A kind of preparation method of starch-based concrete water reducer

A concrete water-reducing agent and starch-based technology, applied in the field of concrete water-reducing agents, can solve the problems of longer induction period, lower water retention, environmental pollution, etc., and achieve simple preparation process, improved water reduction efficiency, and simple synthesis equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for preparing starch-based water reducer of the present invention comprises the following steps:

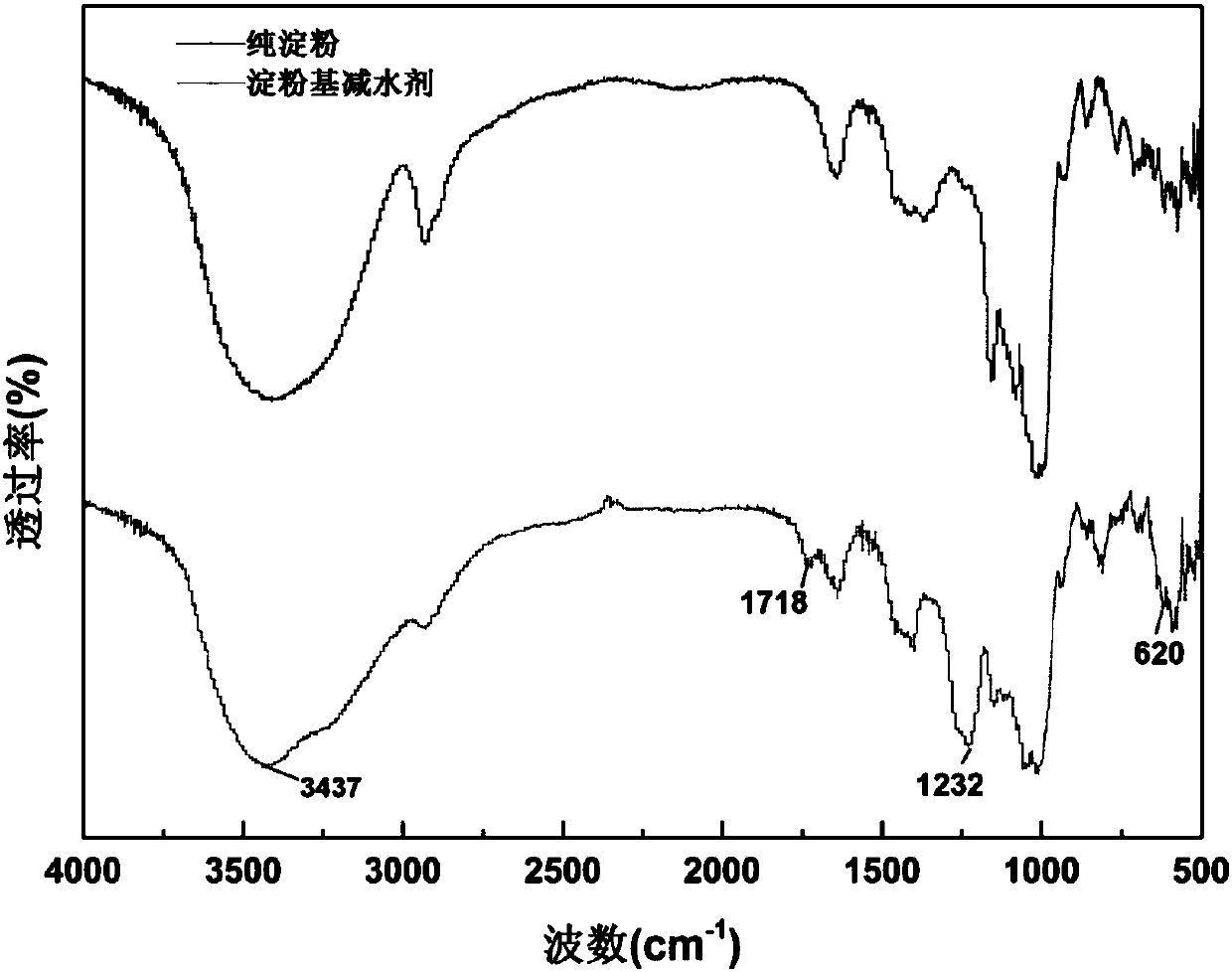

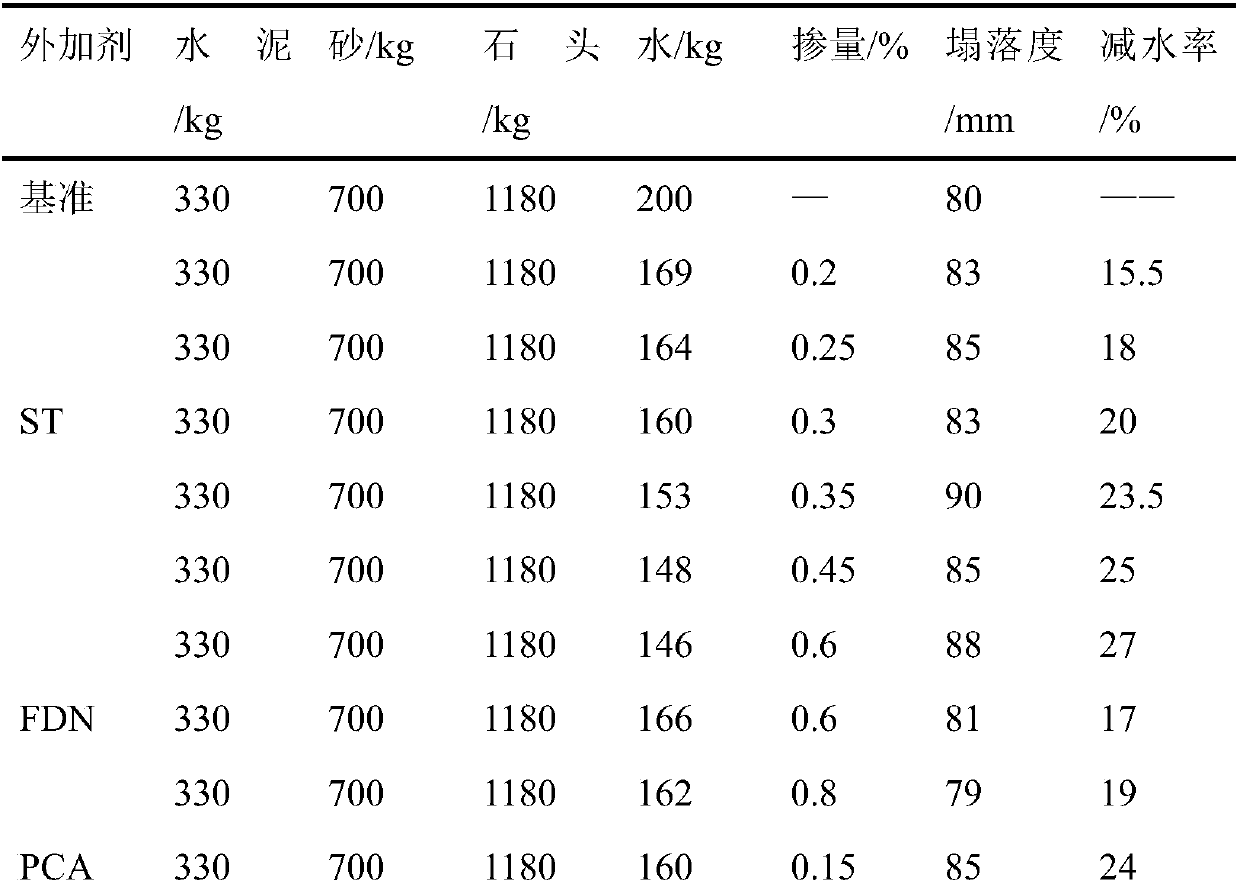

[0030] (1) Add water to industrial-grade starch common corn starch to prepare starch milk containing 30wt% starch, add concentrated sulfuric acid with 7% starch mass, then heat in a water bath to 55°C for hydrolysis reaction, stop heating after 2h, without neutralization, The residual sulfuric acid was kept, vacuum filtration was used, and the acid-thinned starch was obtained by freeze-drying at -5°C. (2) Mix and grind maleic anhydride, urea, and p-aminobenzenesulfonic acid, then add them to dry acid-thinned starch, and then add a small amount of water. The four are fully mixed, stirred evenly, and synthesized by a semi-dry method, that is, put Put it in an oven at 65°C for 1 hour, and then raise the temperature to 90°C. After reacting for 3 hours, take out the starch sample and grind it to obtain soluble grafted modified starch. The molar ratio of acid and wat...

Embodiment 2

[0034] The method for preparing starch-based water reducer of the present invention comprises the following steps:

