Preparation method of cement dispersant containing polyamide-polyamino constitutional units

A cement dispersant and amide-containing polyamine technology, which is applied in the specific synthesis field of new amphoteric water reducers, can solve the problems of complex reaction process, long reaction cycle, and high energy consumption, and achieve simple operation, good economic benefits, and low reaction time. The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

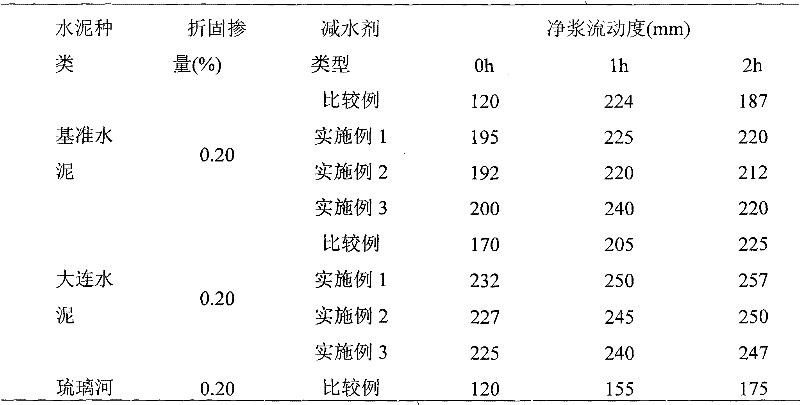

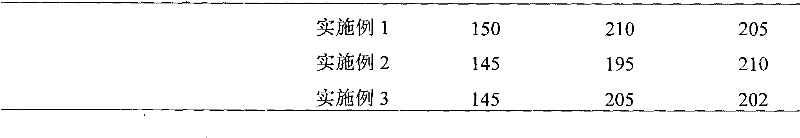

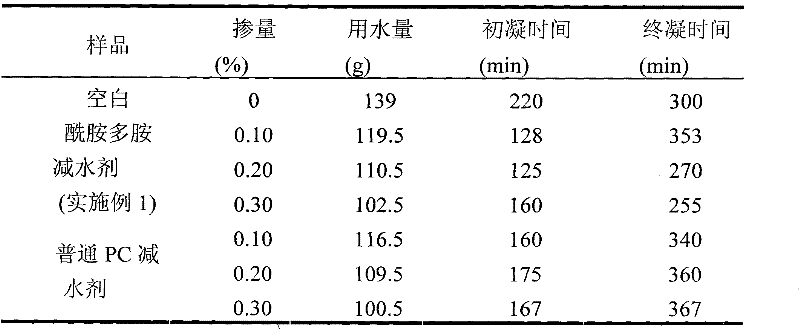

Embodiment 1

[0028] Add 103g of diethylenetriamine, 73g of adipic acid, and 2.0g of concentrated sulfuric acid (concentration 98%) into the reactor equipped with stirring, condensation, and reflux water outlet devices at normal temperature, raise the temperature to 90°C, and add 40g of cyclohexane , the temperature was raised to 150° C., and the generated water was removed during the reaction. The constant temperature was reacted for 4 hours, and the water yield was >110%. The cyclohexane was removed by vacuum to obtain adipate polyamide. In the second amidation, add 80g of polyamide adipate to the reactor, and when the temperature reaches 80°C, add 0.32g of hydroquinone as a polymerization inhibitor, react for 10 minutes, then add 11.6g of methacrylic acid, concentrated sulfuric acid (concentration 98%) 0.9g, cyclohexane 30g, heating up to 130°C, removing generated water while reacting, and obtaining amidopolyamine unit after 8 hours. During the radical polymerization process, 6.0 g of th...

Embodiment 2

[0030]Add 146g of triethylenetetramine, 72g of oxalic acid, and 5.0g of sulfamic acid to the reactor equipped with stirring, condensing, and reflux water outlet devices at room temperature, raise the temperature to 80°C, add 50g of benzene, and heat up to 120°C for reaction Remove the generated water at the same time, react at constant temperature for 7 hours, the water yield > 110%, and remove benzene by vacuuming to obtain oxalic acid polyamide. In the second amidation, add oxalic acid polyamide 70g in the reactor, the temperature is up to 90°C, add 0.08g of polymerization inhibitor diphenylamine, react for 15 minutes and then add acrylic acid 13.3g, sulfamic acid 0.83g, 40g of benzene was heated up to 110°C, and the generated water was removed during the reaction, and amide polyamine units were obtained after 3 hours. During the radical polymerization process, 6.3 g of the prepared amide polyamine, 27.2 g of methoxypolyethylene glycol acrylate and 41.7 g of water were added...

Embodiment 3

[0032] Add 189g of tetraethylenepentamine, 152.2g of sebacic acid, and 10g of p-toluenesulfonic acid to the reactor equipped with stirring, condensing, and reflux water outlet devices at room temperature, raise the temperature to 100°C, add 60g of toluene, and raise the temperature to 135°C During the reaction, the generated water was removed, and the reaction was carried out at a constant temperature for 12 hours, and the water yield was >110%, and the toluene was removed by vacuuming to obtain sebacic acid polyamide. In the second amidation, 90g of sebacic acid polyamide was added to the reactor, and the temperature was raised to 100°C, 0.008g of polymerization inhibitor phenothiazine was added, and after 20 minutes of reaction, 15.9g of methacrylic acid and p-toluenesulfonate were added. 1.76 g of acid and 50 g of toluene were heated up to 140°C, and the generated water was removed during the reaction, and amidopolyamine units were obtained after 4 hours. During the radical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com