Method for extracting aluminum oxide and white carbon black through two-step alkaline leaching method by adopting high-alumina fly ash

A high-alumina fly ash and alumina technology, applied in the direction of alumina/aluminum hydroxide, silica, silica, etc., can solve the problems of demanding corrosion resistance of equipment and high energy consumption in the process, and avoid high temperature The effect of sintering, reducing material consumption, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

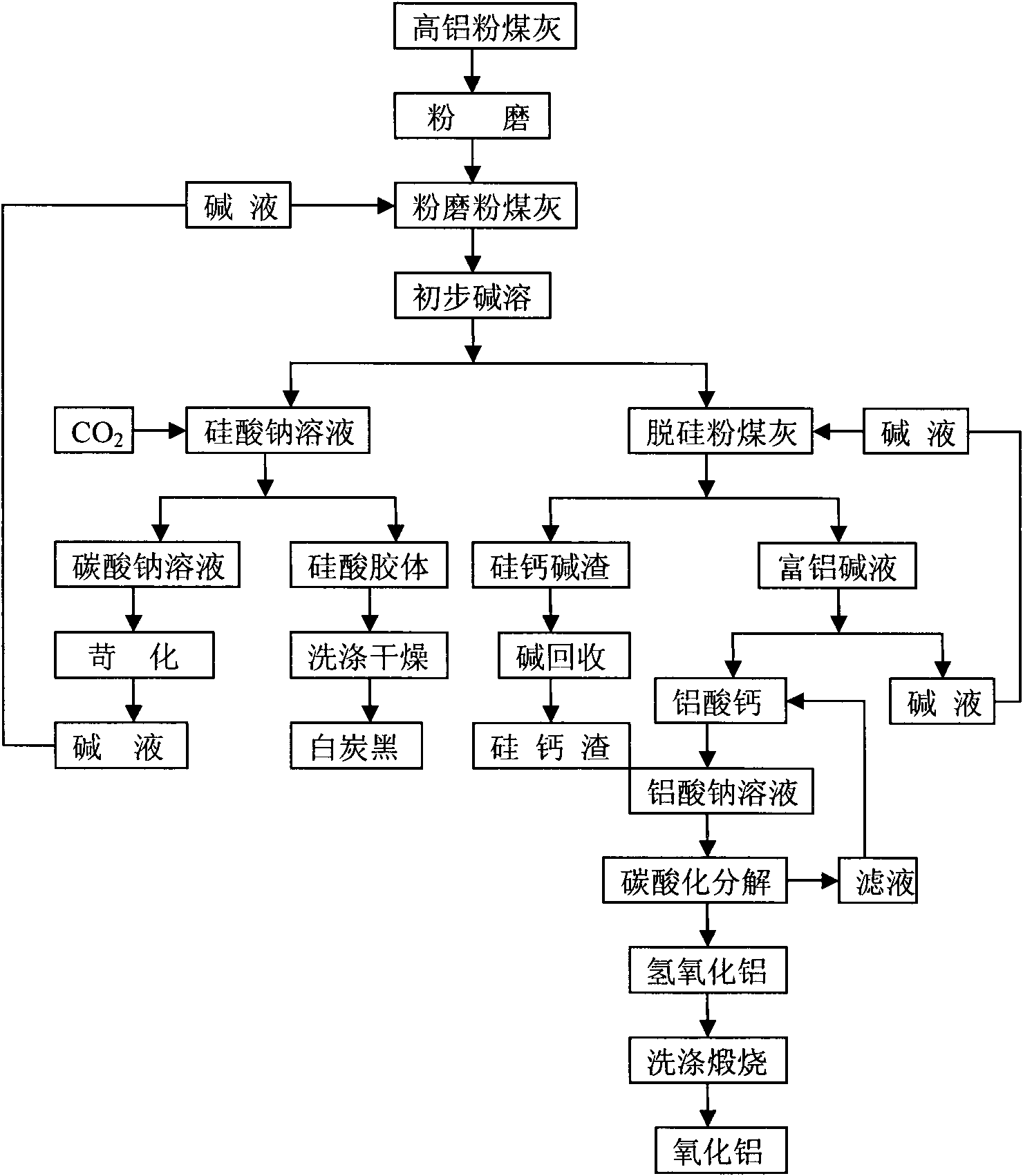

[0039] The process flow chart of extracting alumina and white carbon black by the high-aluminum fly ash two-step alkali dissolution method of the present invention is as follows figure 1 shown. exist figure 1 The following 9 steps (1)-(9) can be clearly seen in:

[0040] (1) the step of grinding high-alumina fly ash into pulverized fly ash;

[0041] (2) Carrying out preliminary alkali dissolution of pulverized coal ash to obtain sodium silicate solution and desiliconized fly ash;

[0042] (3) CO 2 Passing through the sodium silicate solution to obtain the sodium carbonate solution and the silicic acid colloid, and washing and drying the silicic acid colloid to obtain white carbon black;

[0043] (4) the step of obtaining lye by causticizing the sodium carbonate solution, and returning the lye to carry out preliminary alkali dissolution for grinding fly ash;

[0044] (5) mixing desiliconized fly ash, lime and lye, and carrying out two-step alkali dissolution to make the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com