Method for synthetizing ZSM-35 molecular sieve by seed crystal process

A technology of ZSM-35 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite and iron conglomerate crystalline aluminosilicate zeolite, etc., can solve the problems of increased synthesis cost, high reaction temperature, and long time, so as to reduce loss, The effect of large specific surface area and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Synthesis of ZSM-35 molecular sieve with RUB-37 as induced seed crystal

[0016] First, dissolve 0.078g of sodium aluminate in water, then add 0.182g of NaOH to it, after obtaining a clear solution, add 0.72g of white carbon black, continue stirring at room temperature until a uniform silica-alumina gel is formed, and finally add 0.036g of RUB- 37 Stir evenly, transfer the reaction raw materials to a polytetrafluoroethylene stainless steel reactor, and crystallize at 150°C for 3 days. The ratio of the reaction raw materials is as follows; SiO 2 : 0.08NaAlO 2 :0.38NaOH:35H 2 O: 5% RUB-37, the product was suction filtered and dried to obtain ZSM-35 molecular sieve.

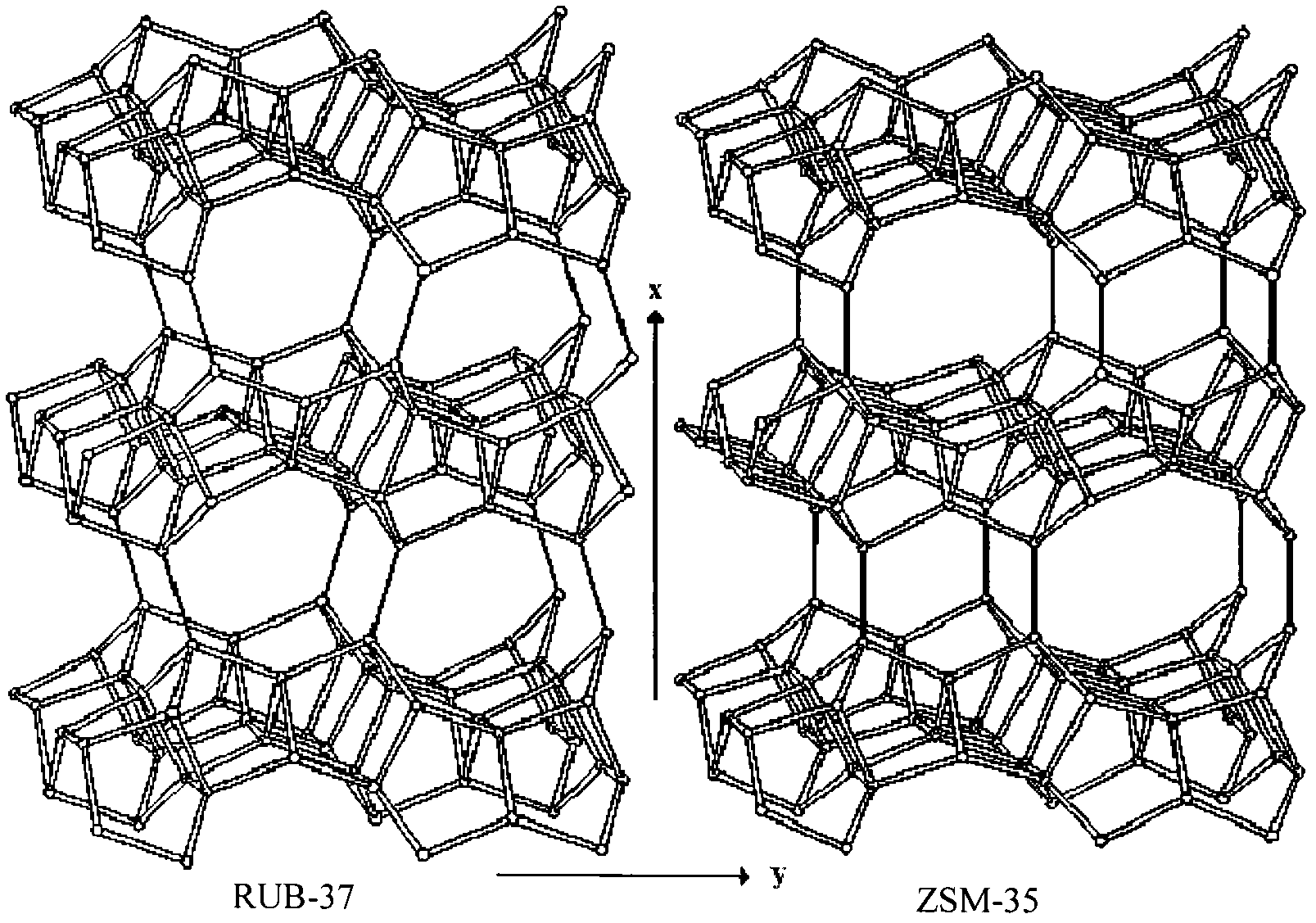

[0017] attached figure 1 It is the structural relationship between RUB-37 and ZSM-35. It can be seen from the figure that the two have the same structural unit, but the connection method is different.

