Preparation method of low-alkaline liquid accelerating agent

A technology of quick-setting agent and liquid, which is applied in the field of preparation of low-alkali liquid quick-setting agent, which can solve the problems of obvious differences in mineral composition and affect the use of shotcrete, and achieve the effect of meeting the setting time requirements and good cement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

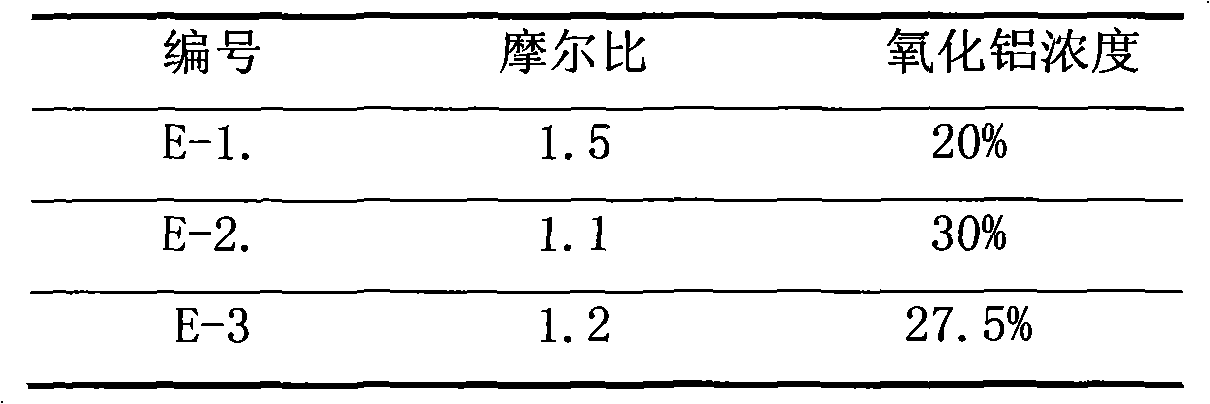

[0030] Dissolve 25 parts of solid sodium hydroxide into 43 parts of water, then add 32 parts of aluminum hydroxide to it at 80°C (the molar ratio of sodium hydroxide to aluminum hydroxide is 1.4), and react for 6 hours to obtain Al 2 o 3 Liquid sodium aluminate E-1 at a content of 20%. The reaction vessel is a three-necked flask with a thermometer and a reflux device.

preparation Embodiment 2

[0032] Dissolve 25 parts of solid sodium hydroxide into 30 parts of water, then add 45 parts of aluminum hydroxide to it at 100°C (the molar ratio of sodium hydroxide to aluminum hydroxide is 1.1), and react for 4 hours to obtain Al 2 o 3 30% liquid sodium aluminate E-2. The reaction vessel is a three-necked flask with a thermometer and a reflux device

preparation Embodiment 3

[0034] Dissolve 25 parts of solid sodium hydroxide into 33 parts of water, then add 42 parts of aluminum hydroxide to it at 130°C (the molar ratio of sodium hydroxide to aluminum hydroxide is 1.1), and react for 2 hours to obtain Al 2 o 3 Liquid sodium aluminate E-2. with a content of 27.5%. The reaction vessel is a three-necked flask with a thermometer and a reflux device

[0035] Table 1: Liquid Sodium Aluminate E1-E3

[0036]

