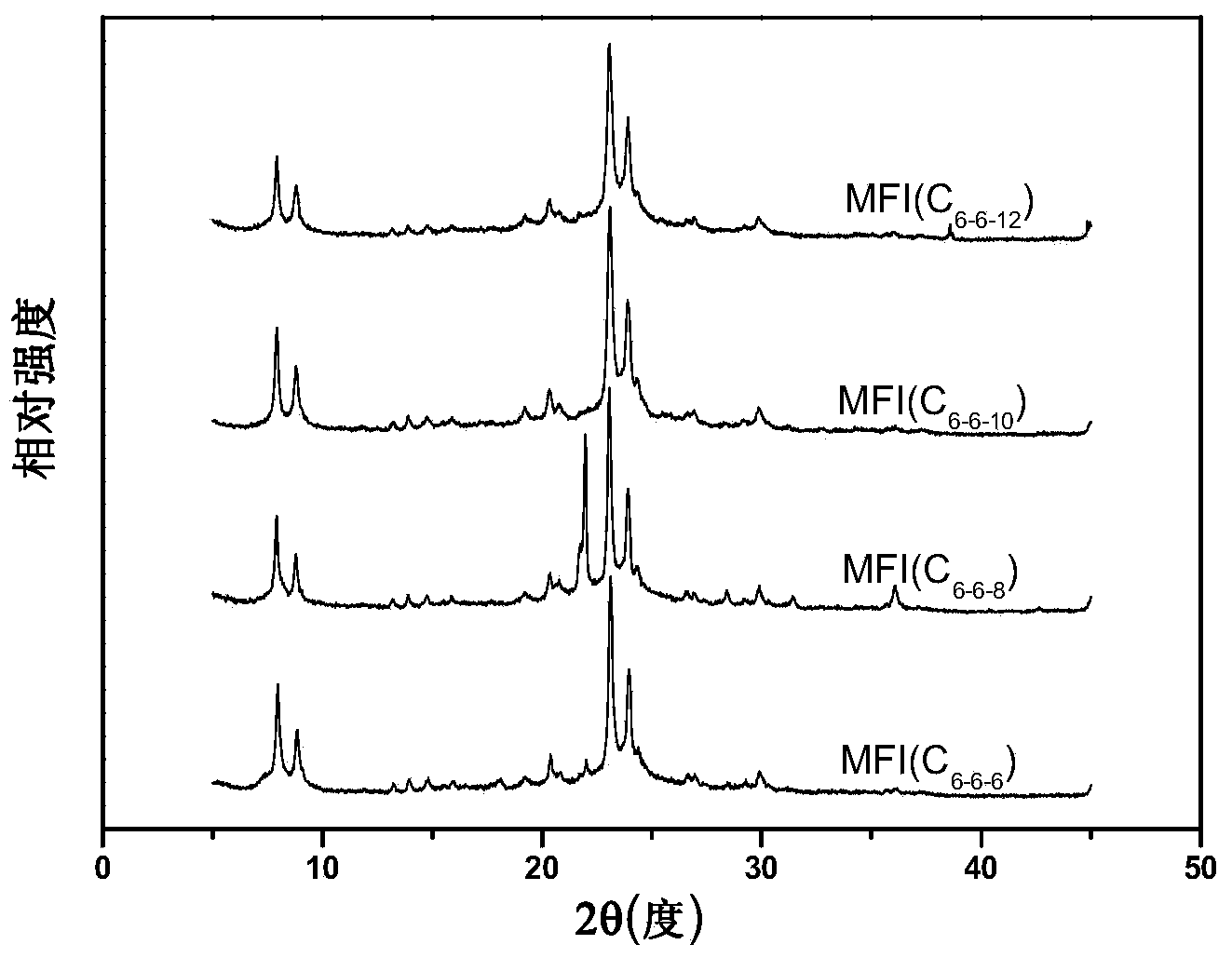

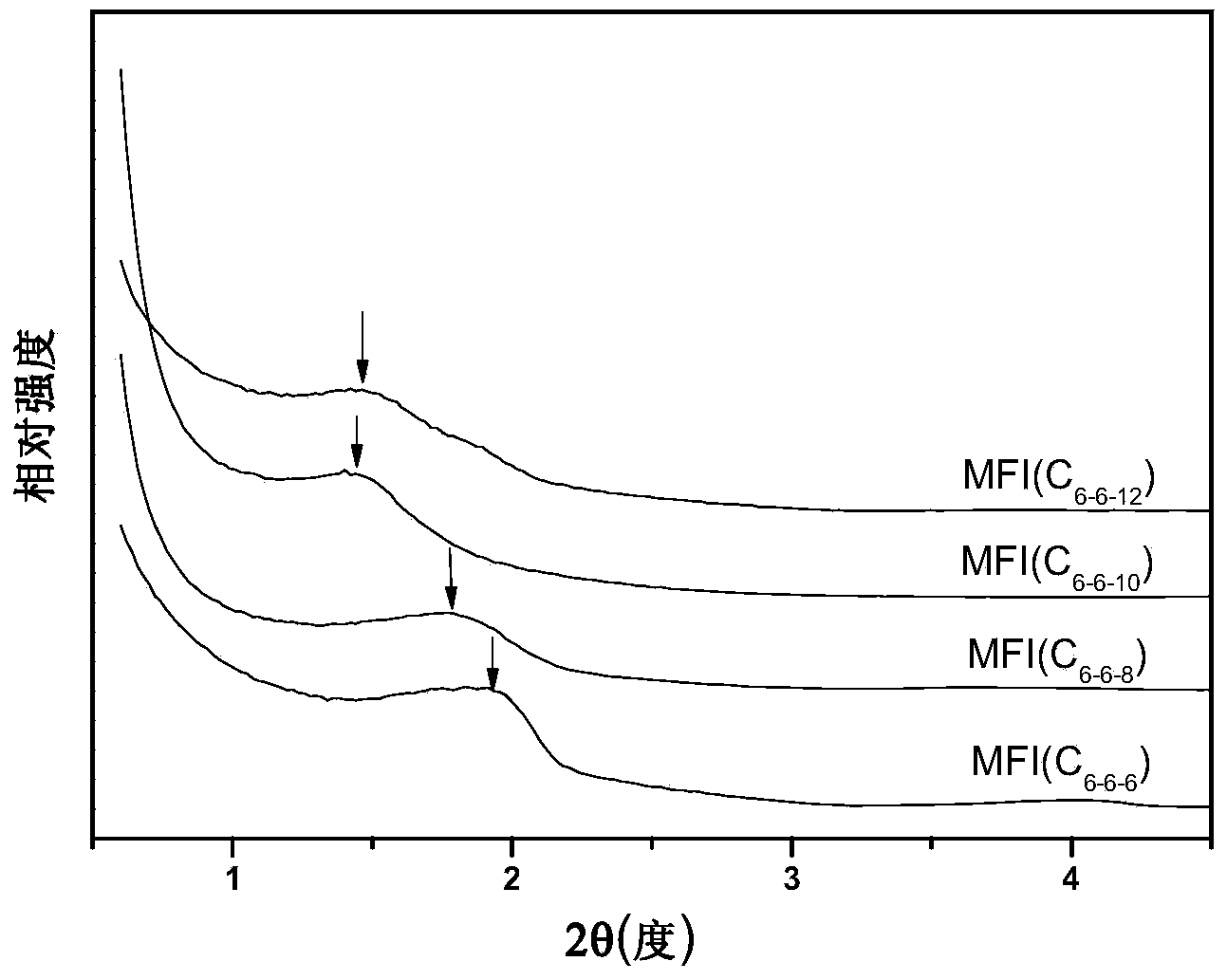

Preparation method of MFI micro-mesoporous lamellar molecular sieve with different interlayer spacings

A medium-micro double-porous, interlayer-spacing technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of framework destruction crystallinity, few types of template agents, uneven mesopores, etc., and achieves low cost, simple process and wide range of The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Mix 0.18g sodium hydroxide, 0.031g sodium metaaluminate, 0.889g four-head rigid Bola surfactant (C 6-6-6 Br 4 ) and 13.5mL of water were stirred to obtain a milky white solution, and the stirring was continued at 60°C for 1 hour;

[0036] (2) Slowly add 3.986g tetraethyl orthosilicate (98%, J£K) dropwise to the milky white solution prepared in step (1) under magnetic stirring at 60°C to obtain a silica-alumina gel, and after aging at room temperature for 10 minutes, Keep the silica-alumina gel at 60°C and continue to stir for 6h;

[0037] (3) Put the product of step (2) into a sealed stainless steel reaction kettle, and crystallize at 150°C for 168 hours. After the crystallization is completed, the solid is suction filtered and washed with deionized water, then vacuum-dried at 120°C for 10 hours, and then Calcined at 550° C. for 6 hours in a muffle furnace to remove the organic template agent, and obtain MFI sheet molecular sieves with a hierarchical pore structur...

Embodiment 2

[0039] (1) Mix 0.3g sodium hydroxide, 0.0513g sodium metaaluminate, 1.552g four-head rigid Bola surfactant (C 6-6-8 Br 4 ) and 22.5mL of water were stirred to obtain a milky white solution, and the stirring was continued at 60°C for 1 hour;

