, seal it, and under the condition of 500rpm stirring speed, in Aging at 130°C for 8h, then press into the mixture above the liquid surface of CO 2 gas until the system reacts to CO 2 The absorption of gas reaches saturation, and the hydrothermal crystallization is carried out at 180°C for 20h. After the crystallization is completed, the catalyst is rapidly cooled by cooling water, filtered, washed and dried to obtai...

PUM

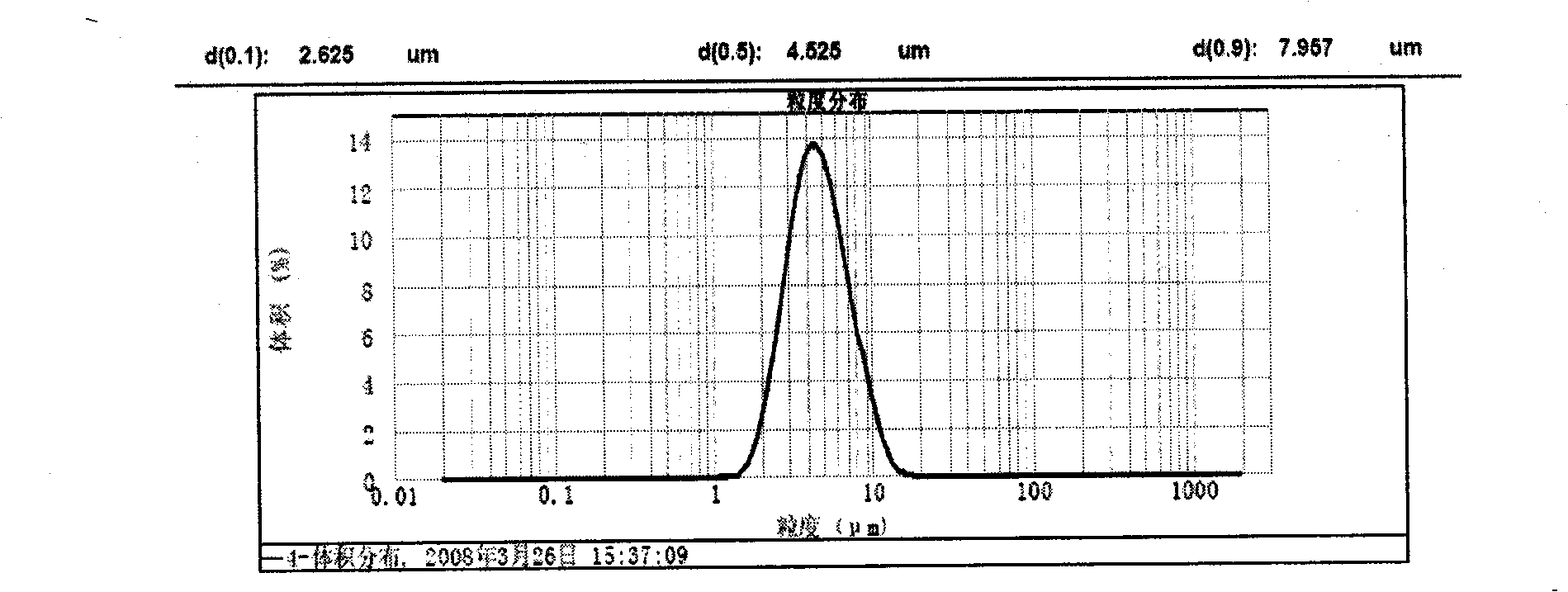

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com