Silica-alumina hydrogel double-coated modified ammonium polyphosphate and application thereof to inflaming retarding polypropylene

A technology of flame-retardant polypropylene and ammonium polyphosphate, which is applied in the field of flame-retardant materials, can solve the problems of reduced flame-retardant performance and heat-resistant performance, and achieve high flame-retardant efficiency, thermal stability, and improved flame-retardant performance. The effect of flame and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

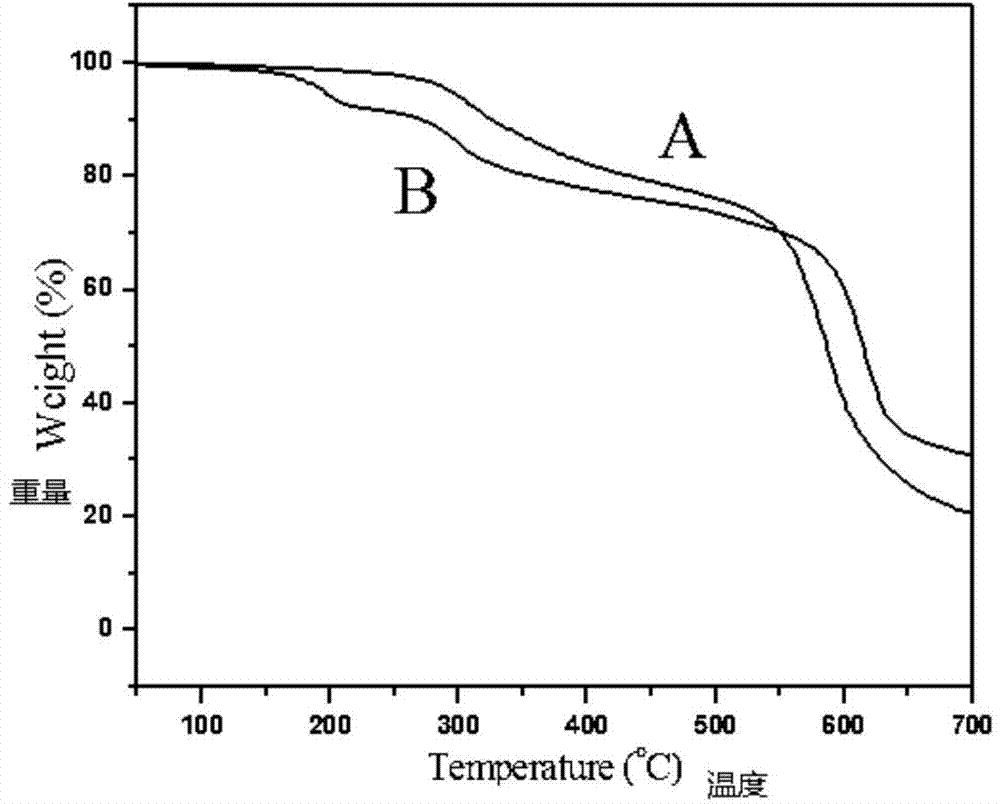

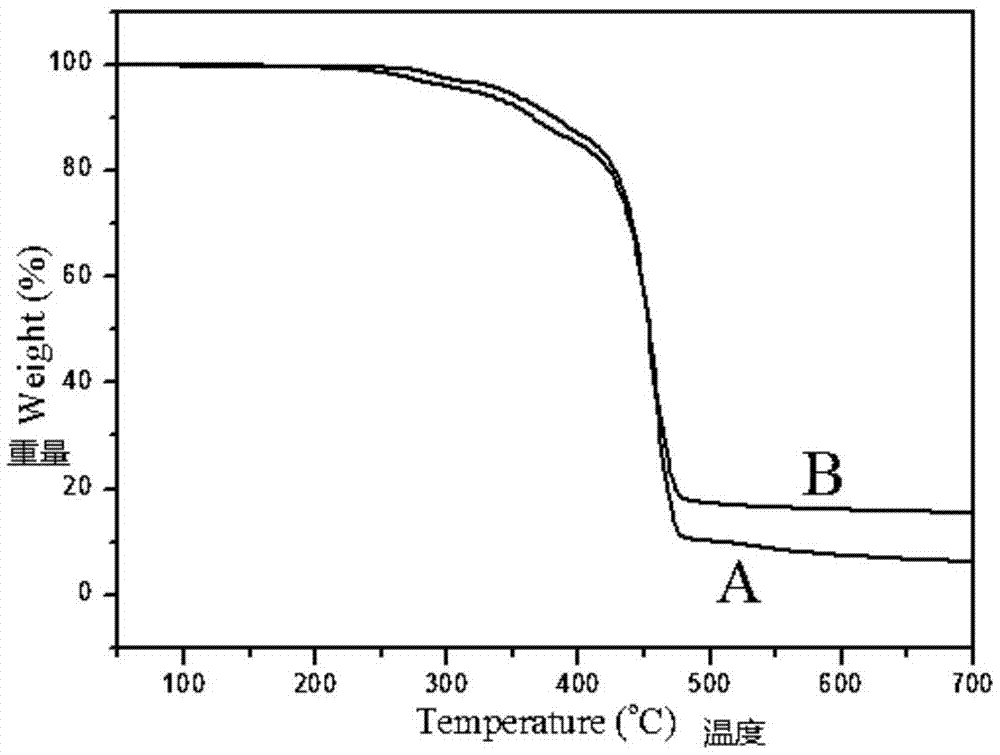

[0024] Preparation method of silica-alumina hydrogel double-coated modified ammonium polyphosphate:

[0025] (1) Add 300g of ammonium polyphosphate, 450mL of absolute ethanol and 3g of surfactant (OP-10) into a 1000mL three-necked flask equipped with a reflux condensing device, a thermometer and a mechanical stirrer, and the three-necked flask is placed in a water bath Heat while stirring, raise the temperature to 50°C, adjust the pH value between 9.5 and 10.5 with ammonia water, stir for 20 minutes, and the stirring speed is 250r / min. Made into ammonium polyphosphate slurry.

[0026] (2) Prepare a solution with 30 g of tetraethyl orthosilicate and 45 mL of deionized water, and adjust the pH value between 9.5 and 10.5 with ammonia water. This solution was poured into the ammonium polyphosphate slurry, and the reaction was stirred for 120 minutes.

[0027] (3) 45g of aluminum nitrate and 60g of deionized water were formulated into a solution, and the pH value was adjusted bet...

Embodiment 2

[0032] The preparation method of the silica-alumina hydrogel double-coated modified ammonium polyphosphate is the same as that in Example 1.

[0033] Application of coated modified ammonium polyphosphate for flame retardant polypropylene:

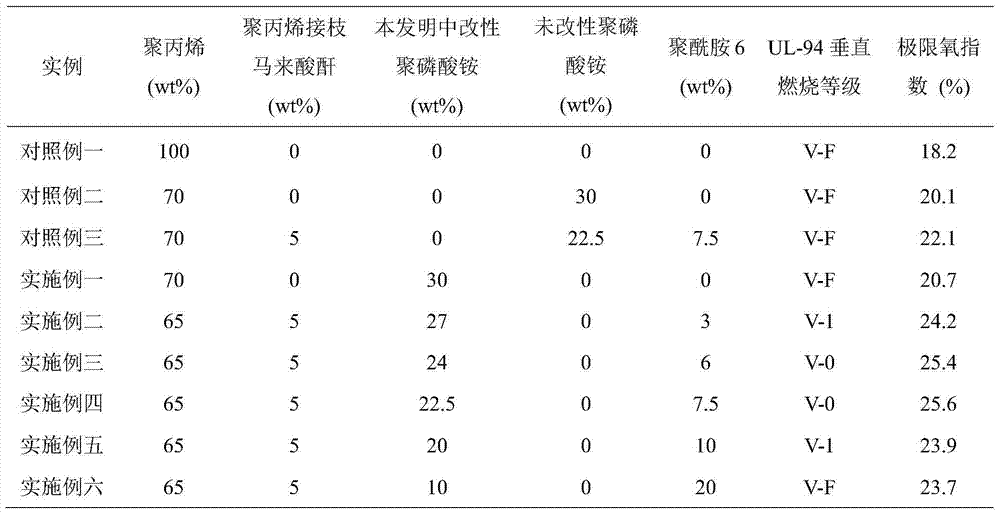

[0034] 65 parts by weight of dry polypropylene, 5 parts by weight of polypropylene grafted maleic anhydride, 27 parts by weight of silica-alumina hydrogel double-layer coated modified ammonium polyphosphate and 3 parts by weight of polyamide 6 in a mixer After fully mixing in the medium, use a twin-screw extruder to knead and granulate. The temperature range of the extruder is 180-250°C (the lowest end temperature of the extruder is 180°C, and the highest end temperature is 250°C), and the screw speed is 150rpm. Finally, the masterbatch of composite flame-retardant polypropylene material is obtained. After the masterbatch is dried, it is injection molded into a standard test sample with an injection molding machine. The injection molding t...

Embodiment 3

[0036] The preparation method of the silica-alumina hydrogel double-coated modified ammonium polyphosphate is the same as that in Example 1.

[0037] Application of coated modified ammonium polyphosphate for flame retardant polypropylene:

[0038] 65 parts by weight of dry polypropylene, 5 parts by weight of polypropylene grafted maleic anhydride, 24 parts by weight of silica-alumina hydrogel double-layer coated modified ammonium polyphosphate and 6 parts by weight of polyamide 6 in a mixer After fully mixing in the medium, use a twin-screw extruder to knead and granulate. The temperature range of the extruder is 180-250°C (the lowest end temperature of the extruder is 180°C, and the highest end temperature is 250°C), and the screw speed is 150rpm. Finally, the masterbatch of composite flame-retardant polypropylene material is obtained. After the masterbatch is dried, it is injection molded into a standard test sample with an injection molding machine. The injection molding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com