Application and preparation method of ZSM-5 molecular sieve with mesopores and micropores

A technology of ZSM-5 and molecular sieve, which is applied in the field of catalyst preparation, can solve the problems of economy, high environmental protection cost, complex synthesis procedure, molecular sieve loss, etc., and achieve the effect of low cost, simple synthesis method and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

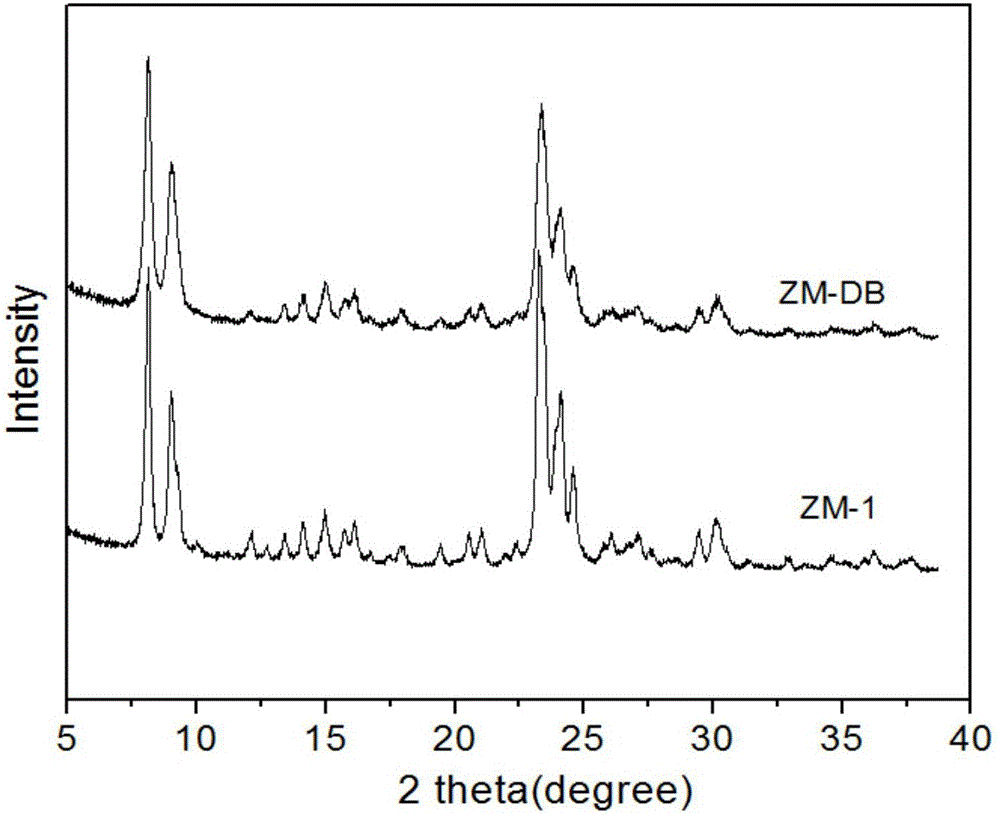

[0042] Stir and mix Tetraethyl Silicate (TEOS), Tetrapropylamine Hydroxide (TPAOH), Aluminum Isopropoxide, and Deionized Water in a molar ratio of 1:0.28:0.03:15, and then add 30wt% of silicon oxide Polyethylene glycol-1000 was used to make a homogeneous sol, and aged at 100°C for 12 hours to obtain a precursor.

