Method for preparing ZSM-5 zeolite catalyst

A zeolite catalyst, ZSM-5 technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult control of particle size, achieve good reproducibility, solve difficult particle size control, The effect of easy operation

Inactive Publication Date: 2011-01-05

BEIJING UNIV OF CHEM TECH

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

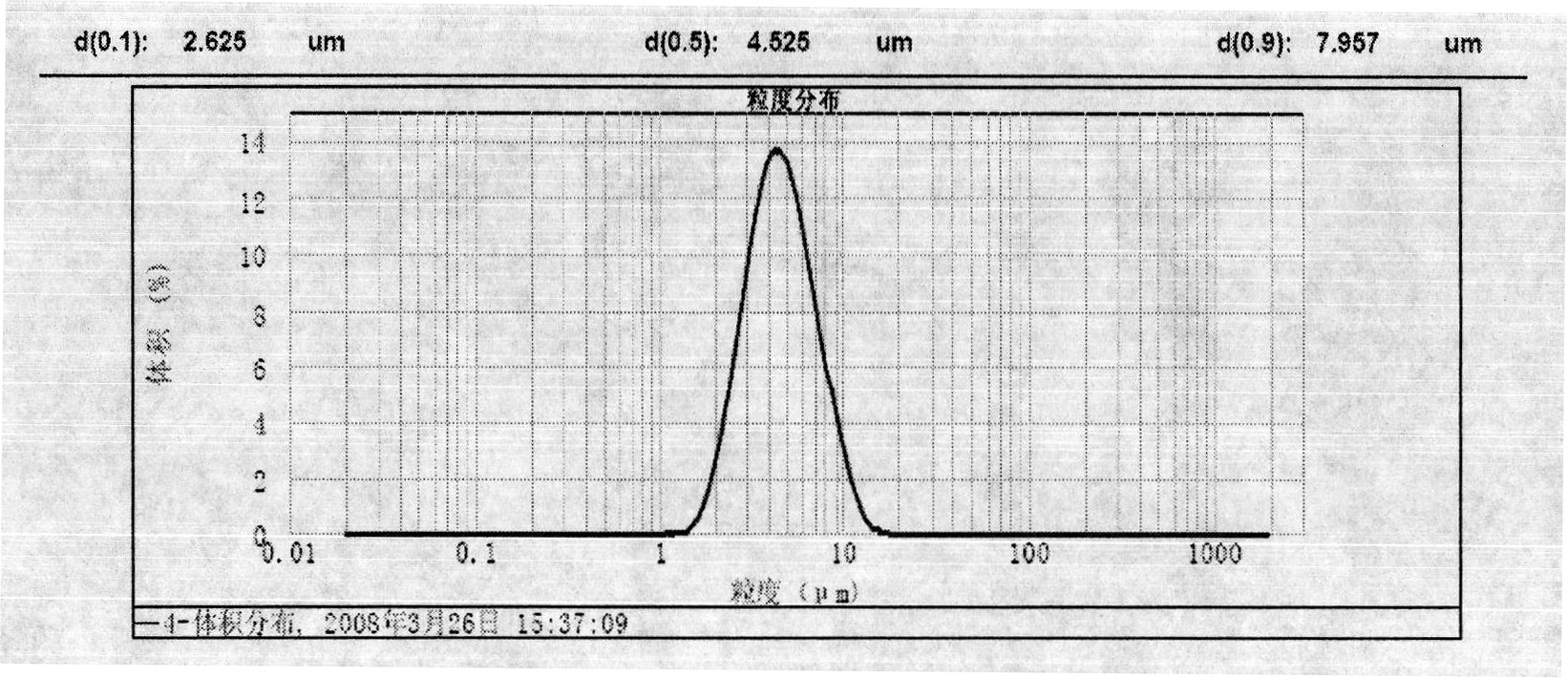

The purpose of the present invention is to provide a preparation method of ZSM-5 zeolite catalyst for the problem that the particle size is difficult to control in the preparation of ZSM-5 zeolite catalyst, and its average particle size is controlled within the range of 3-7 μm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

