Organic silicon/saccharide co-modified polycarboxylate water reducing agent and preparation method thereof

A technology of organosilicon and co-modification, applied in the field of concrete external processing agent, can solve the problems of poor compatibility of concrete raw materials, single raw materials, non-renewable and other problems, and achieve the effect of improving cement adaptability, enhancing compatibility and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

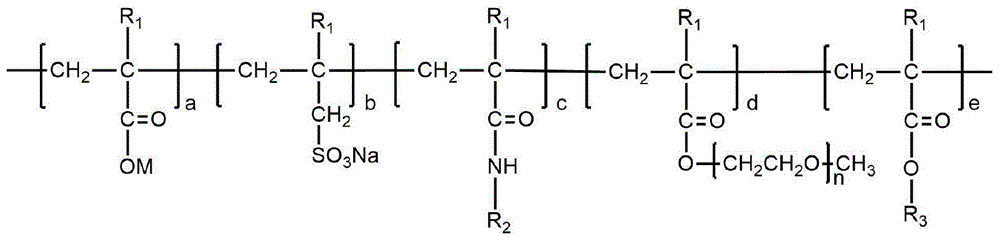

Method used

Image

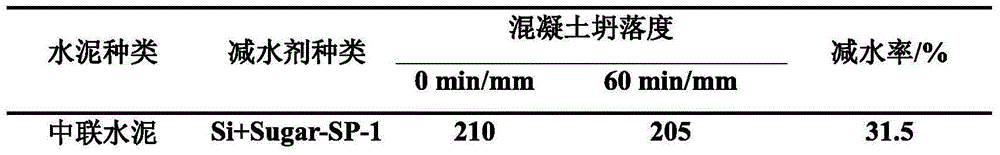

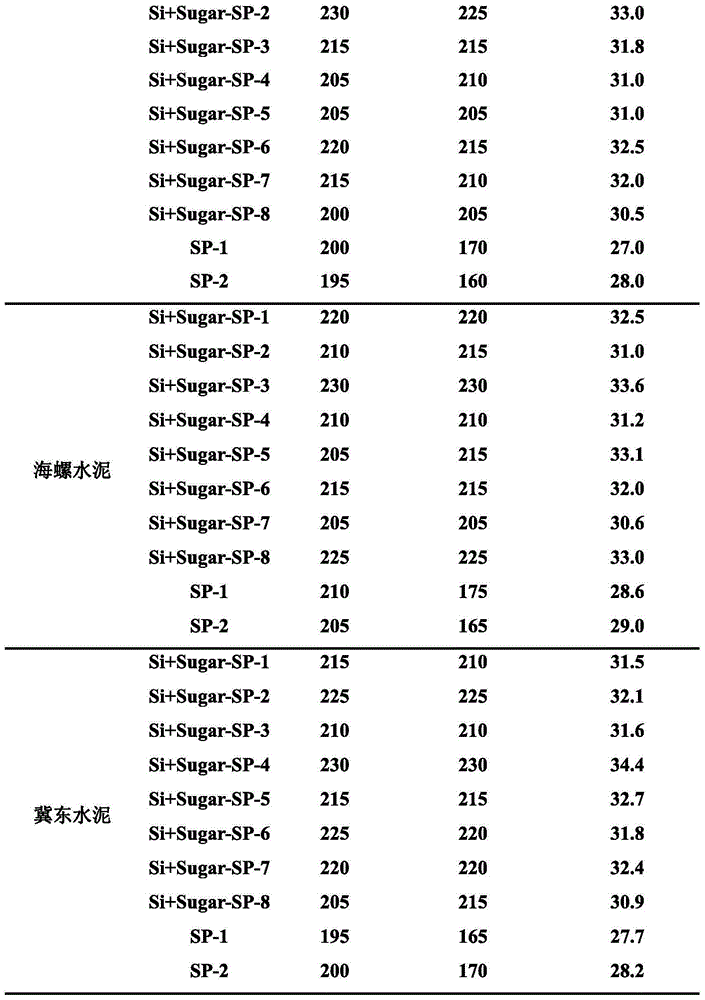

Examples

Embodiment 1

[0041] (1) Preparation of methoxypolyoxyethylene acrylate macromonomer

[0042] Add 1000.0g of methoxypolyethylene glycol with a molecular weight of 1000 and 72.1g of acrylic acid into the reactor, add 5.36g of p-toluenesulfonic acid and 0.54g of hydroquinone, stir and heat to 80°C for esterification for 10h, then distill The resulting water was removed to obtain the methoxypolyoxyethylene acrylate macromonomer.

[0043] (2) Preparation of silicone-modified acrylate macromonomer

[0044] Add 222.4g of aminoethylaminopropyltrimethoxysilane and 72.1g of acrylic acid into the reactor, add methanol solvent, and raise the temperature to reflux for 2 hours, and evaporate the solvent to obtain aminoethylaminopropyltrimethoxysilane Modified acrylate macromonomer.

[0045] (3) Preparation of sugar-modified acrylate macromonomer

[0046] Put 180.2g of glucose and 38.1g of acrylic acid into the reactor, add 1.09g of p-toluenesulfonic acid and 0.11g of hydroquinone, stir and heat to 70...

Embodiment 2

[0050] (1) Preparation of methoxypolyoxyethylene acrylate macromonomer

[0051] Add 1000.0g of methoxypolyethylene glycol with a molecular weight of 1000 and 360.5g of acrylic acid into the reactor, add 68.03g of p-toluenesulfonic acid and 6.80g of hydroquinone, stir and heat to 150°C for esterification for 2 hours, then distill The resulting water was removed to obtain the methoxypolyoxyethylene acrylate macromonomer.

[0052] (2) Preparation of silicone-modified acrylate macromonomer

[0053] Add 264.4g of aminoethylaminopropyltriethoxysilane and 216.3g of acrylic acid into the reactor, add ethanol solvent, and raise the temperature to reflux for 2 hours, and evaporate the solvent to obtain aminoethylaminopropyltriethoxy Silane-modified acrylate macromonomer.

[0054] (3) Preparation of sugar-modified acrylate macromonomer

[0055] Put 180.2g of fructose and 720.6g of acrylic acid into the reactor, add 45.04g of p-toluenesulfonic acid and 4.50g of hydroquinone, stir and h...

Embodiment 3

[0059] (1) Preparation of methoxypolyoxyethylene acrylate macromonomer

[0060] Add 1000.0g of methoxypolyethylene glycol with a molecular weight of 1000 and 216.2g of acrylic acid into the reactor, add 24.32g of p-toluenesulfonic acid and 2.43g of hydroquinone, stir and heat to 120°C for esterification for 5 hours, then distill The resulting water was removed to obtain the methoxypolyoxyethylene acrylate macromonomer.

[0061] (2) Preparation of silicone-modified acrylate macromonomer

[0062] Add 206.4g of aminoethylaminopropylmethyldimethoxysilane and 144.1g of acrylic acid into the reactor, add propanol solvent, and heat up to reflux reaction for 10h, and evaporate the solvent to obtain aminoethylaminopropyl Methyldimethoxysilane modified acrylate macromonomer.

[0063] (3) Preparation of sugar-modified acrylate macromonomer

[0064] Add 342.3g of lactose and 360.3g of acrylic acid into the reactor, add 21.08g of p-toluenesulfonic acid and 2.11g of hydroquinone, stir an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com