[0035] (1) Add water to industrial-grade starch common wheat starch to prepare starch milk containing 35wt% starch, add concentrated sulfuric acid with 8% starch mass, then heat in a water bath to 55°C for hydrolysis reaction, stop heating after 2h, without neutralization, The residual sulfuric acid was kept, vacuum filtration was used, and the acid-thinned starch was obtained by freeze-drying at -5°C.

[0036] (2) Mix and grind maleic anhydride, urea, and p-aminobenzenesulfonic acid, then add them to dry acid-thinned starch, and then add a small amount of water to fully mix them. Put it in an oven at 65°C to react for 2 hours, raise the temperature to 100°C, and react for 3 hours, take out the starch sample, and grind to obtain soluble grafted modified starch, among which, acid-thinned starch, maleic anhydride, urea, p-aminobenzene The molar ratio of sulfonic ...

Embodiment 3

[0039] The method for preparing starch-based water reducer of the present invention comprises the following steps:

[0040] (1) Add water to the industrial-grade starch common tapioca starch to make starch milk containing 30wt% starch, add concentrated sulfuric acid with 9% starch mass, then heat in a water bath to 65°C for hydrolysis reaction, stop heating after 1h, without neutralization, The residual sulfuric acid was kept, vacuum filtration was used, and the acid-thinned starch was obtained by freeze-drying at -5°C.

[0041] (2) Mix and grind maleic anhydride, urea, and p-aminobenzenesulfonic acid, then add them to dry acid-thinned starch, and then add a small amount of water to fully mix them. Put it in an oven at 70°C to react for 2 hours. After raising the temperature to 90°C and react for 3.5 hours, take out the starch sample and grind it to obtain soluble grafted modified starch. Among them, acid-thinned starch, maleic anhydride, urea, p-amino The molar ratio of benz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com