[0037] 2. Liquid sodium aluminate modification

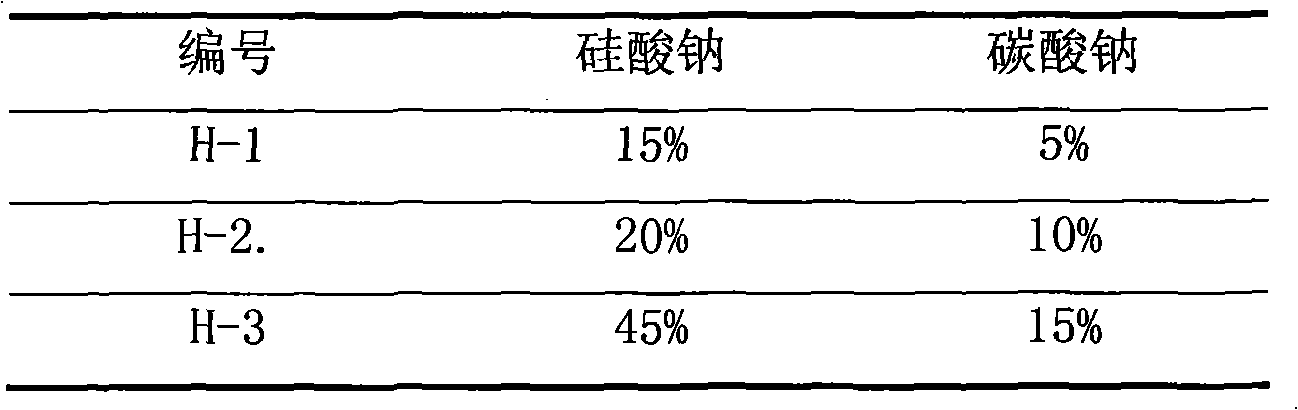

[0038] Configure sodium aluminate sodium silicate mixed solution according to Table 2

[0039] Table 2. Mixed solution of sodium silicate and sodium carbonate

[0040]

[0041] Liquid sodium aluminate modified embodiment 1

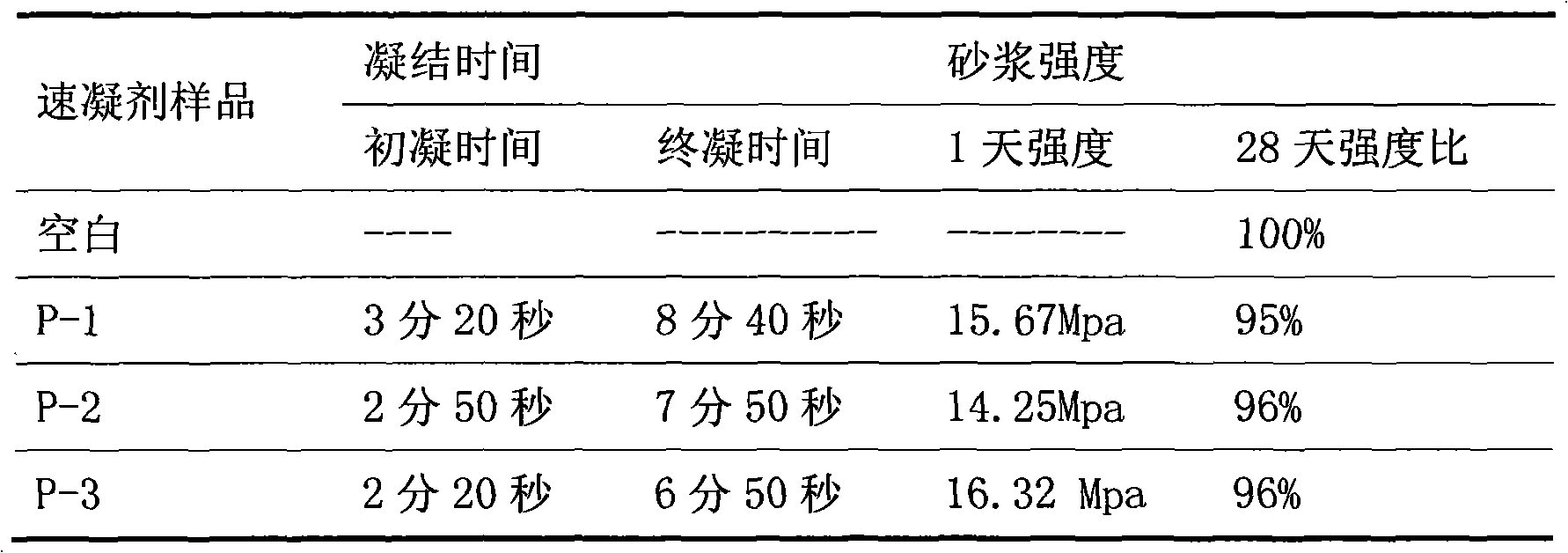

[0042] Under high shear stirring (1000S -1 ) state slowly add 50 parts of liquid sodium aluminate (E1) into 20 parts of H1 solution. When the gel appears, add 25 parts of water, continue to add the remaining liquid sodium aluminate solution after the gel dissolves, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com