Polycarboxylate water reducing agent by using water as solvent and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of polycarboxylate water reducer, can solve problems such as unpleasant and irritating odor, and achieve the effects of easy control of reaction conditions, simple preparation process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

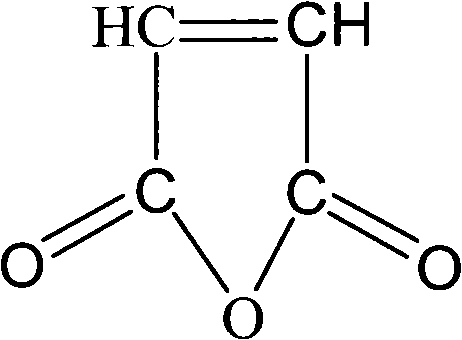

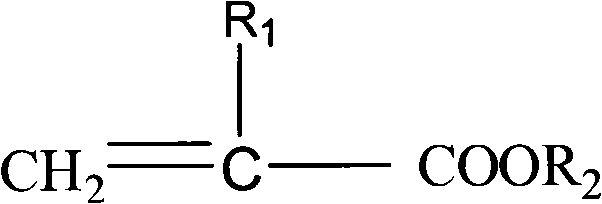

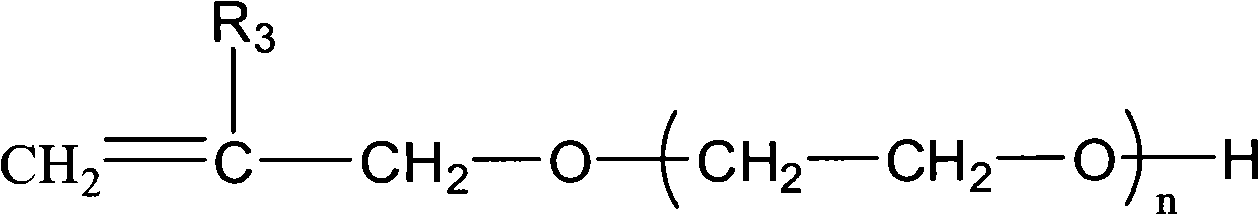

[0029] Add 19.61 g of maleic anhydride, 100 g of allyl polyglycol ether with a molecular weight of 2000 and 5.76 g of allyl sodium sulfonate into a four-necked flask, and add deionized water to dissolve. Heat up to 75°C, add dropwise the monomer solution prepared by 100g of allyl polyglycol ether with a molecular weight of 2000, 17.22g of methacrylic acid, 14.2g of acrylamide and deionized water, and 3g of ammonium persulfate The initiator solution prepared with deionized water was added dropwise in 3 hours. After 2 hours of heat preservation, the temperature was lowered to 30°C, and neutralized with 30% sodium hydroxide solution to Ph=7.0 to obtain the polycarboxylate superplasticizer PC -1.

Embodiment 2

[0031] Add 19.61 g of maleic anhydride, 100 g of allyl polyglycol ether with a molecular weight of 2000 and 14.4 g of allyl sodium sulfonate into a four-necked flask, and add deionized water to dissolve. Heat up to 85°C, add dropwise the monomers prepared from 100g of allyl polyglycol ether with a molecular weight of 2000, 14.4g of acrylic acid, 20.07g of 2-acrylamido-2-methylpropanesulfonic acid and deionized water solution, and the initiator solution prepared by 5g ammonium persulfate and deionized water, the dropwise addition was completed in 3 hours, and after 2 hours of heat preservation, the temperature was lowered to 30°C, and neutralized to Ph=7.0 with 40% sodium hydroxide solution to obtain Polycarboxylate superplasticizer PC-2.

Embodiment 3

[0033] Add 19.61 g of maleic anhydride, 120 g of allyl polyglycol ether with a molecular weight of 2400 and 12.6 g of sodium methacrylic sulfonate into a four-necked flask, and add deionized water to dissolve. Heat up to 70°C, add dropwise the monomer solution prepared by 120g of allyl polyglycol ether with a molecular weight of 2400, 17.29g of acrylic acid, 5.68g of acrylamide and deionized water, and 8g of ammonium persulfate and deionized water. The initiator solution prepared with ionized water was added dropwise in 2 hours. After 2 hours of heat preservation, the temperature was lowered to 30°C, and neutralized with 40% sodium hydroxide solution to Ph=7.0 to obtain the polycarboxylate water reducer PC-3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com