[0040] (2) Slowly add 6.643g tetraethyl orthosilicate (98%, J£K) dropwise to the milky white solution prepared in step (1) under magnetic stirring at 60°C to obtain a silica-alumina gel, and after aging at room temperature for 10 minutes, Keep the silica-alumina gel at 60°C and continue to stir for 6h;

[0041] (3) Put the product of step (2) into a sealed stainless steel reaction kettle, and crystallize at 150°C for 168 hours. After the crystallization is completed, the solid is suction filtered and washed with deionized water, then vacuum-dried at 120°C for 10 hours, and then Calcined at 550° C. for 6 hours in a muffle furnace to remove the organic template agent, and obtain MFI sheet molecular sieves with a hierarchical pore structur...

Embodiment 3

[0043] (1) Mix 0.36g sodium hydroxide, 0.062g sodium metaaluminate, 1.946g four-head rigid Bola type surfactant (C 6-6-10 Br 4 ) and 27mL of water were stirred to obtain a milky white solution, and the stirring was continued at 60°C for 1 hour;

[0044] (2) Slowly add 7.972g tetraethyl orthosilicate (98%, J£K) dropwise to the clear solution obtained in step (1) under magnetic stirring at 60°C to obtain a silica-alumina gel. After aging at room temperature for 10 minutes, the The silica-alumina gel was kept at 60°C and continued to stir for 6h;

[0045] (3) Put the product of step (2) into a sealed stainless steel reaction kettle, and crystallize at 150°C for 168 hours. After the crystallization is completed, the solid is suction filtered and washed with deionized water, then vacuum-dried at 120°C for 10 hours, and then Calcined at 550° C. for 6 hours in a muffle furnace to remove the organic template agent, and obtain MFI sheet molecular sieves with a hierarchical pore struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com