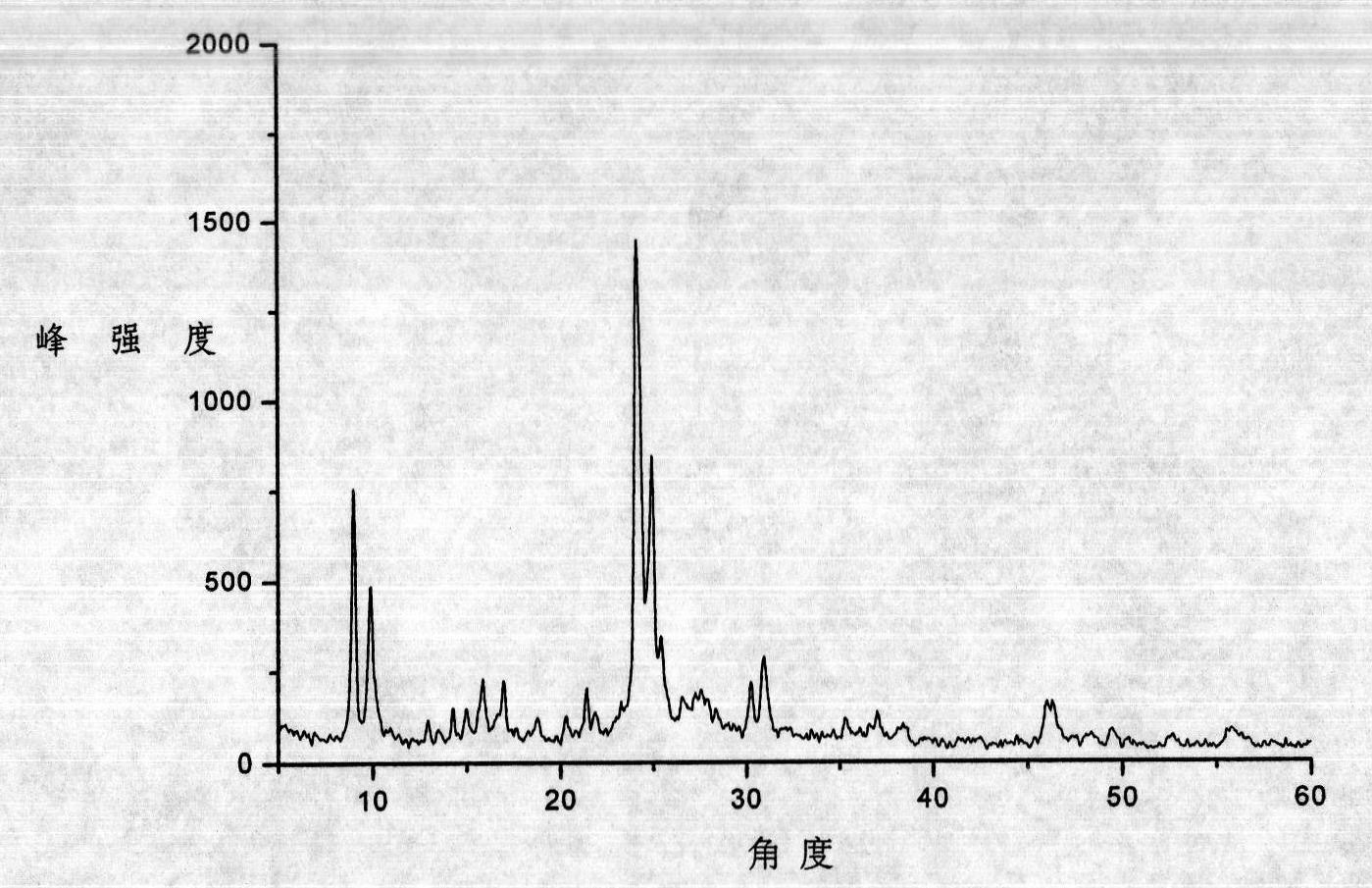

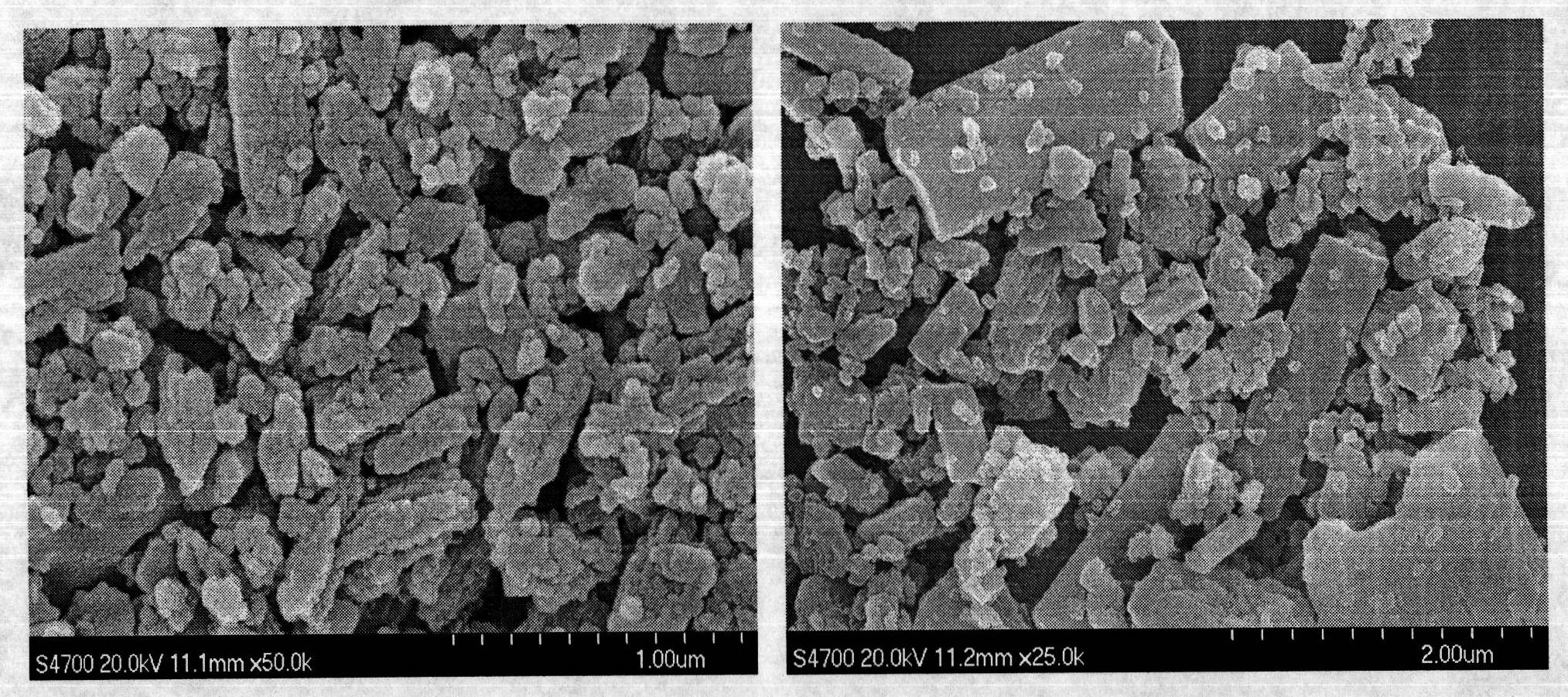

The invention discloses a method for preparing a ZSM-5 zeolite catalyst. The method comprises the following steps: mixing mixed salt solution of a silicon source and a sodium source with aluminum salt solution according to a proportion to form silica-alumina gel, adding the silica-alumina gel and a template agent into a high-temperature high-pressure reaction kettle, and carrying out hydrothermalcrystallization for the mixture under set conditions to form the ZSM-5 catalyst. The method is characterized in that during the hydrothermal crystallization, CO2 gas is introduced above the liquid level at proper time to further adjust and control the pH value of a system; during synthesis, the raw material mixing rate, crystallization temperature and crystallization time are controlled so as to effectively solve the problem of grain size control during the preparation of the ZSM-5 zeolite catalyst; and the mean grain size of the prepared zeolite catalyst is 3 to 7mu m, and the range of the grain size is 2.5 to 8mu m. The ZSM-5 zeolite catalyst prepared by the method can be used for the test of preparing cyclohexanol by cyclohexene hydration.

Description

A kind of preparation method of ZSM-5 zeolite catalyst technical field The invention relates to a ZSM-5 zeolite catalyst and a preparation method thereof. In particular, it relates to a particle size control method in the preparation process of ZSM-5 zeolite catalyst. technical background At present, the cyclohexene hydration catalyst has eliminated the early inorganic acids and ion exchange resins, and now the cyclohexene hydration production process basically uses solid molecular sieves, because they are insoluble in water, easy to separate and regenerate, and have high mechanical strength. And good heat resistance and other advantages, the most successful in industrial applications. Cyclohexene hydration reaction catalyst mostly uses ZSM-5 zeolite molecular sieve. ZSM-5 zeolite molecular sieve was first synthesized by Mobile Company in the United States in the early 1970s, and its general chemical formula is: 【M2(I), M(II)】O·Al2O3·nSiO2·mH2O In the formula, M2(I),...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B39/40B01J29/40C07C29/04C07C35/08

Inventor 金鑫张玉仙

Owner BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com