Preparation method of titanium dioxide with controllable particle size

A titanium dioxide and particle size control technology, applied in the field of nanomaterials, can solve problems such as difficulty in particle size control of nanometer titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

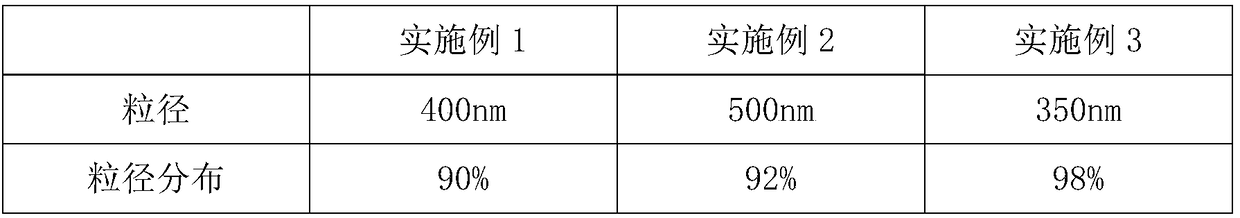

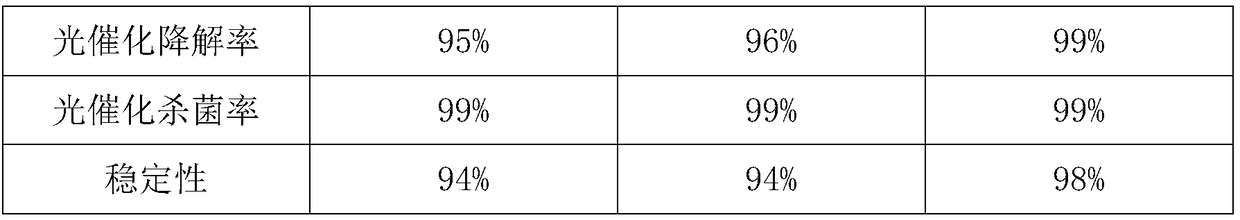

Embodiment 1

[0035] A method for preparing titanium dioxide with controllable particle size, comprising the steps of:

[0036] Step 1, adding ethyl cellulose to absolute ethanol, stirring until completely dissolved to obtain a dispersed alcohol solution;

[0037] Step 2, slowly drop n-butyl titanate into the dispersed alcohol solution, stir evenly and then stand at low temperature to obtain titanium alcohol solution;

[0038] Step 3, adding methyl cellulose to the titanium alcohol solution and ultrasonically dispersing to form a precipitation solution;

[0039] Step 4, slowly drop distilled water into the precipitation solution and stir evenly at low temperature until the addition is completed, then conduct ultrasonic reaction at low temperature for 2 hours, heat ultrasonic reaction for 2 hours, and obtain a suspension sol at constant temperature;

[0040] Step 5, after filtering the suspension sol solution, washing with absolute ethanol at constant temperature to obtain a gel;

[0041] ...

Embodiment 2

[0052] A method for preparing titanium dioxide with controllable particle size, comprising the steps of:

[0053] Step 1, adding ethyl cellulose to absolute ethanol, stirring until completely dissolved to obtain a dispersed alcohol solution;

[0054] Step 2, slowly drop n-butyl titanate into the dispersed alcohol solution, stir evenly and then stand at low temperature to obtain titanium alcohol solution;

[0055] Step 3, adding methyl cellulose to the titanium alcohol solution and ultrasonically dispersing to form a precipitation solution;

[0056] Step 4, slowly drop distilled water into the precipitation solution and stir evenly at low temperature until the addition is completed, then conduct ultrasonic reaction at low temperature for 4 hours, heat ultrasonic reaction for 4 hours, and obtain a suspension sol at constant temperature;

[0057] Step 5, after filtering the suspension sol solution, washing with absolute ethanol at constant temperature to obtain a gel;

[0058] ...

Embodiment 3

[0069] A method for preparing titanium dioxide with controllable particle size, comprising the steps of:

[0070] Step 1, adding ethyl cellulose to absolute ethanol, stirring until completely dissolved to obtain a dispersed alcohol solution;

[0071] Step 2, slowly drop n-butyl titanate into the dispersed alcohol solution, stir evenly and then stand at low temperature to obtain titanium alcohol solution;

[0072] Step 3, adding methyl cellulose to the titanium alcohol solution and ultrasonically dispersing to form a precipitation solution;

[0073] Step 4, slowly drop distilled water into the precipitation solution and stir evenly at low temperature until the addition is completed, then conduct ultrasonic reaction at low temperature for 3 hours, heat ultrasonic reaction for 3 hours, and obtain a suspension sol at constant temperature;

[0074] Step 5, after filtering the suspension sol solution, washing with absolute ethanol at constant temperature to obtain a gel;

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com