Synthesis method of beta/Y composite molecular sieve

A technology of composite molecular sieve and beta molecular sieve, which is applied in the field of molecular sieve catalytic material synthesis, and can solve the problem that the composite degree of the composite molecular sieve is difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 11.3g of sodium hydroxide, 65mL of distilled water, 5.8mL of sodium aluminate, and 33mL of water glass into a beaker, shake vigorously, and age at 30°C for 24h to obtain the Y structure-directing agent.

[0029] (2) Mix 2mL of the Y structure-directing agent obtained in step (1) with 1g of β molecular sieve, and let stand at 25°C for 8h.

[0030] (3) Dissolve 0.5 mL of sodium aluminate and 0.7 g of sodium hydroxide in 50 mL of distilled water, add 0.2 g of white carbon black after the dissolution is complete, and stir vigorously for 25 min; then add the Y structure-directing agent obtained in step (2) and The β molecular sieve mixture was vigorously stirred for 30 minutes; then it was placed in a closed reaction kettle and crystallized in an oven at 90°C for 24 hours. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120° C. for 12 hours, and the obtained sample was the β / Y composite molecular sieve.

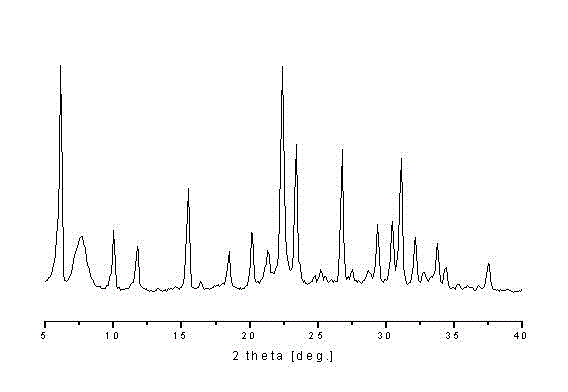

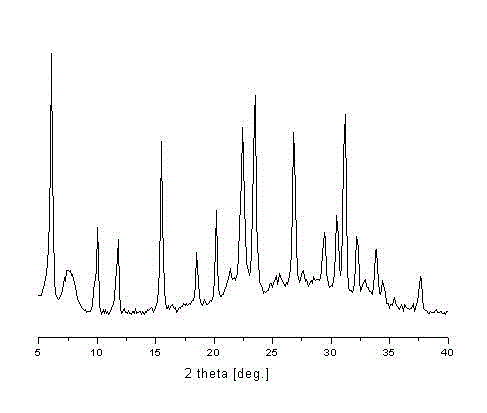

[0031] From the XRD ...

Embodiment 2

[0033] (1) Add 12.5g of sodium hydroxide, 60mL of distilled water, 5.8mL of sodium aluminate, and 31mL of water glass into a beaker, shake vigorously, and age at 35°C for 15h to obtain the Y structure-directing agent.

[0034] (2) Mix 2.5mL of the Y structure-directing agent obtained in step (1) with 1g of β molecular sieve, and let it stand at 25°C for 10h.

[0035] (3) Dissolve 0.4 mL of sodium aluminate and 0.8 g of sodium hydroxide in 60 mL of distilled water, add 0.4 mL of water glass after the dissolution is complete, and stir vigorously for 30 min; then add the Y structure-directing agent obtained in step (2) and β The molecular sieve mixture was vigorously stirred for 30 minutes; then it was placed in a closed reaction kettle and crystallized in an oven at 95°C for 20 hours. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120° C. for 12 hours, and the obtained sample was the β / Y composite molecular sieve.

Embodiment 3

[0037] (1) Add 13g of sodium hydroxide, 70mL of distilled water, 4.5mL of sodium aluminate, and 30mL of water glass into a beaker, shake vigorously, and age at 30°C for 24h to obtain the Y structure-directing agent.

[0038] (2) Mix 3mL of the Y structure-directing agent obtained in step (1) with 1.5g of β molecular sieve, and let stand at 25°C for 7h.

[0039] (3) Dissolve 0.5 mL of sodium aluminate and 0.9 g of sodium hydroxide in 50 mL of distilled water, add 0.6 g of silica sol after the dissolution is complete, and stir vigorously for 30 min; then add the Y structure-directing agent obtained in step (2) and β The molecular sieve mixture was vigorously stirred for 30 minutes; then it was placed in a closed reaction kettle and crystallized in an oven at 85°C for 29 hours. The obtained product was washed 4 times with distilled water to neutrality, and dried at 120° C. for 12 hours, and the obtained sample was the β / Y composite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com