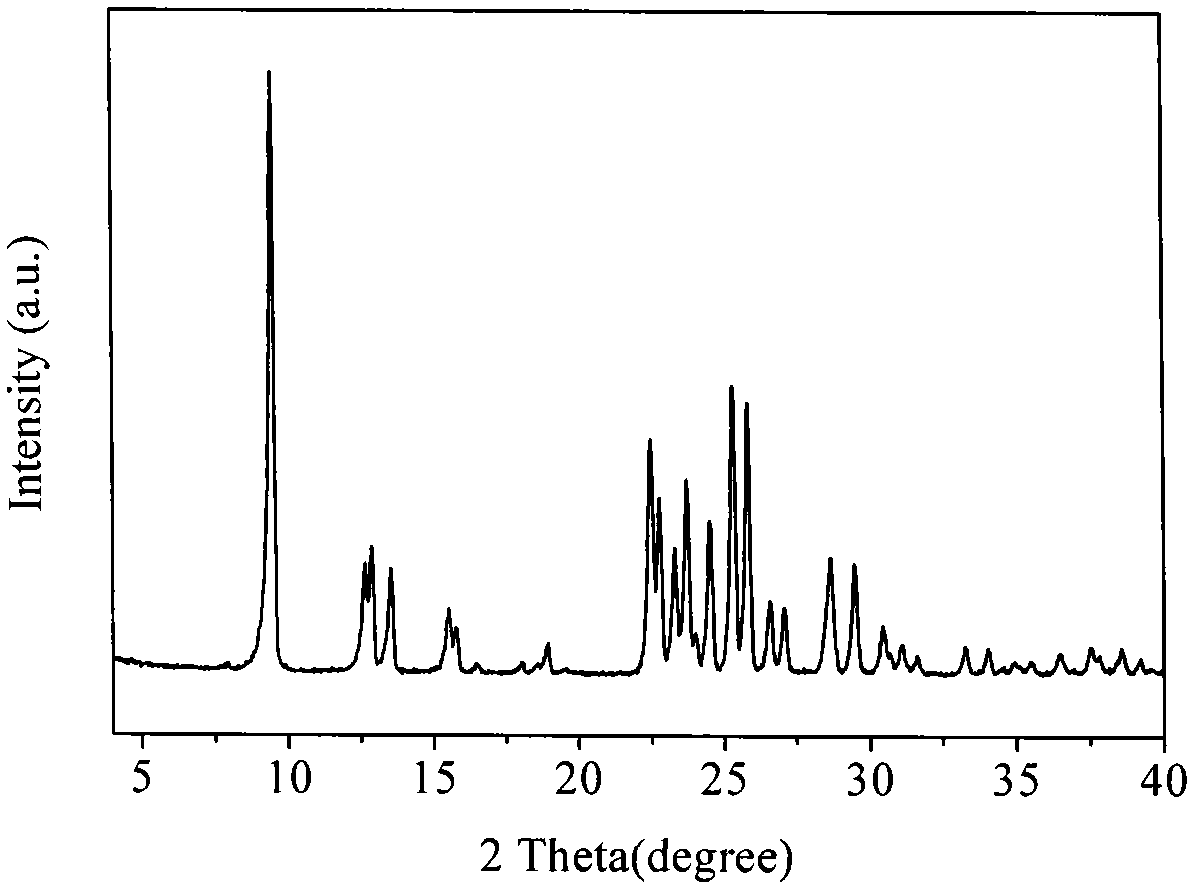

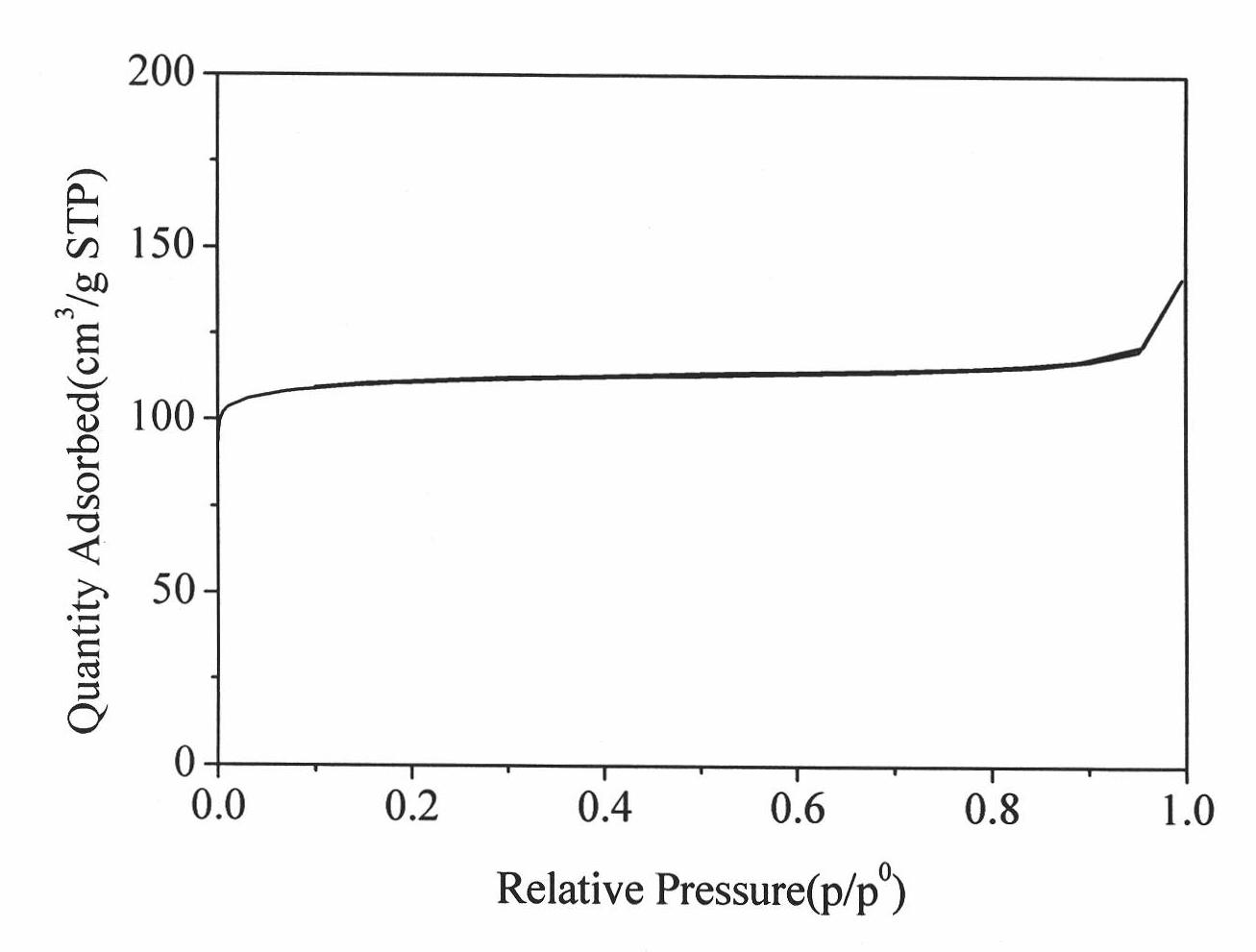

[0018] attached figure 2 It is the XRD pattern of the sample. It can be seen from the figu...

Embodiment 2

[0021] Example 2: Synthesis of ZSM-35 molecular sieve at 120°C with RUB-37 as the induced seed crystal

[0022] First, dissolve 0.088g of sodium aluminate in water, then add 0.192g of NaOH to it, after obtaining a clear solution, add 0.72g of white carbon black, continue stirring at room temperature until a uniform silica-alumina gel is formed, and finally add 0.036g of RUB- 37 Stir evenly, transfer the reaction raw materials to a polytetrafluoroethylene stainless steel reactor, and crystallize at 120°C for 10 days. The ratio of the reaction raw materials is as follows; SiO 2 : 0.09NaAlO 2 :0.4NaOH:35H 2 O: 5% RUB-37, the product was suction filtered and dried to obtain ZSM-35 molecular sieve.

Embodiment 3

[0023] Example 3: Synthesis of ZSM-35 molecular sieve with 3% RUB-37 as induced seed crystal

[0024] First, dissolve 0.088g of sodium aluminate in water, then add 0.172g of NaOH to it, add 0.72g of white carbon black after obtaining a clear solution, continue stirring at room temperature until a uniform silica-alumina gel is formed, and finally add 0.022g of RUB- 37 Stir evenly, transfer the reaction raw materials to a polytetrafluoroethylene stainless steel reactor, and crystallize at 150°C for 3 days. The ratio of the reaction raw materials is as follows; SiO 2 : 0.09NaAlO 2 :0.36NaOH:35H 2 O: 3% RUB-37, the product was suction filtered and dried to obtain ZSM-35 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com