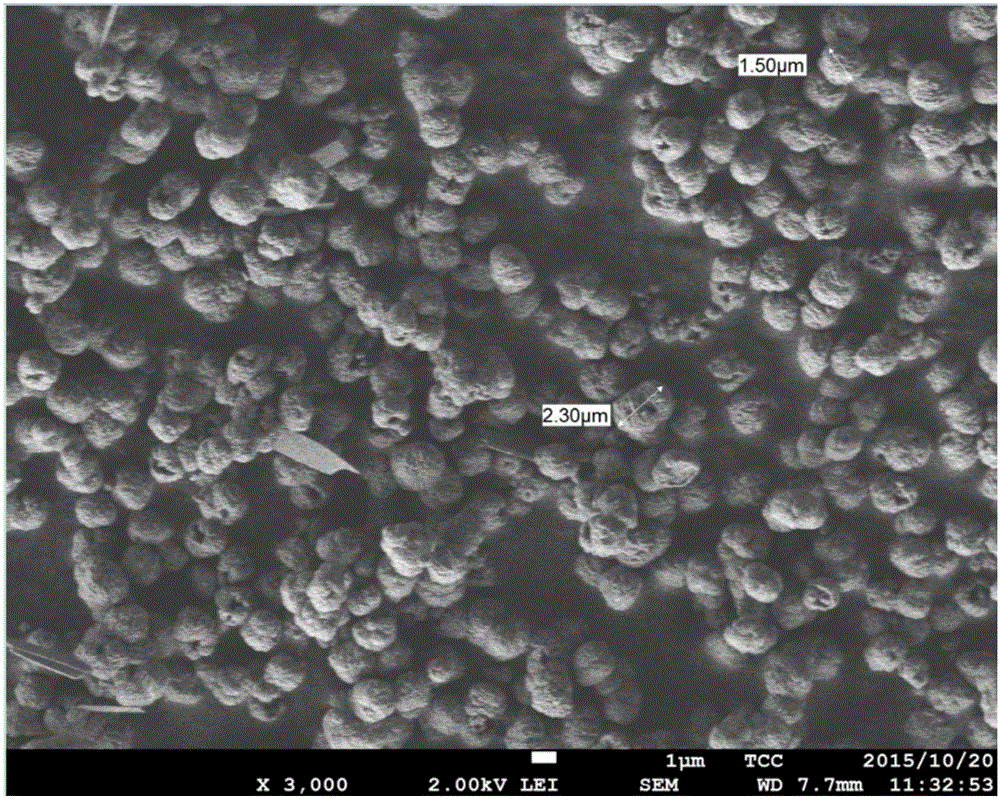

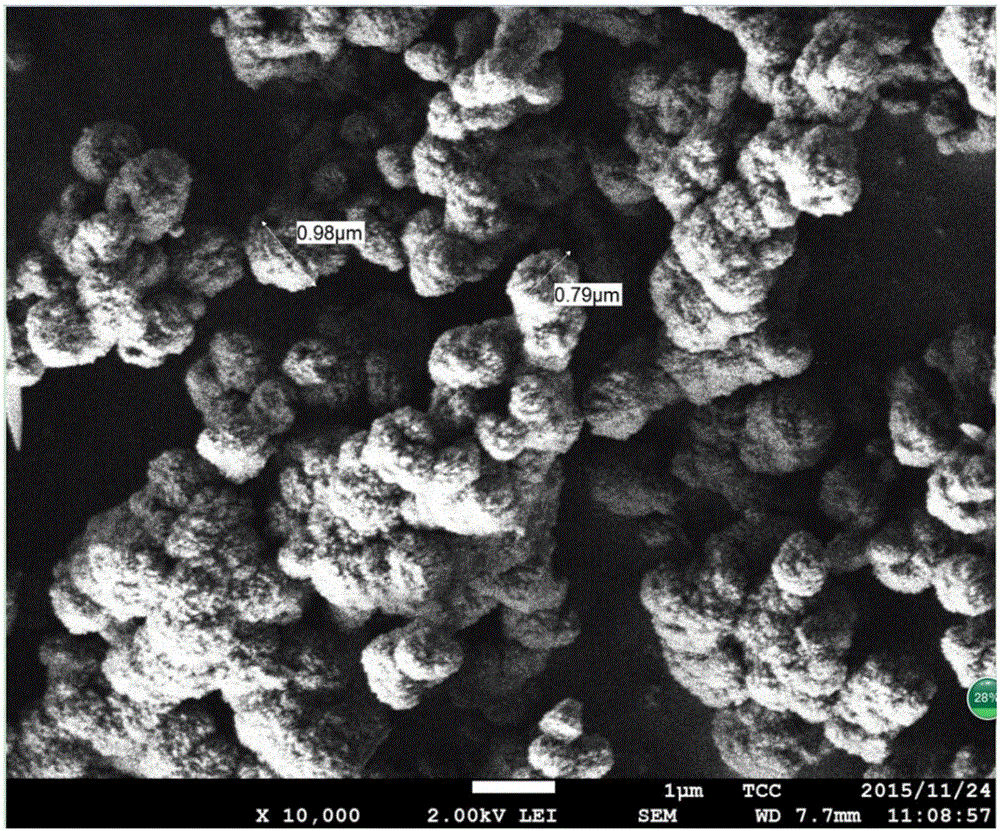

[0043] 150g silica sol (industrial grade, SiO 2 ≥30wt%) was dispersed in 60g of desalinated water, then 80g of NaOH solution with a mass fraction of 15% was added, and fully stirred at room temperature for 0.5 hour to prepare A solution; Mix with aluminum sulfate octadecahydrate, stir and fully dissolve at room temperature for 0.5 hours to prepare solution B; slowly add solution B to solution A, stir thoroughly at room temperature for 1 hour to form a uniform gel, and then transfer the gel to a synthesis kettle , aged with stirring at 100°C for 12h, then heated to 170°C for 20h with stirring and crystallized, cooled to room temperature, filtered and washed. The fil...

Embodiment 2

[0045] Repeat Example 1, but change tetrapropylammonium hydroxide to tetrapropylammonium bromide and polyethylene glycol-1000 to polyethylene glycol-4000 when preparing the precursor. The ZSM-5 sample was obtained after adding the precursor to the silica-alumina gel, which was marked as ZM-2. The relative crystallinity was 98%, and the crystal phase was similar to Example 1. The scanning electron microscope showed that the sample particle size was about 1 μm, spherical The morphology and surface are relatively rough, and the specific surface area of the nitrogen physical adsorption test sample is 540m 2 / g, the total pore volume is 0.37cm 3 / g.

Embodiment 3

[0047] Repeat Example 1, but change polyethylene glycol-1000 to starch when preparing the precursor. The ZSM-5 sample was obtained after adding the precursor to the silica-alumina gel, which was marked as ZM-3. The relative crystallinity was 96%, and the crystal phase was similar to Example 1. The scanning electron microscope showed that the particle size of the sample was about 1-2 μm. , spherical shape, and the surface is relatively rough. The specific surface area of the nitrogen physical adsorption test sample is 552m 2 / g, the total pore volume is 0.35cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com